A kind of preparation method of low temperature denitration catalyst supported by expanded graphite base carrier

An expanded graphite, carrier-supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., can solve the problems of weak interaction, difficult to achieve efficient and stable loading, etc. , Excellent NOx removal efficiency, ensure the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a low-temperature denitration catalyst loaded on an expanded graphite-based carrier, the process flow chart is as follows figure 1 shown, including the following steps:

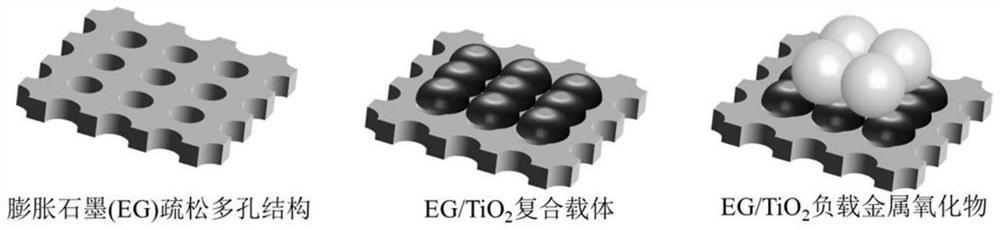

[0040] A. Take an appropriate amount of 200-mesh expanded graphite in a crucible, and bake it at 450°C for 2 hours. The resulting expanded graphite structure is as follows: figure 2 The expanded graphite (EG) loose porous structure shown;

[0041] B, the expanded graphite processed in step A is added to the solution A containing tetrabutyl titanate, ethanol and glacial acetic acid in a volume ratio of 2:8:1 according to the ratio of 1:80.75 to tetrabutyl titanate mass ratio, Sonicate for 15 minutes and then stir for 30 minutes, then add solution C containing ethanol, water and dilute nitric acid (20% by mass) in a volume ratio of 1:1:0.01, which is equivalent to 2 times the volume of tetrabutyl titanate, into solution A , dried overnight at 120°C after standing for 18h and th...

Embodiment 2

[0046] A kind of preparation method of the low-temperature denitration catalyst supported by expanded graphite base carrier, comprises the following steps:

[0047] A. Take an appropriate amount of 200-mesh expanded graphite in a crucible, and bake it at 450°C for 2 hours;

[0048] B, the expanded graphite after processing is joined in the solution B that contains 1% sucrose (mass fraction) first ultrasonic 15min stirs 30min again, then the suspension solution D that is equivalent to solution B 2 times volumes containing titanium dioxide (expanded graphite and Titanium dioxide (mass ratio: 1:19) was added to Solution B, left to age for 18 hours, dried overnight at 120°C and calcined at 450°C for 5 hours to obtain an expanded graphite-based carrier.

[0049] C, manganese salt (manganese acetate), iron salt (ferric nitrate nonahydrate) are dissolved in methanol solution (methanol:water=1:1) according to the mass ratio of 1:1, form metal salt solution after stirring for 30min for...

Embodiment 3

[0053] A kind of preparation method of the low-temperature denitration catalyst supported by expanded graphite base carrier, comprises the following steps:

[0054] A. Take an appropriate amount of 200-mesh expanded graphite in a crucible, and bake it at 450°C for 2 hours;

[0055] B, the expanded graphite processed in step A is added to the solution A containing tetrabutyl titanate, ethanol and glacial acetic acid in a volume ratio of 2:8:1 according to the ratio of 1:420.75 to tetrabutyl titanate mass ratio, Sonicate for 15 minutes and then stir for 30 minutes, then add solution C containing ethanol, water and dilute nitric acid (20% by mass fraction) in a volume ratio of 1:1:0.01 equivalent to tetrabutyl titanate into solution A, After static aging for 12 hours, it was dried overnight at 120° C. and calcined at 450° C. for 4 hours to obtain an expanded graphite-based carrier.

[0056] C. Dissolve manganese salt (manganese nitrate tetrahydrate) and iron salt (ferric nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com