A kind of bioelectrochemical reaction device and gas purification method

A chemical reaction and bioelectric technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of increasing the structural complexity and operating cost of the gas purification system, and there is no hydrogen sulfide bioelectrochemical system, purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

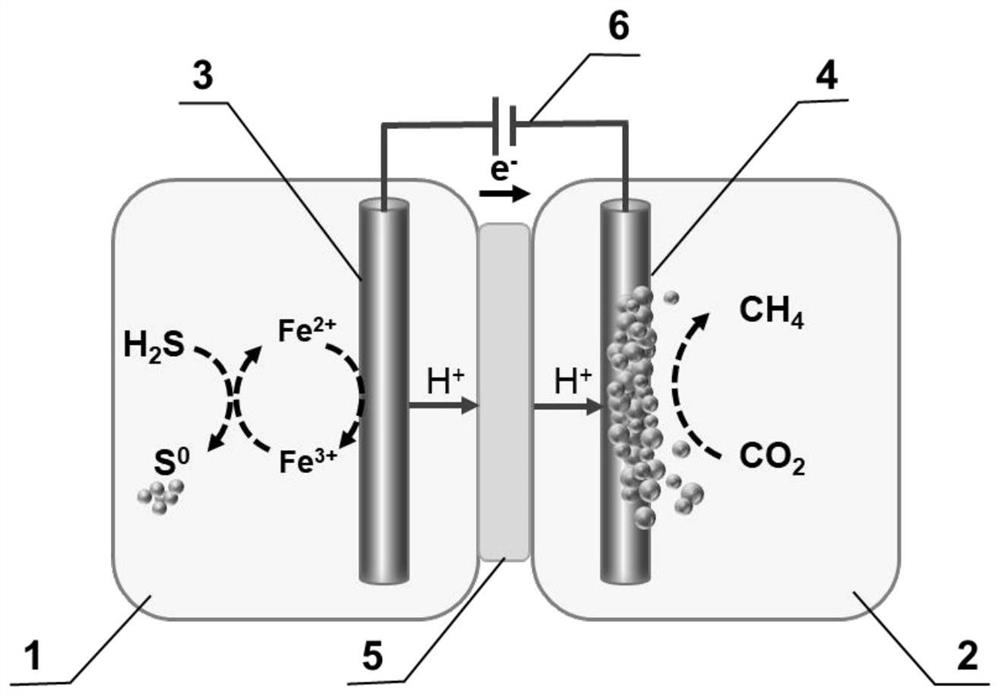

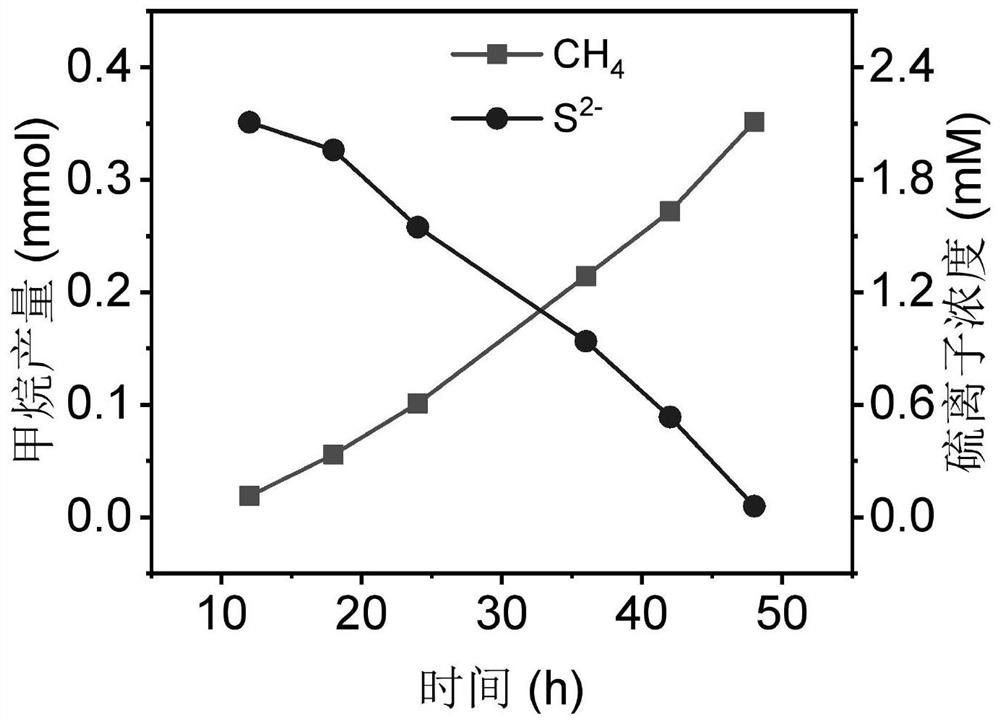

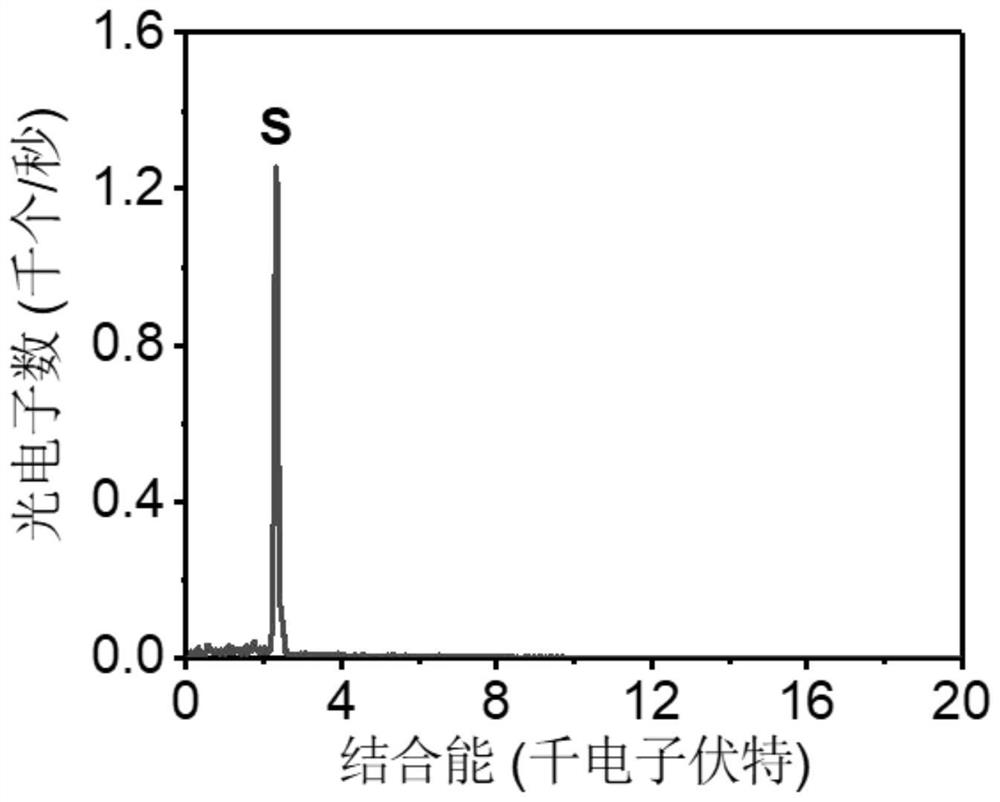

[0056] use figure 1 In the device shown, sodium sulfide is used instead of hydrogen sulfide as the sulfur source, and sodium bicarbonate in the culture medium and carbon dioxide in the headspace are used as the carbon source to perform simultaneous sulfur ion oxidation and recovery of elemental sulfur and carbon dioxide reduction to produce methane.

[0057] High-purity nitrogen (purity of 99.999%) and nitrogen / carbon dioxide mixture (the volume ratio of nitrogen and carbon dioxide in the mixture is 80:20) were used to fully aerate the headspace of the anode chamber and the cathode chamber, and then in the anode chamber Add described sulfur source (anolyte solution is ferrous sulfate solution, the concentration of ferrous sulfate solution is 0.2mol / L, the pH value of anolyte solution is 1.0), inoculate in the cathode chamber Hydrophilic methanogen (cultivated). The base solution is the standard DSMZ 141 medium obtained after removing zymosan, peptone and sodium acetate, the pH...

Embodiment 2

[0064] High-purity nitrogen gas and pure carbon dioxide gas (purity of 99.95%) were used to fully aerate the headspace of the anode and cathode chambers, respectively, and then 1% H 2 S(99%N 2 ) gas is continuously fed into the anode chamber at a rate of 1.0 mL / min (the