Method for synergistically pretreating TDI production wastewater by using chemical wastes

A technology for producing wastewater and pretreatment, which is applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc. It can solve the problems of difficulty in purification, high treatment costs, and high sludge disposal costs, and achieves reduction of COD value and reaction. Mild conditions and improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

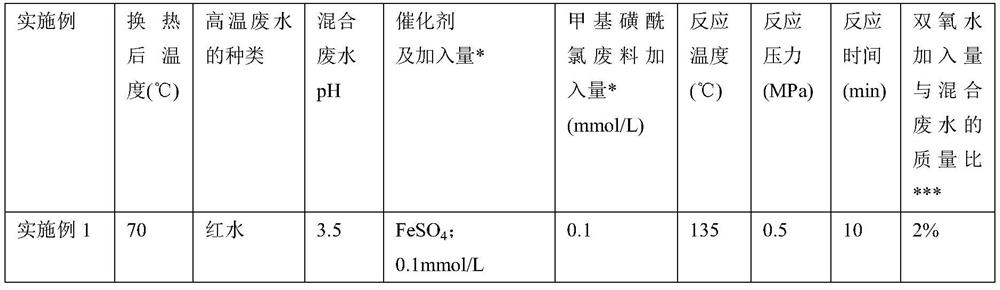

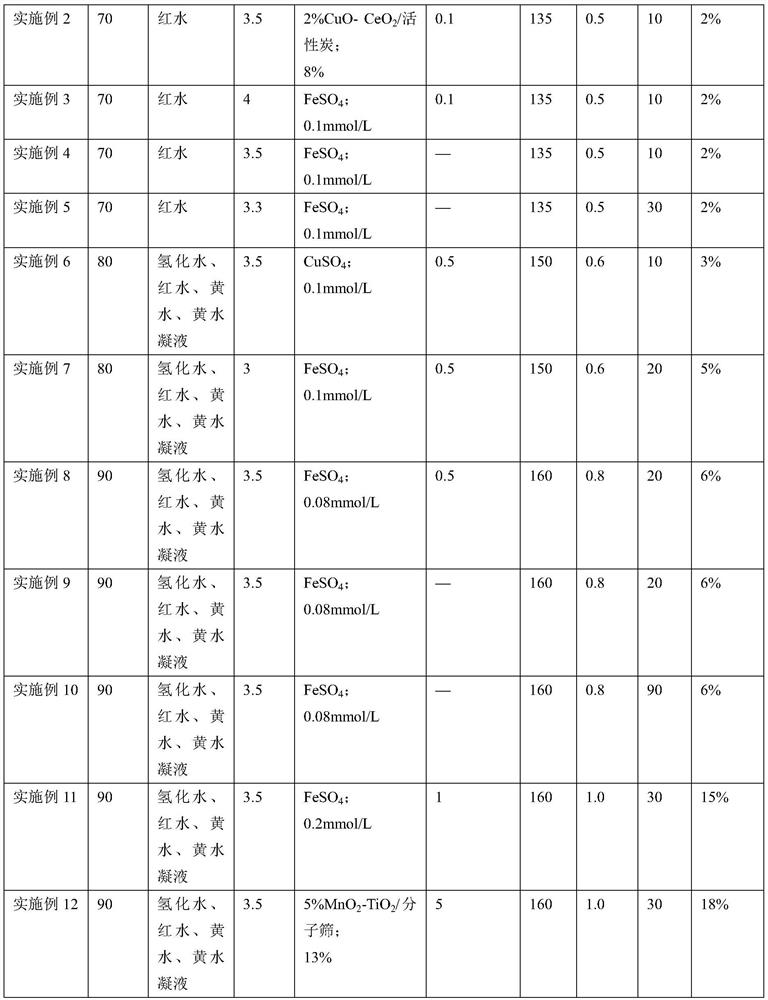

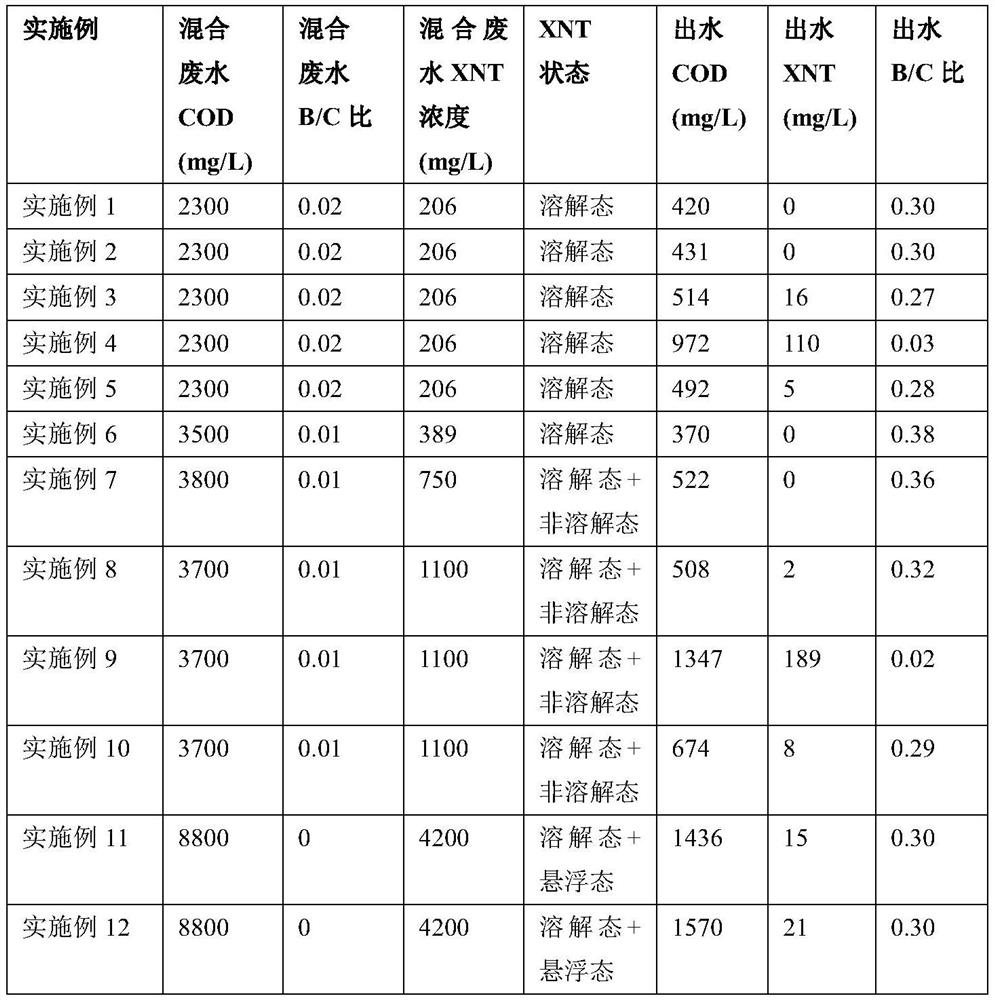

Embodiment 1-12

[0054] (1) Heat up the hydrogenated wastewater and acidic wastewater by heat exchange; before the system runs, the temperature is raised to 70-100°C by means of external heating, and when the system is continuously processed after the system is running, the mixed wastewater enters the closed heat exchange system through heat exchange, and is subsequently discharged from the autoclave as a heat exchange medium;

[0055] The hydrogenation waste water is mainly flushing waste water in the hydrogenation unit area in TDI production; the acid waste water is the steamed water from the waste acid concentration device and / or the maintenance effluent from the nitrification unit in the TDI production;

[0056] Among them, the amount of hydrogenation wastewater and acid wastewater is mixed according to the actual production process at any time, and the mass ratio of the two in this embodiment is 1:1.5-2.5. .

[0057] (2) Mixing one or more high-temperature wastewaters of hydrogenated wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com