Woven reinforced degradable polyurethane elastomer artificial blood vessel and preparation method thereof

A polyurethane elastomer and artificial blood vessel technology, which is applied in the field of artificial blood vessels, can solve the problems of lack of availability, stay, and small-diameter artificial blood vessels have not yet appeared, and achieves the effects of low price, good mechanical properties, and a simple and efficient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

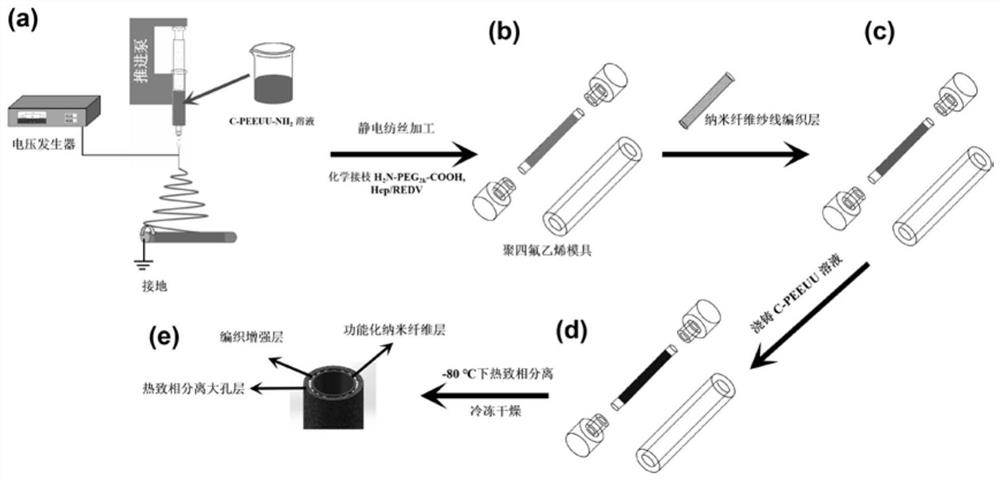

[0040] The invention provides a method for preparing a braided reinforced degradable polyurethane elastomer artificial blood vessel, comprising the following steps:

[0041] Step 1, mixing and dissolving one or several masterbatches among PLGA, PDO, and PGA to obtain a composite spinning solution;

[0042] Step 2, spinning the above-mentioned composite spinning solution using a double-needle counter-jet electrospinning system to obtain nanofiber yarns, and weaving the nanofiber yarns into tubular braids;

[0043] Step 3, Spin the stainless steel of the mold through electrospinning technology, first spin PEO (polyethylene oxide) nanofibers, and then spin C-PEEUU-NH 2 nanofibers; the loaded PEO, C-PEEUU-NH 2 The stainless steel with nanofibers was demolded in ultrapure water; the C-PEEUU-NH 2 The nanofiber tubular scaffold was stirred and washed in ultrapure water until the surface impurities were removed, and then vacuum freeze-dried;

[0044] Step 4, using activated H 2 N-...

