A kind of amidated graphene airgel and its preparation method and application

A technology of carboxylated graphene and airgel, which is applied in the field of water treatment, can solve the problems of poor microbial affinity of graphene airgel materials, the graphene layer is easily exposed, and the purification effect cannot be achieved, and achieve strong heavy metal adsorption Performance and microbial affinity, beneficial to microbial attachment, and the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

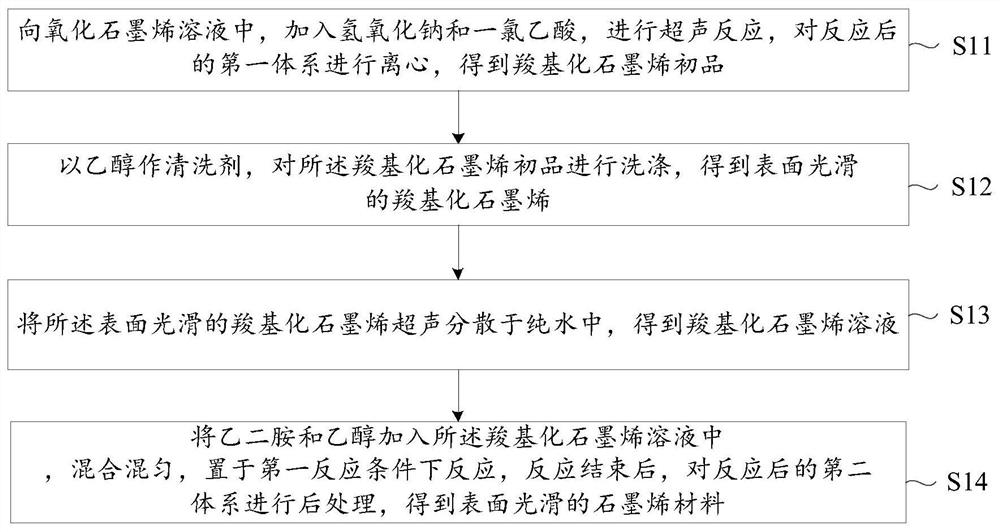

[0052] First aspect, the present invention provides a kind of preparation method of amidated graphene airgel, such as figure 1 As shown, during specific implementation, the method may include the following steps:

[0053] Step 1 (S11), adding sodium hydroxide and monochloroacetic acid to the graphene oxide solution, performing an ultrasonic reaction, and centrifuging the first system after the reaction to obtain a primary product of carboxylated graphene.

[0054] During specific implementation, graphene oxide is dissolved in pure water, sodium hydroxide and monochloroacetic acid are added, stirred evenly, and ultrasonically reacted for 10 to 15 hours. After the reaction was completed, high-speed centrifugation was carried out to obtain a brown-black solid (i.e., the primary product of carboxylated graphene).

[0055] In this implementation step, optionally, the concentration of the graphene oxide solution obtained after graphene oxide is dissolved in pure water can be 1 to 5...

Embodiment 1

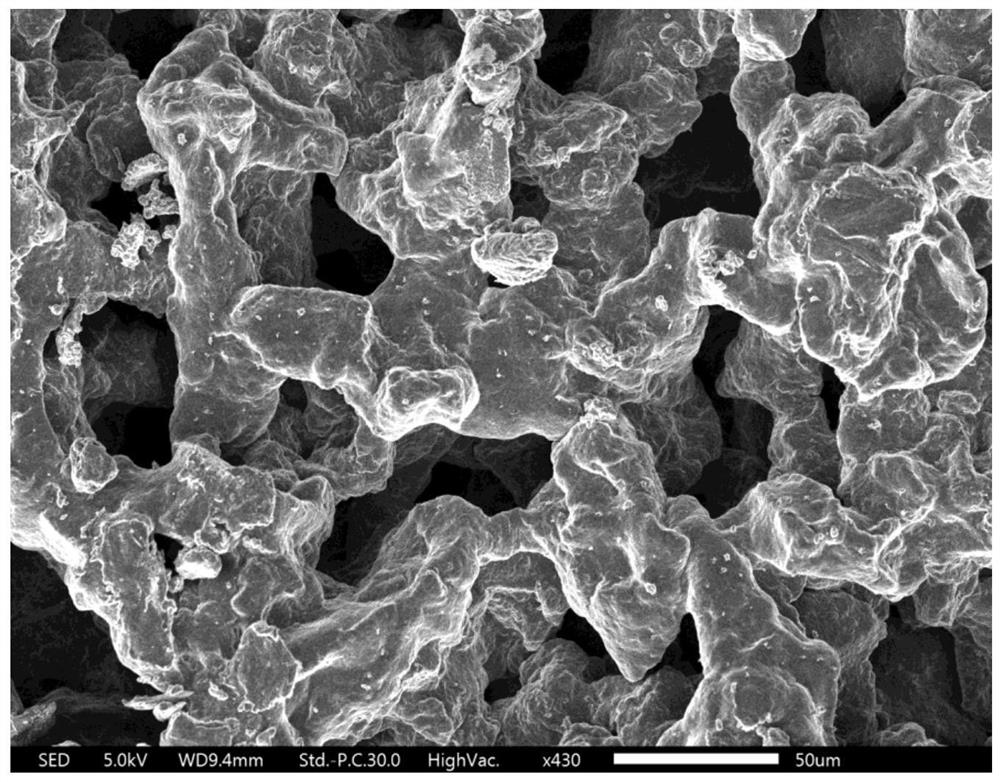

[0079] Embodiment 1: prepare amidated graphene airgel of the present invention

[0080] (1) Configure 200mL 9:1 sulfuric acid / phosphoric acid mixed solution in a beaker. Weigh 1.5g of graphite powder, pour it into the above mixed solution, and stir evenly. Cool the beaker containing the mixed solution in an ice-water bath and slowly add 9.0 g of potassium permanganate. At this time, ensure that the temperature of the mixed solution system does not exceed 20°C when adding potassium permanganate. After the potassium permanganate was added, the beaker containing the mixed solution was placed on a magnetic heating stirrer, the magnetic stirring speed was 300 rpm, and the temperature of the mixed solution in the beaker was kept at 50° C. for 12 hours. After the reaction was completed, the mixed solution was cooled to room temperature, and then the solution was mixed with 200 ml of ice and placed in an ice-water bath. Slowly drop 0.5% hydrogen peroxide solution into the mixed solu...

Embodiment 2

[0085] The preparation process of amidated graphene airgel is the same as that of Example 1.

[0086] Cu on the prepared amidated graphene airgel 2+ Heavy metal adsorption experiments. Configure 200mg / L Cu(NO) 2 Solution 50mL. A certain mass of amidated graphene airgel was weighed and added to the above solution, and the mixed system was shaken in a water bath shaker at 30°C. Take 2mL solution every 1 hour to measure the Cu in it 2+ concentration until Cu 2+ Concentration no longer changes. Finally, according to the equilibrium concentration, the amidated graphene airgel pair Cu 2+ the equilibrium adsorption capacity. Experimental results such as Figure 5 As shown, the adsorption of Cu 2 + In the case of the same initial Cu 2+ The equilibrium adsorption capacity of the amidated graphene aerogel at the concentration is about 85% higher than that of the traditional reduction method graphene aerogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com