Cobalt-doped high-pressure cobalt-iron separation method for high-concentration cobalt-iron leaching solution

A separation method and leachate technology, applied in the field of hydrometallurgy, can solve the problems of increasing the pressure of subsequent wastewater treatment, reducing the iron grade of iron removal slag, high sulfur content, etc., reaching the limit of improvement and iron removal efficiency, increasing the gas-liquid contact area, The effect of improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

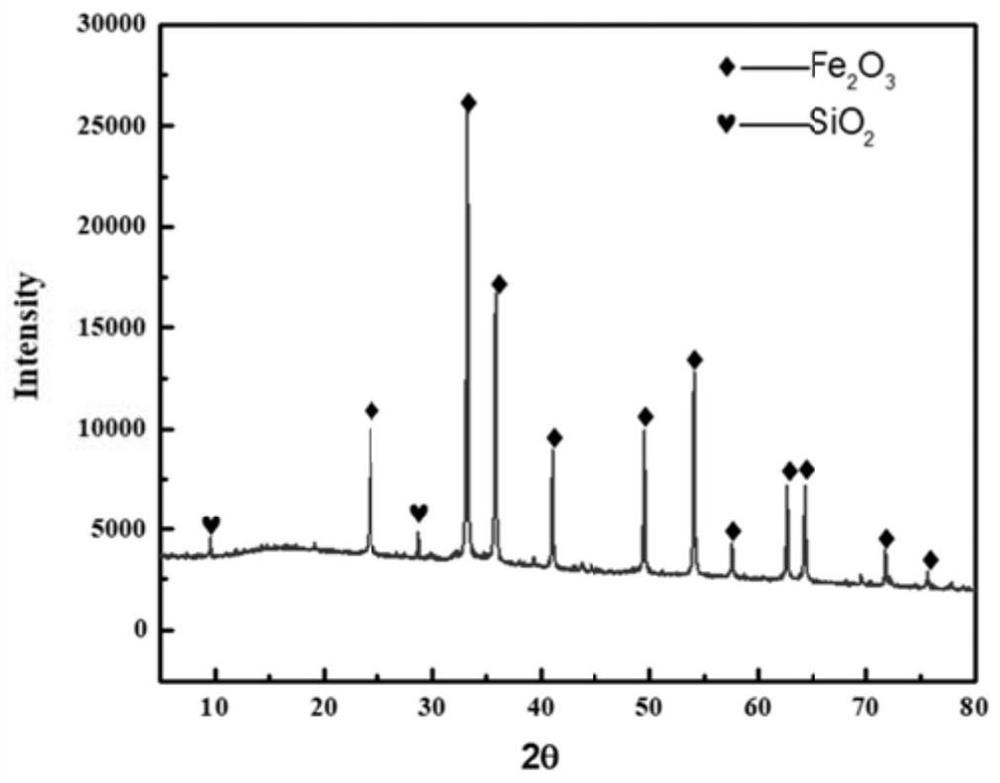

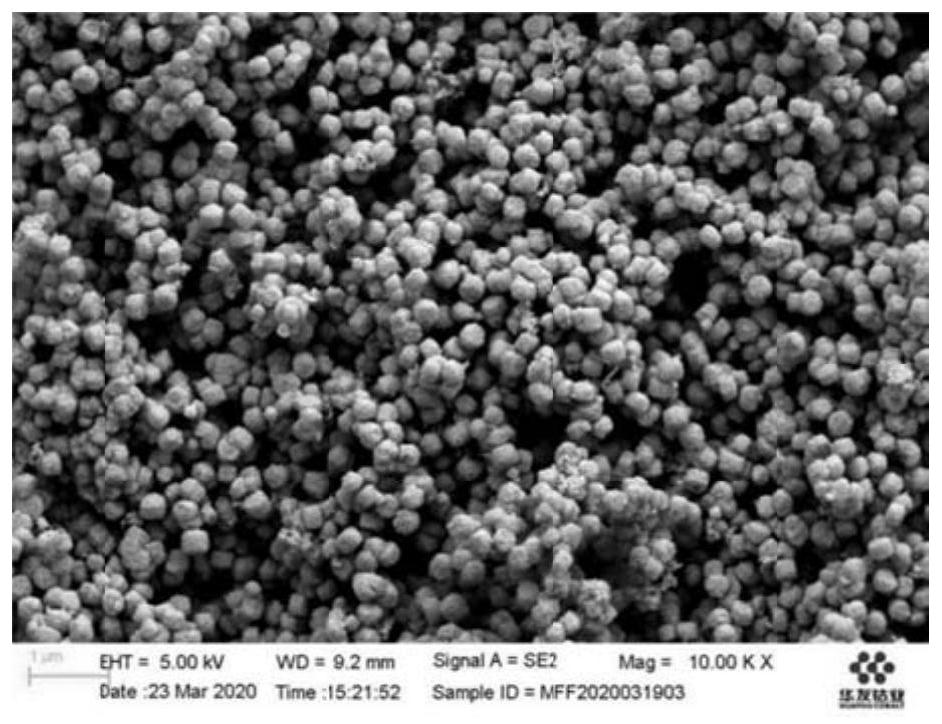

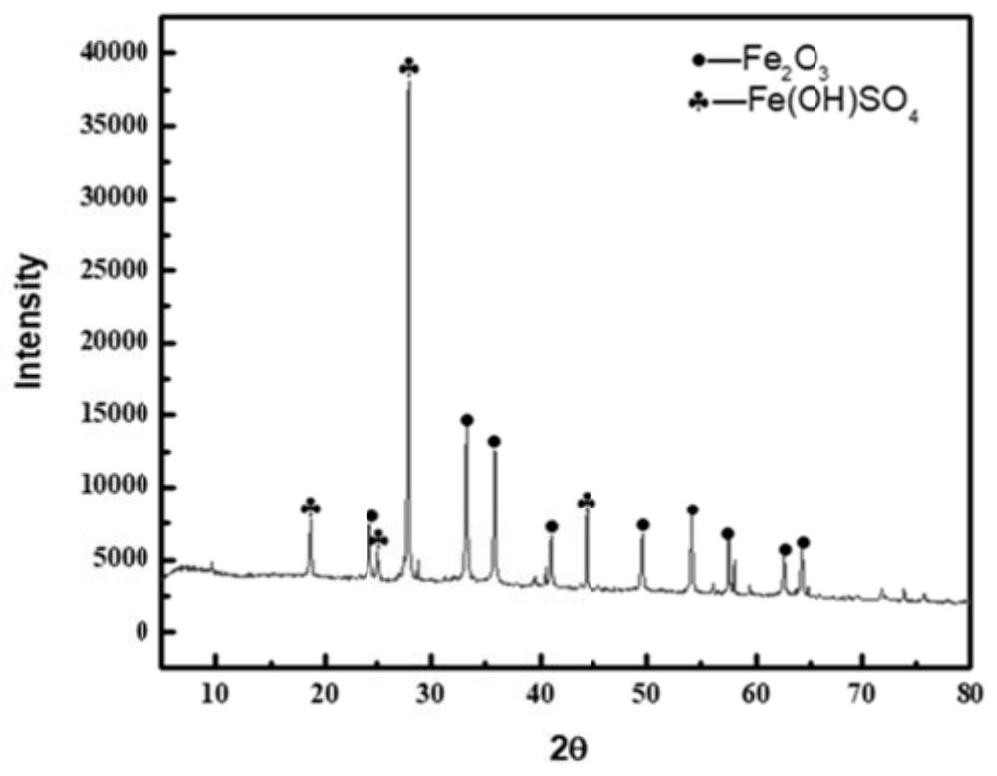

Embodiment 1

[0036] A cobalt-copper-iron alloy material was leached with sulfuric acid at 80°C to obtain a high-concentration leaching solution containing 103g / L of iron and 18g / L of cobalt. The solution was diluted to 1.6 times the volume after removing iron to obtain 65g / L of iron and 32g of cobalt. / L diluted solution, add Co(OH) at a concentration of 50g / L 2 Separation accelerator, the addition amount is 27.8g / L. The cobalt-iron pre-separation solution with a pH of 4.36 was obtained. It is continuously pumped into a closed high-pressure equipment, and the reaction is carried out under the environment of 180 ° C and 0.3MPa oxygen partial pressure, and the liquid flux rate is controlled to make the solution flow and react in the high-pressure equipment for about 2 hours. The pressure relief device relieves the pressure, and the generated steam heat resource is returned to the front end to maintain the liquid temperature before iron removal. After depressurization, the iron-removal liqu...

Embodiment 2

