High-activity tea carbon fiber for shoe material and preparation method of high-activity tea carbon fiber

A high-activity, tea charcoal technology, applied in the field of textile production, can solve the problems of limited antibacterial properties of tea charcoal materials, unspecified classification, poor antibacterial and antibacterial activities, etc., to achieve excellent antibacterial and deodorant performance, and avoid decomposition. Loss, excellent antibacterial and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

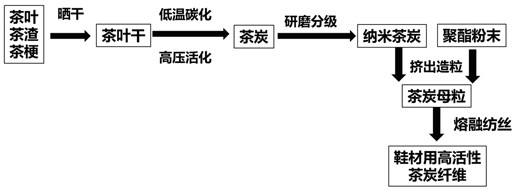

[0031] A kind of preparation method of highly active tea charcoal fiber for shoe material, its concrete steps are:

[0032] The first step: pretreatment of tea charcoal

[0033] Using tea leaves, tea dregs and tea stalks from agricultural and forestry wastes as raw materials, the raw materials are first washed and soaked in hot water at 60-80°C for 6 hours, and then dried in the sun at room temperature to obtain dried tea leaves, and then anaerobic Fermentation, so that the moisture content in the dry tea leaves is 1000ppm to obtain pretreated tea charcoal;

[0034] The second step: the preparation of tea charcoal

[0035] Use the pretreated tea charcoal prepared in step 1 as raw material, and then carry out low-temperature carbonization at 180-250°C for 6 hours in a nitrogen protective gas; then transfer to a high-pressure activation reactor for high-pressure activation reaction, using water as the medium, using Supercritical reaction conditions, the pressure in the high-pr...

Embodiment 2

[0048] A kind of preparation method of highly active tea charcoal fiber for shoe material, its concrete steps are:

[0049] The first step: pretreatment of tea charcoal

[0050] Using tea leaves, tea dregs and tea stems from agricultural and forestry wastes as raw materials, the raw materials are first washed and soaked in hot water at 60-80°C for 12 hours, and then dried in the sun at room temperature to obtain dried tea leaves, and then anaerobic Fermentation, so that the moisture content in the dry tea leaves is 5000ppm to obtain pretreated tea charcoal;

[0051] The second step: the preparation of tea charcoal

[0052] Use the pretreated tea charcoal prepared in step 1 as raw material, and then carry out low-temperature carbonization at 180-250°C for 8 hours in a nitrogen protective gas; then transfer to a high-pressure activation reactor for high-pressure activation reaction, using water as the medium, using Supercritical reaction conditions, control the pressure in the...

Embodiment 3

[0065] A kind of preparation method of highly active tea charcoal fiber for shoe material, its concrete steps are:

[0066] The first step: pretreatment of tea charcoal

[0067] Using tea leaves, tea dregs and tea stalks from agricultural and forestry wastes as raw materials, the raw materials are first washed and soaked in hot water at 60-80°C for 8 hours, and then dried in the sun at room temperature to obtain dried tea leaves, and then anaerobic Fermentation, so that the moisture content in the dry tea leaves is 2500ppm to obtain pretreated tea charcoal;

[0068] The second step: the preparation of tea charcoal

[0069] Use the pretreated tea charcoal prepared in step 1 as raw material, and then carry out low-temperature carbonization at 180-250°C for 8 hours in a nitrogen protective gas; then transfer to a high-pressure activation reactor for high-pressure activation reaction, using water as the medium, using Supercritical reaction conditions, control the pressure in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com