A kind of preparation method and application of modified sepiolite

A sepiolite, modified technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. pollution and other problems, to achieve the effect of low price, shortening the time required for preparation, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

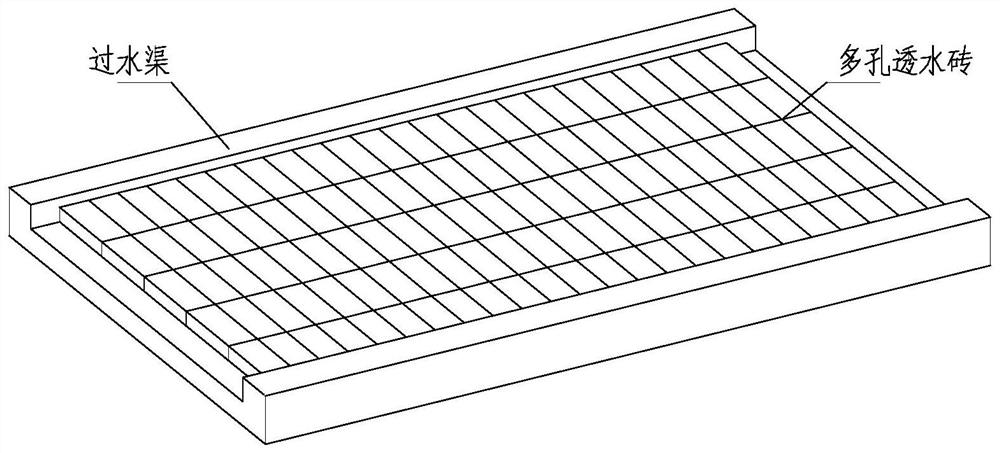

[0034] A preparation method of modified sepiolite permeable brick, comprising the steps of:

[0035] (1) Purchasing natural sepiolite is a raw material, and the natural sepiolite is pulverized into particles with a particle diameter of 1 cm;

[0036] (2) At room temperature, prepare 5mol / L hydrochloric acid, mix 1kg of sepiolite and 6kg of the aforementioned hydrochloric acid evenly, set the microwave to 250W, and modify for 1h;

[0037] (3) Separate sepiolite by gauze filtration, rinse with tap water until neutral, and dry to semi-dry at 80-100°C;

[0038] (4) Mix 50 g of sodium chloride, 25 g of zinc sulfate, 68 g of sucrose, and 1000 g of water to make a mixed salt solution.

[0039](5) Immerse 210g of acid-modified sepiolite in 680g of mixed salt solution, under the assistance of microwave (250W~350W), stir and modify for 3h, then filter the semi-modified sepiolite with gauze, and put it in the ventilation air-dried to half-dried;

[0040] (6) Putting the semi-modified ...

Embodiment 2

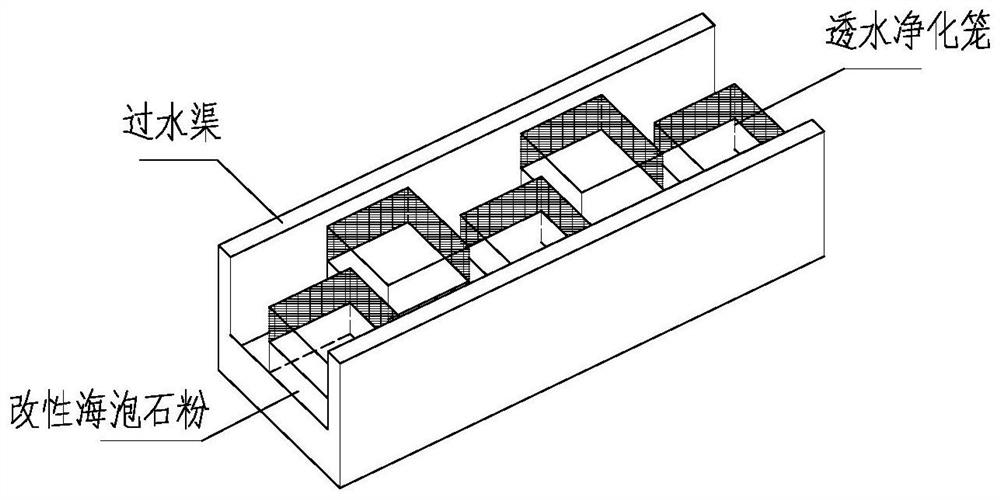

[0046] A preparation method of a modified sepiolite water-permeable purification cage, comprising the steps of:

[0047] (1) taking natural sepiolite as raw material, pulverizing natural sepiolite into particles with a particle diameter of 1 cm;

[0048] (2) At room temperature, prepare 5mol / L hydrochloric acid, mix 1kg of sepiolite with 5kg of the aforementioned hydrochloric acid, set the microwave to 300W, and modify for 1h;

[0049] (3) Separate sepiolite by gauze filtration, rinse with tap water until neutral, and dry to semi-dry at 80-100°C;

[0050] (4) Sodium chloride 50g, zinc sulfate 20g, sucrose 70g, water 1000g mix uniformly and make mixed salt solution;

[0051] (5) Submerge 200g of acid-modified sepiolite in 600g of mixed salt solution, under the assistance of microwave (250W~350W), stir and modify for 3h, and separate the semi-modified sepiolite by gauze filtration;

[0052] (6) drying the semi-modified sepiolite to semi-dry, putting it into a 300°C muffle furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com