Preparation method of polyhedral transition metal carbide particles for catalytic material

A technology of carbide particles and transition metals, which is applied in the field of preparation of polyhedral transition metal carbide particles, can solve the problem that particle size, morphology and specific crystal plane cannot be well controlled, and transition metal carbides cannot achieve large-scale controllable preparation , the preparation process cannot be controlled, etc., to achieve the effect of regular shape, uniform size and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing polyhedral transition metal carbide particles for catalytic materials, comprising the following steps:

[0040] Step 1. Mix aluminum powder, transition metal powder and carbon source evenly in a ball mill, the mass ratio of ball to material in the ball mill is 5:1-20:1, the speed of the ball mill is 50-100r / min, and the ball milling time is 8-24h; The evenly mixed powder is taken out and wrapped in aluminum foil, and pressed into a cylindrical preparation block, and then placed in a graphite grinding tool;

[0041] Wherein, the transition metal powder includes titanium powder, tantalum powder, niobium powder, zirconium powder, tungsten powder and or vanadium powder; the carbon source is carbon black or CNTs.

[0042] The content of the aluminum powder is 40-70wt.%, the molar ratio of the carbon source to the transition metal powder is 0.5-0.8; the purity of the aluminum powder is greater than 99.9%, and the purity of the tra...

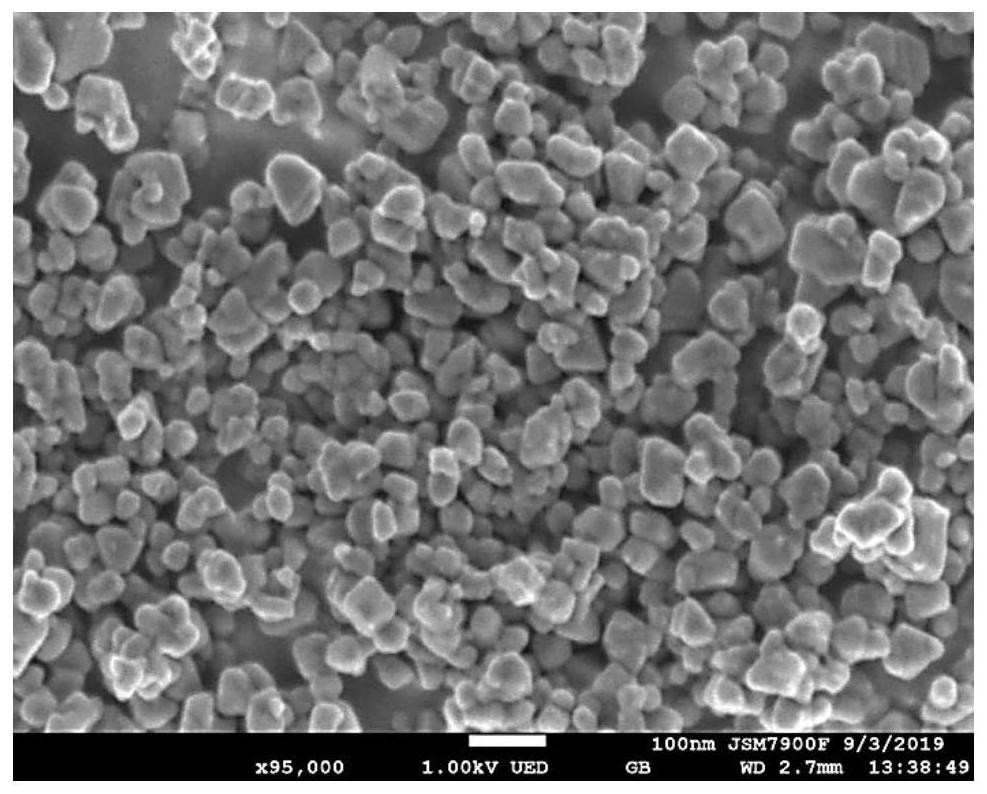

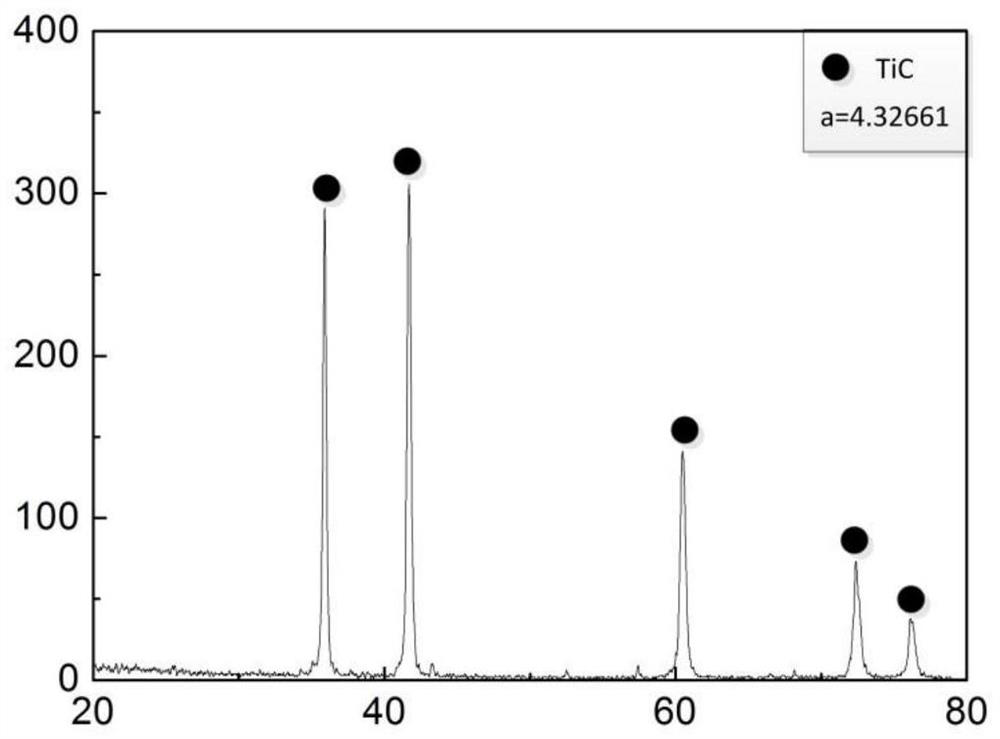

Embodiment 1

