A kind of copper ion modified water treatment method

A copper ion and water treatment technology, applied in the field of water treatment, can solve the problems of difficulty in forming floatable carriers, limited ion adsorption or precipitation control process, and poor adaptability of complexed metal organic pollutants, so as to facilitate flotation separation and extraction , increase the particle size, strengthen the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

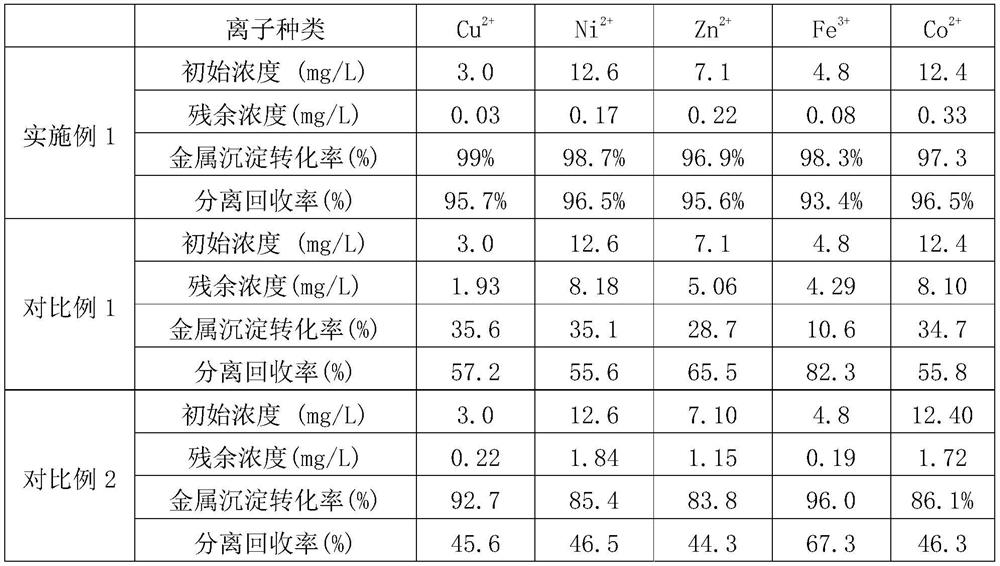

[0041] Cu in heavy metal ion wastewater from a smelter 2+ , Ni 2+ , Zn 2+ , Fe 3+ , Co 2+ The total ion concentration is 39.9mg / L, Cu 2+ The concentration is 3.02 mg / L, pH=8-9.

[0042] To the waste water containing metal ions, add 40 mg / L of copper ion modification regulator, wherein the copper ion modification regulator includes 10 parts by weight of copper sulfate and 2 parts by weight of ascorbic acid, stir, and carry out copper ion modification and adjustment for 10min; Add 80mg / L ammonium sulfide and stir evenly, carry out sulfide precipitation adjustment, react for 4 minutes to obtain a mixed slurry, continue to add 2mg / L sodium dodecyl sulfonate as a collector, and carry out flotation separation, the flotation separation time is 8min, flotation separation to obtain foam and purified water containing heavy metal components.

[0043] After being treated by the method of this embodiment, the concentration of each metal ion, the conversion rate of the precipitate and...

Embodiment 2

[0053] A mine processing plant produces backwater. After zinc sulfate is used to suppress zinc and lead separation, the floating lead tailings are activated by copper ions to recover zinc by flotation, and the backwater contains Cu. 2+ 0.5mg / L, Zn 2+ 2.0mg / L, when the return water is returned to the lead flotation process, it is difficult to obtain a better lead priority flotation index.

[0054] to contain Cu 2+ and Zn 2+ Add 2 mg / L copper ion modification regulator to the activated backwater of , react for 4min to obtain a mixed slurry, continue to add 20mg / L cetyltrimethylammonium bromide as a collector, carry out flotation separation, and the flotation separation time is 6min to obtain the treated backwater.

[0055] After treatment by the method of this embodiment, Cu in the backwater 2+ Concentration dropped to 0.01mg / L, Zn 2+ It is reduced to 0.4mg / L, which realizes the purification of the backwater of the concentrator with significant influence of metal ions.

[...

Embodiment 3

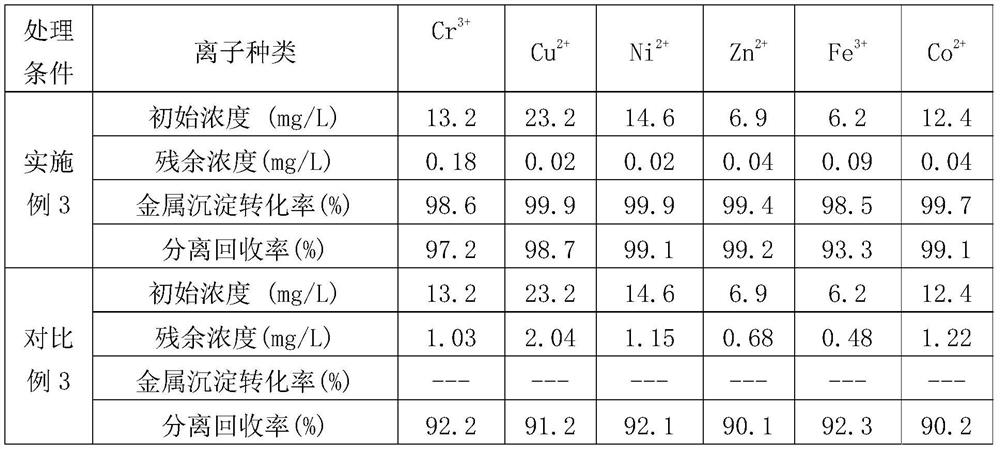

[0058] In a certain electroplating waste liquid, Cr 3+ , Cu 2+ , Fe 3+ , Ni 2+ , Zn 2+ , Co 2+ The content is shown in Table 2, and the pH is between 7.5-8.0.

[0059] To the wastewater containing metal ions, add 200 mg / L of copper ion modification regulator, wherein the copper ion modification regulator comprises 10 parts by weight of copper chloride, 50 parts by weight of ammonium chloride and 1 part by weight of hydroxylamine hydrochloride, stir, and carry out copper The ion modification was adjusted for 10min, then 60mg / L sodium sulfide was added to the solution modified by copper ions, stirred evenly, sulfide precipitation was adjusted, and the reaction was carried out for 4-6min to obtain a mixed slurry, and 3mg / L hexyl xanthogen was added continuously. Potassium acid was used as a collector for flotation separation, and the flotation separation time was 6 minutes, and the flotation separation obtained heavy metal component foam and purified water.

[0060] After b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com