Corrosion-resistant antibacterial antistatic coating and preparation method thereof

An anti-static and corrosion-resistant technology, used in anti-corrosion coatings, conductive coatings, anti-fouling/underwater coatings, etc. The effect of good adhesion, filling the market gap and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

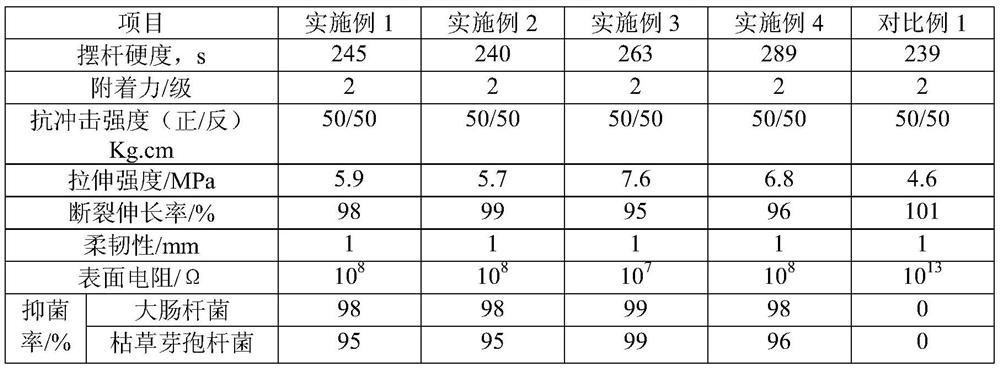

Examples

Embodiment 1

[0033] (1) Preparation of hydroxyacrylate emulsion

[0034] A. Preparation:

[0035] Weigh methyl methacrylate, butyl acrylate, acrylic acid and hydroxyethyl methacrylate in a weight ratio of 10:14:1:8 and put them into a beaker as a mixed monomer for use.

[0036] B, preparation of seed emulsion:

[0037] Add 40 parts by weight of distilled water, 0.8 parts by weight of emulsifier SDS / OP-10 (weight ratio 4:6) and 0.1 parts by weight of Sodium bicarbonate, vacuumize and fill with nitrogen, control the reaction temperature at 85°C; add 5% of the total amount of mixed monomers, and start to drop 0.05 parts by weight of initiator ammonium persulfate at a speed of 0.05mL / min at the same time. for 30 minutes until a uniform blue phase appears in the system.

[0038] C. Polymerization reaction:

[0039] Add the remaining mixed monomer and 0.15 parts by weight of the initiator ammonium persulfate at 85°C. The dropping time is 2.5 hours. 95 to adjust the pH value to 9 to obtain a...

Embodiment 2

[0045] (1) Preparation of hydroxyacrylate emulsion

[0046] A. Preparation:

[0047] Weigh methyl methacrylate, butyl acrylate, acrylic acid and hydroxyethyl methacrylate in a weight ratio of 10:14:1:8 and put them into a beaker as a mixed monomer for use.

[0048] B, preparation of seed emulsion:

[0049] Add 40 parts by weight of distilled water, 1.2 parts by weight of emulsifier SDS / AEO-9 (weight ratio 5:5) and 0.1 parts by weight of Sodium bicarbonate was evacuated and filled with nitrogen, and the reaction temperature was controlled at 75°C. Add 5% of the total amount of mixed monomers, and at the same time start to drop 0.05 parts by weight of initiator ammonium persulfate at a rate of 0.05 mL / min. The reaction time is 30 minutes, and a uniform blue phase appears in the system.

[0050] C. Polymerization reaction:

[0051] Add the remaining mixed monomers and 0.15 parts by weight of the initiator ammonium persulfate at 80°C. The dropping time is 2.5 hours. After the ...

Embodiment 3

[0057] (1) Preparation of hydroxyacrylate emulsion

[0058] A. Preparation:

[0059] Weigh methyl methacrylate, butyl acrylate, acrylic acid and hydroxyethyl methacrylate in a weight ratio of 10:14:1:8 and put them into a beaker as a mixed monomer for use.

[0060] B, preparation of seed emulsion:

[0061] Add 40 parts by weight of distilled water, 1.0 parts by weight of emulsifier BL673 and 0.1 parts by weight of sodium bicarbonate in a four-necked flask equipped with an electric stirrer, a thermometer, a condenser tube and a dropping funnel, vacuumize and fill with nitrogen, and put the reaction The temperature was controlled at 85°C. Add 5% of the total amount of mixed monomers, and at the same time start to drop 0.05 parts by weight of initiator potassium persulfate at a rate of 0.05 mL / min. The reaction time is 30 minutes, and a uniform blue phase appears in the system.

[0062] C. Polymerization reaction

[0063] Add the remaining mixed monomers and 0.15 parts by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com