[0050] Preparation of nano-polyhedral TiC particles with uniform size and regular shape at low temperature: First, weigh Al powder (purity ≥ 99.9%), Ti powder (purity ≥ 99.9%) and CNTs, wherein the Al content is 40wt.%, C / Ti The molar ratio is 0.6, the weighed powder is poured into a ball mill tank, and mixed by a ball mill, wherein the ball mass ratio in the ball mill tank is 15:1, the ball mill speed is 50r / min, and the ball mill time is 24h.

[0051] Then, sieve the uniformly mixed powder from the ball mill jar, weigh 30g of the uniformly mixed powder and wrap it with aluminum foil, and use a metal compressor to press it in a self-made grinding tool to form a cylindrical block with a diameter of 30mm and a height of 10mm.

[0052] After that, put the pressed cylindrical block into a self-made graphite mold, put them together into a vacuum hot-pressing sintering furnace, and start heating after the vacuum is exhausted, wherein the vacuum degree is kept below 10Pa, and the hea...

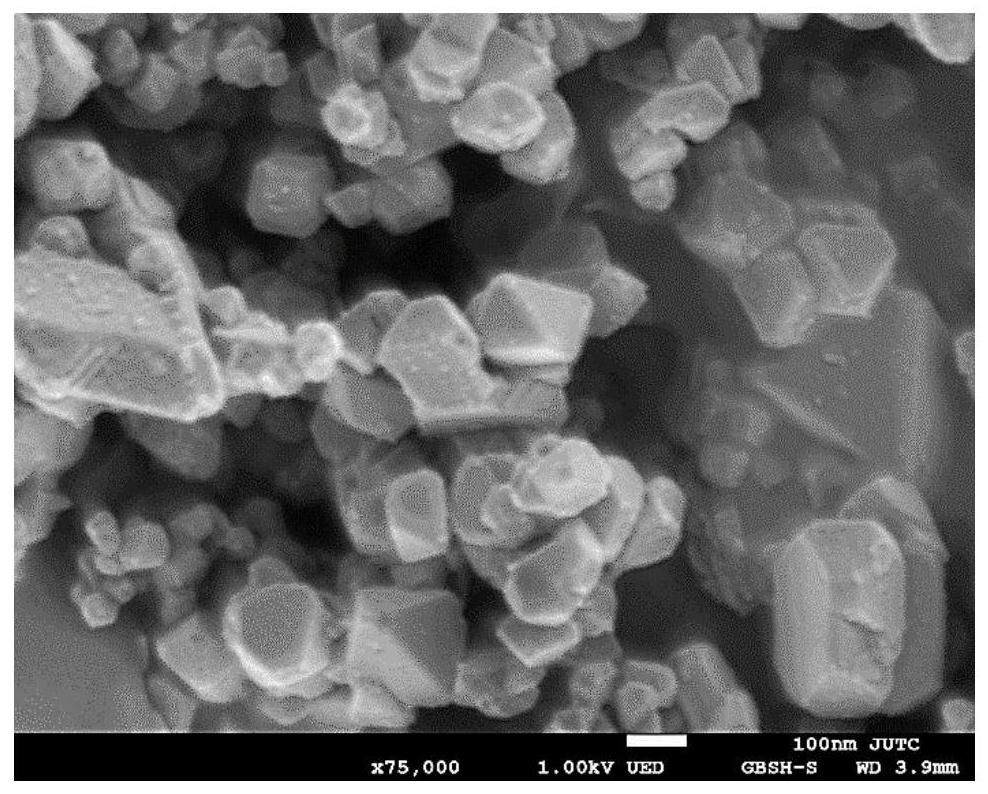

Embodiment 2

[0055] Preparation of nano-polyhedral TiC particles with uniform size and regular shape at low temperature: first, weigh Al powder (purity ≥ 99.9%), Ti powder (purity ≥ 99.9%) and CNTs, wherein the Al content is 60wt.%, C / Ti The molar ratio is 0.6, the weighed powder is poured into a ball mill tank, and mixed by a ball mill, wherein the ball mass ratio in the ball mill tank is 15:1, the ball mill speed is 50r / min, and the ball mill time is 24h.

[0056] Then, sieve the uniformly mixed powder from the ball mill jar, weigh 30g of the uniformly mixed powder and wrap it with aluminum foil, and use a metal compressor to press it in a self-made grinding tool to form a cylindrical block with a diameter of 30mm and a height of 10mm.

[0057] After that, put the pressed cylindrical block into a self-made graphite mold, put them together into a vacuum hot-pressing sintering furnace, and start heating after the vacuum is exhausted, wherein the vacuum degree is kept below 10Pa, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com