Rumen bypass product and production method thereof

A production method and rumen-passing technology, which are applied in the production field of preparing rumen-passing series products, can solve the problems of less release of amino acids, low apparent biological titer of methionine, uneven particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

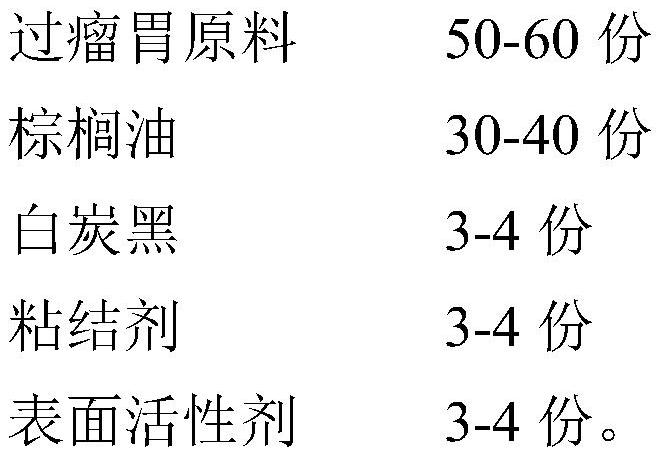

[0026] Raw material composition of rumen-passed products: (take rumen-passed methionine as an example):

[0027]

[0028] Methods of producing rumen-passed products:

[0029] Raw material pretreatment: sieve the methionine core-coated raw material with a mesh number of 80 mesh;

[0030] Pretreatment of excipients: put palm oil in the reaction kettle for heating and melting, control the temperature while stirring, keep the temperature at 80°C until the palm oil is stirred evenly and the temperature is stable, then add surfactant Tween 80 for mixing Uniform, ready to use;

[0031] Raw material granulation: Add white carbon black adsorption liquid and binder dextrin to the crushed and sieved raw materials for granulation and spheronization;

[0032] Bottom spraying operation: Put the dried material into the fluidized bed coating machine, turn on the steam heating, extract the palm oil in the reactor and coat the material through the bottom spraying system until all spraying ...

Embodiment 2

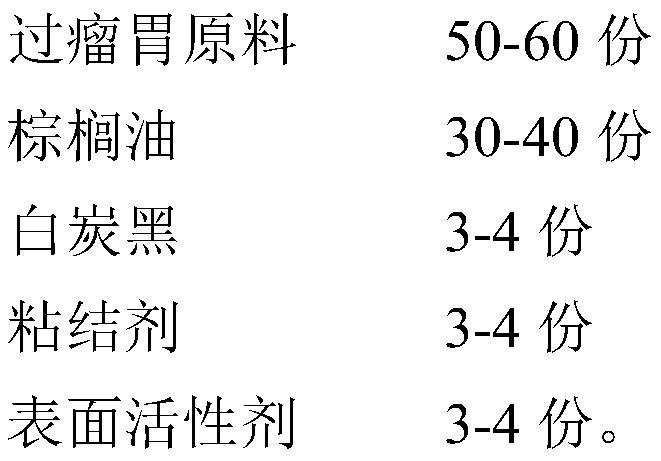

[0034] Raw material composition of rumen-passed products (taking rumen-passed choline chloride as an example):

[0035]

[0036] Methods of producing rumen-passed products:

[0037] Raw material pretreatment: sieve the choline chloride raw material, the sieve mesh number is 160 mesh;

[0038] Pretreatment of excipients: put palm oil into the reaction kettle for heating and melting, control the temperature while stirring, keep the temperature at 90°C until the palm oil is stirred evenly and the temperature is stable, then add the surfactant fatty acid sorbitan for mixing Uniform, ready to use;

[0039] Raw material granulation: add white carbon black adsorption liquid and binder to the crushed and sieved raw materials for granulation and spheronization;

[0040] Bottom spraying operation: Put the dried material into the fluidized bed coating machine, turn on the steam heating, extract the hydrogenated vegetable oil in the reactor and coat the material through the bottom sp...

Embodiment 3

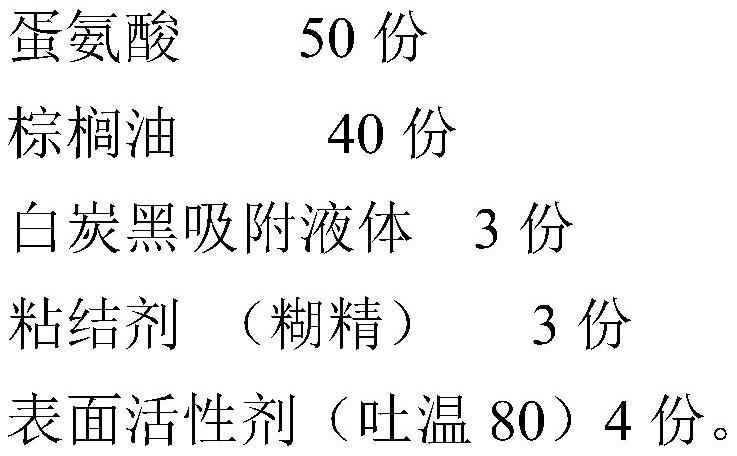

[0042] Raw material composition of rumen-passed products (taking rumen-passed lysine as an example):

[0043]

[0044] Methods of producing rumen-passed products:

[0045] Raw material pretreatment: sieve the lysine raw material with a mesh size of 150 mesh;

[0046] Pretreatment of excipients: put palm oil into the reaction kettle for heating and melting, control the temperature while stirring, keep the temperature at 85°C until the palm oil is stirred evenly and the temperature is stable, then add surfactant Tween 80 for mixing Uniform, ready to use;

[0047] Raw material granulation: Add white carbon black adsorption liquid and binder vinyl acetate resin to the crushed and sieved raw materials for granulation and spheronization;

[0048] Bottom spraying operation: Put the dried material into the fluidized bed coating machine, turn on the steam heating, extract the palm oil in the reactor and coat the material through the bottom spraying system until all spraying is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com