Method for improving fractional separation and depolymerization of lignin of biomass and application of method

A technology for fractional separation and lignin, applied in the directions of lignin derivatives, chemical instruments and methods, ether preparation, etc., can solve problems such as commercial development limitations, ineffective implementation, etc., to achieve the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

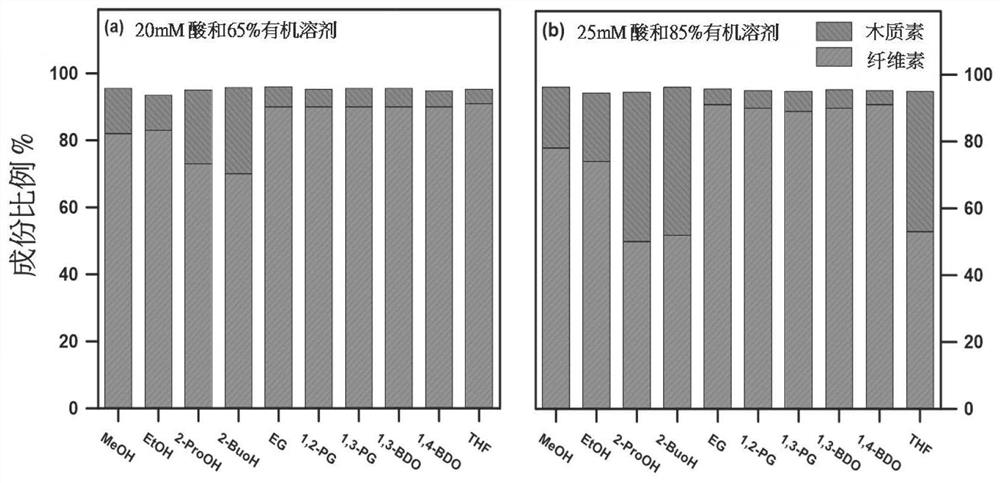

[0063] 1. Pretreatment of eucalyptus wood powder: eucalyptus wood chips are made into eucalyptus wood powder, eucalyptus wood powder is added in the pretreatment liquid (mixed solution of glycol and water), with sulfuric acid as catalyst, adopt rotary cooker (Xianyang Tongda Light Industry Equipment Co., Ltd.) pretreated the eucalyptus powder. Wherein, the dihydric alcohol is ethylene glycol (EG), 1,2-propanediol (1,2-PG), 1,3-propanediol (1,3-PG), 1,3-butanediol (1 ,3-BDO), 1,4-butanediol (1,4-BDO).

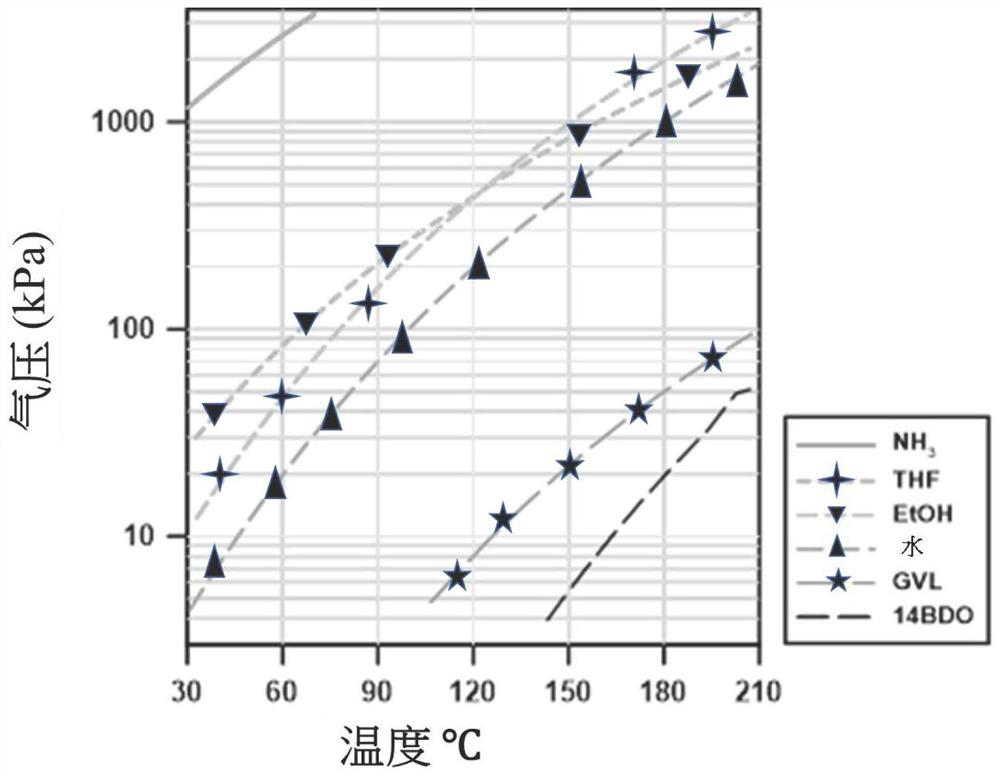

[0064]Mix 50g of eucalyptus powder with 20mmol / L sulfuric acid and pretreatment solution (volume ratio of glycol and water is 65%:35%), and mix with liquid (sulfuric acid and glycol) solid mass ratio as 7:1. The digester was heated to 167-173° C. for pretreatment at a rate of 3° C. / min, and kept at this temperature for 60 minutes. The specific experimental conditions of Examples 1-5 are shown in Table 1.

[0065] Glycol and solvent ratio in acid concentration, pretreatment sol...

Embodiment 6-10

[0070] 1. Pretreatment of eucalyptus wood powder: join eucalyptus wood powder in the pretreatment solution (mixed solution of glycol and water), use sulfuric acid as catalyst, adopt rotary cooker (Xianyang Tongda Light Industry Equipment Co., Ltd.) to treat eucalyptus Wood flour is pretreated. Wherein, the dihydric alcohol is ethylene glycol (EG), 1,2-propanediol (1,2-PG), 1,3-propanediol (1,3-PG), 1,3-butanediol (1 ,3-BDO), 1,4-butanediol (1,4-BDO).

[0071] Mix 50g of eucalyptus powder with 25mmol / L of sulfuric acid and pretreatment solution (the volume ratio of glycol and water is 85%:15%), and mix it with liquid (sulfuric acid and glycol) at a solid mass ratio of 7:1. The digester was heated to 167-173° C. for pretreatment at a rate of 3° C. / min, and kept at this temperature for 60 minutes. The specific experimental conditions of Examples 6-10 are shown in Table 2.

[0072] Concentration of acid, dibasic alcohol and its solvent ratio in the pretreatment solution in table...

Embodiment 11

[0077] The difference from Example 10 is that the acid concentration is 150mmol / L, the pretreatment temperature is 120°C, and the pretreatment time is 240min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com