Super-hydrophobic anticorrosive paint and preparation method thereof

An anti-corrosion coating and super-hydrophobic technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor hydrophobicity and durability of anti-corrosion coatings, and achieve the effects of high cost performance, rapid drying, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to another aspect of the present invention, provide the preparation method of superhydrophobic anticorrosion coating, comprise the following steps:

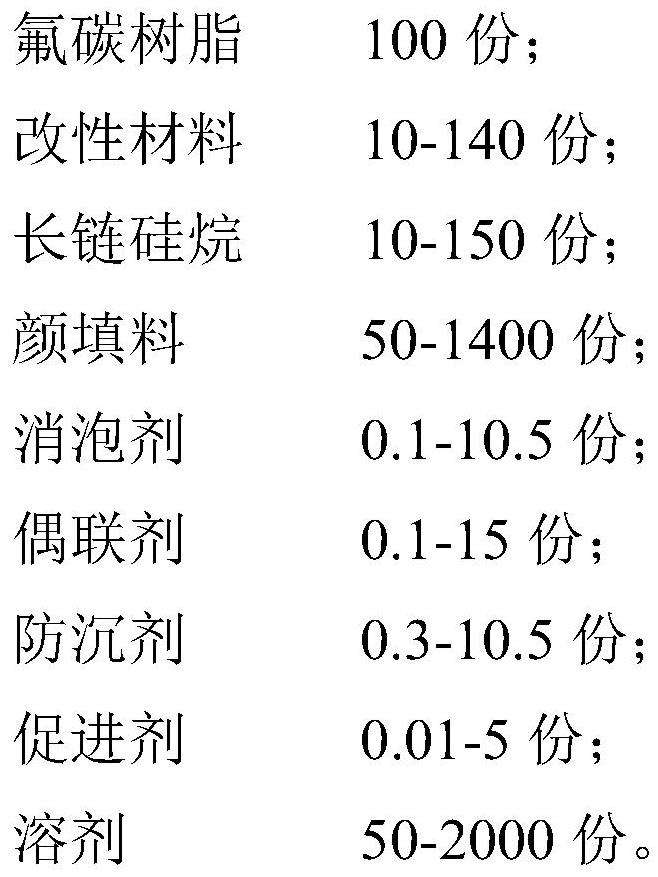

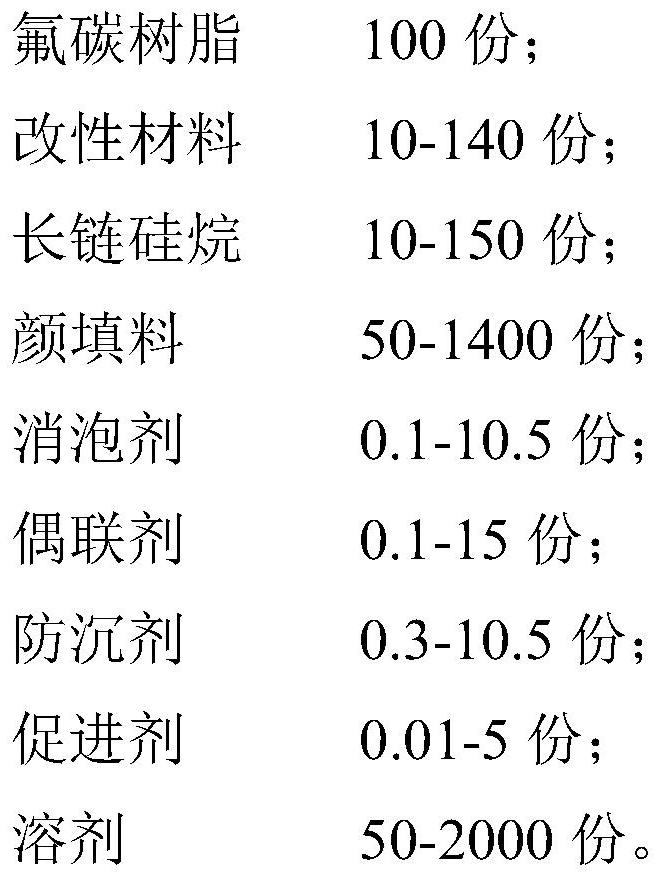

[0050] S1. Weighing the raw materials according to the weight ratio:

[0051] 100 parts of fluorocarbon resin; 10-140 parts of modified material; 10-150 parts of long-chain silane; 50-1400 parts of pigment and filler; 0.1-10.5 parts of defoamer; 10.5 parts; Accelerator 0.01-5 parts; Solvent 50-2000 parts;

[0052] S2. In the range of -5°C to 30°C, pour the solvent into the dissolution tank, and add long-chain silane while stirring;

[0053] S3, adding pigments and fillers and modified materials, stirring evenly;

[0054] S4, slowly add accelerator, stir for 15-60 minutes;

[0055] S5, add fluorocarbon resin and defoamer, stir until uniform; wherein, the stirring speed is 400-1500 r / min;

[0056] S6, after being ground by a sand mill to a fineness of less than 200 μm;

[0057] S7. Add anti-sedimentation agent...

Embodiment 1

[0060] S1, the proportioning by weight of raw materials is as follows: the solvent is 10 parts of xylene, 10 parts of butyl acetate, and 70 parts of ethylene glycol ether acetate; the long-chain silane is 5 parts of hexadecyltrimethoxysilane, and 5 parts of fluorodecyltriethoxysilane; the modified material is 5 parts of xylene formaldehyde resin, 5 parts of dimethyl phthalate; the pigment and filler are 10 parts of talcum powder, 10 parts of mica, and 30 parts of barium sulfate; The agent is 0.01 part of acetic acid; 100 parts of fluorocarbon resin; the defoaming agent is 0.1 part of dimethyl silicone oil solution; the coupling agent is 0.5 part of titanate coupling agent; the anti-settling agent is 0.3 part of fumed silica;

[0061] S2. In the range of -5°C to 30°C, pour the solvent into the dissolving tank, and add hexadecyltrimethoxysilane while stirring;

[0062] S3, adding 10 parts of talcum powder, 10 parts of mica and 30 parts of barium sulfate and pigments and fillers ...

Embodiment 2

[0068] The proportioning by weight of raw material is:

[0069] The solvent is 500 parts of ethylene glycol ether, 500 parts of ethylene glycol butyl ether, 500 parts of ethylene glycol ether acetate, and 500 parts of dimethyl carbonate; the long-chain silane is 150 parts of hexadecyl dimethyl chlorosilane; The active material is 50 parts of dimethyl phthalate, 50 parts of dibutyl phthalate, 50 parts of silica sol; the pigment and filler are 100 parts of barite powder, 100 parts of silica powder, 100 parts of wollastonite, heavy calcium 100 parts, light calcium 100 parts, quartz powder 100 parts, lithopone 100 parts, kaolin 100 parts, titanium dioxide 100 parts, chrome yellow 100 parts, chrome red 100 parts, chrome green 100 parts, zinc oxide 100 parts, carbon black 100 parts; accelerator is 0.01 parts of hydrochloric acid, 4.99 parts of water; 100 parts of fluorocarbon resin; defoamer is 10.5 parts of polysiloxane solution; coupling agent is 15 parts of silane coupling agent;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com