[0041] A cobalt-copper-iron alloy material was leached with sulfuric acid at 80°C to obtain a leaching solution containing 75g / L of iron and 15g / L of cobalt. The solution was diluted to 1.5 times the volume by separating the cobalt and iron to obtain 50.6g / L of iron and 21g of cobalt. / L diluted solution, add Co(OH) at a concentration of 30g / L 2 The iron removal accelerator was added in an amount of 11.2g / L. A solution before iron removal with pH of 3.5 was obtained. It is continuously pumped into a closed high-pressure equipment, and the reaction is carried out under the environment of 180 ° C and 0.3MPa oxygen partial pressure, and the liquid flux rate is controlled to make the solution flow and react in the high-pressure equipment for about 4 hours. The pressure of the device is relieved, and the generated steam heat resource is returned to the front end to maintain the liquid temperature before iron removal. The cobalt-iron separation liquid after pressure relief enters ...

Embodiment 3

[0043] A cobalt-copper-iron alloy material was leached with sulfuric acid at 80 °C to obtain a high-concentration leaching solution containing 103 g / L of iron and 18 g / L of cobalt. Cobalt 32.5g / L diluted solution, add CoCO at a concentration of 50g / L 3 The iron removal accelerator was added in an amount of 41.5g / L. A solution before iron removal with pH 4.0 was obtained. It is continuously pumped into a closed high-pressure equipment, and the reaction is carried out under the environment of 180 ° C and 0.3MPa oxygen partial pressure, and the liquid flux rate is controlled to make the solution flow and react in the high-pressure equipment for about 2 hours. The pressure of the device is relieved, and the generated steam heat resource is returned to the front end to maintain the liquid temperature before iron removal. The cobalt-iron separation liquid after pressure relief enters the thickener at 80°C. After flocculation and sedimentation, the supernatant liquid is separated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com