Preparation methods and quality control methods of polysaccharide-iron compound and capsule preparation

A technology of polysaccharide iron and complexes, which is applied in the preparation of capsule preparations and in the field of polysaccharide iron complexes. It can solve the problems affecting the quality of polysaccharide iron complexes, the difficulty of removing heavy metal ions, and the increase in the amount of polysaccharides. It achieves good separation and purification effects and reduces Heavy metal content, effect of reducing polysaccharide dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Preparation of ferric hydroxide colloid

[0056] The preparation of ferric hydroxide colloid comprises the following steps:

[0057] (1) Take by weighing anhydrous sodium carbonate 118Kg, put in reaction tank, under stirring, be mixed with water to 25% concentration, stir until anhydrous sodium carbonate dissolves completely, obtain sodium carbonate solution;

[0058] (2) Take by weighing 190Kg of Liuheshui ferric chloride, put in reaction tank, under stirring, add water and be mixed with 30% concentration, stir until Liuheshui ferric chloride dissolves completely; Under stirring, sodium carbonate solution is passed through metering pump , into the reaction tank of the solution of ferric chloride with a flow rate of about 10-12Kg per minute until the sodium carbonate solution is completely added.

[0059] (3) Reaction: After adding the sodium carbonate solution, continue to stir for 1 hour at 25° C., and use the cloud point inspection method to detect tha...

Embodiment 2

[0061] Embodiment 2: Preparation of ferric hydroxide colloid

[0062] The preparation of ferric hydroxide colloid comprises the following steps:

[0063] (1) Take by weighing anhydrous sodium carbonate 118Kg, put in reaction tank, under stirring, be mixed with water to 25% concentration, stir until anhydrous sodium carbonate dissolves completely, obtain sodium carbonate solution;

[0064] (2) Take by weighing 190Kg of Liuheshui ferric chloride, put in reaction tank, under stirring, add water and be mixed with 30% concentration, stir until Liuheshui ferric chloride dissolves completely; Under stirring, sodium carbonate solution is passed through metering pump , into the reaction tank of the solution of ferric chloride with a flow rate of about 10-12Kg per minute until the sodium carbonate solution is completely added.

[0065] (3) Reaction: After adding the sodium carbonate solution, continue to stir at 25° C. for 0.5 hour, adopt the cloud point test method to detect, the solu...

Embodiment 3

[0067] Embodiment 3: preparation ferric hydroxide colloid

[0068] The preparation of ferric hydroxide colloid comprises the following steps:

[0069] (1) Take by weighing anhydrous sodium carbonate 118Kg, put in reaction tank, under stirring, be mixed with water to 25% concentration, stir until anhydrous sodium carbonate dissolves completely, obtain sodium carbonate solution;

[0070] (2) Take by weighing 190Kg of Liuheshui ferric chloride, put in reaction tank, under stirring, add water and be mixed with 30% concentration, stir until Liuheshui ferric chloride dissolves completely; Under stirring, sodium carbonate solution is passed through metering pump , into the reaction tank of the solution of ferric chloride with a flow rate of about 10-12Kg per minute until the sodium carbonate solution is completely added.

[0071] (3) Reaction: After adding the sodium carbonate solution, continue to stir for 2 hours at 25° C., and use the cloud point inspection method to detect that ...

PUM

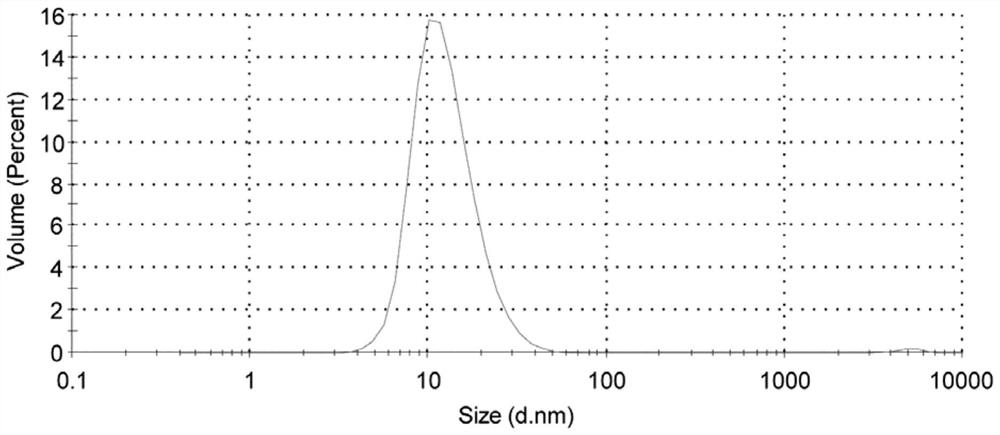

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com