anolyte is a ferrous sulfate solution, the concentration of the ferrous sulfate solution is 0.2 mol / L, and the pH of the anolyte is 1.0), and 0.1 M The sodium hydroxide solution is used as the exhaust gas absorption liquid; inoculate the hydrogenophilic methanogen in the cathode chamber (the medium solution is the standard DSMZ 141 medium after removing the zymoin, peptone and sodium acetate, the pH value of the medium solution is 8.0 ± 0.2, the final concentration of 100mM diglyceride is used as buffer salt in the medium solution), the circuit is connected, and the entire bioelectrochemical reaction device is placed at 37 V under the condition that the applied voltage ensures that the cathode potential is -0.7...

Embodiment 3

[0072] High-purity nitrogen and carbon dioxide / methane mixed gas (the volume ratio of carbon dioxide and methane in the mixed gas is 40:60) were used to fully aerate the headspace of the anode chamber and the cathode chamber, and then 1% H 2 S(99%N 2 ) gas is continuously fed into the anode chamber at a rate of 1.0 mL / min (the anolyte is a ferrous sulfate solution, the concentration of the ferrous sulfate solution is 0.2 mol / L, and the pH of the anolyte is 1.0), and 0.1 M The sodium hydroxide solution is used as the exhaust gas absorption liquid; inoculate the hydrogenophilic methanogen in the cathode chamber (the medium solution is the standard DSMZ 141 medium, the medium obtained after removing the yeast, peptone and sodium acetate, the pH value of the medium solution is 8.0 ± 0.2, using the final concentration of 100mM DDP in the medium solution as a buffer salt), connecting the circuit, and applying the voltage to ensure that the cathode potential is -0.7V, the entire bioe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com