Embodiment 1

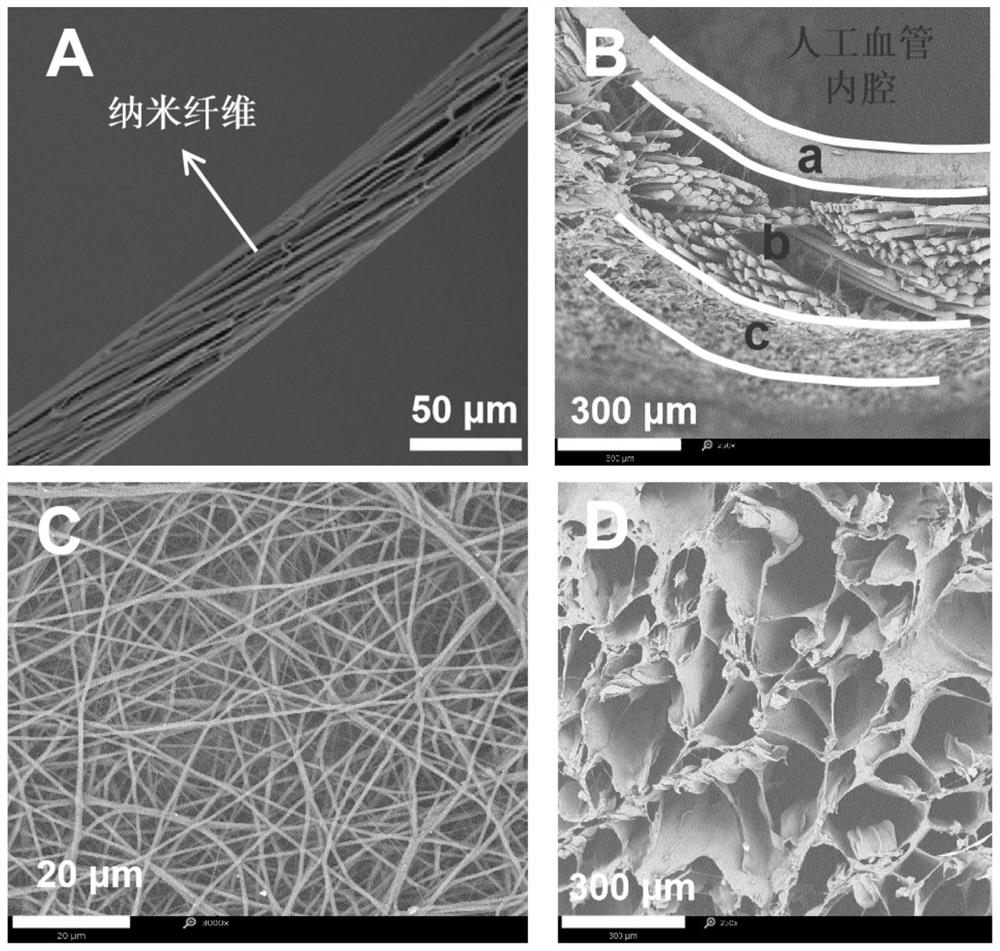

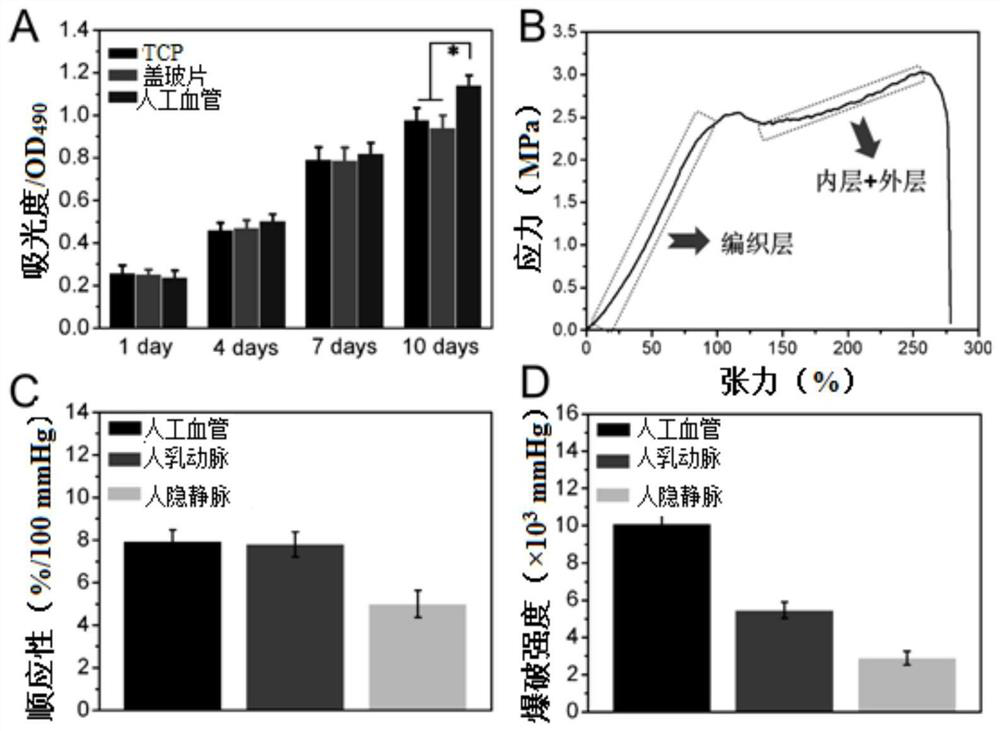

[0077] This embodiment provides a braided reinforced degradable polyurethane elastomer artificial blood vessel, refer to figure 1 and figure 2 , its preparation method comprises the following steps:

[0078] (1) Weaving PLGA / silk fibroin nanofiber yarns (the mass ratio of PLGA and silk fibroin is 1:1) (12 filaments with a single filament diameter of 10 μm) into a tubular braid;

[0079] (2) Spin PEO nanofibers with a thickness of about 5 μm on the 316L stainless steel with a diameter of 2 mm by electrospinning technology; continue to spin C-PEEUU-NH with a thickness of 100 μm on the fiber 2 nanofibers; link the above with PEO, C-PEEUU-NH 2 The 316L stainless steel with nanofibers was demoulded in ultrapure water; the C-PEEUU-NH 2 Continue to stir and wash the nanofiber tubular scaffold in ultra-pure water for 30 minutes to remove impurities on the surface of the fiber, then vacuum freeze-dry and set aside;

[0080] (3) The prepared C-PEEUU-NH 2 The nanofiber tubular scaf...

Embodiment 2

[0085] This embodiment provides a braided reinforced degradable polyurethane elastomer artificial blood vessel, refer to figure 1 and image 3 , its preparation method comprises the following steps:

[0086] (1) PLGA / PDO / PGA / silk fibroin nanofiber yarn (PLGA / PDO / PGA total mass and silk fibroin mass ratio is 4:1, wherein PLGA, PDO and PGA in PLGA / PDO / PGA total mass The mass ratio is 1:1:1) (a total of 12 single filaments with a diameter of 10 μm) are woven into tubular braids;

[0087] (2) Spin PEO nanofibers with a thickness of about 5 μm on the 316L stainless steel with a diameter of 2 mm by electrospinning technology; continue to spin C-PEEUU-NH with a thickness of 100 μm on the fiber 2 nanofibers; link the above with PEO, C-PEEUU-NH 2 The 316L stainless steel with nanofibers was demoulded in ultrapure water; the C-PEEUU-NH 2 Continue to stir and wash the nanofiber tubular scaffold in ultra-pure water for 30 minutes to remove impurities on the surface of the fiber, then va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com