Preparation method of electrospun carbon nanofiber/reduced graphene oxide/polyaniline/basic nickel carbonate composite electrode material

A carbon nanofiber and composite electrode technology, applied in graphene, carbon fiber, nanocarbon, etc., can solve the problems of unfavorable supercapacitor application, easy agglomeration, low conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

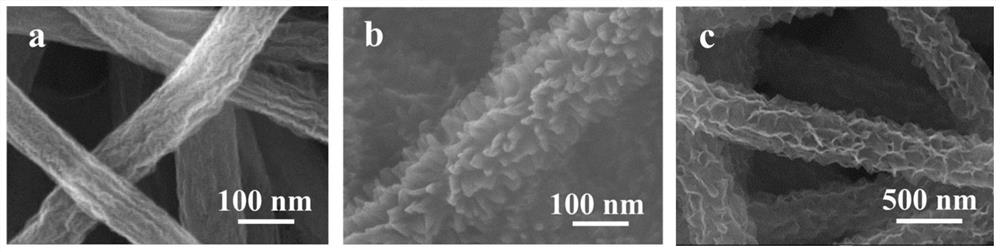

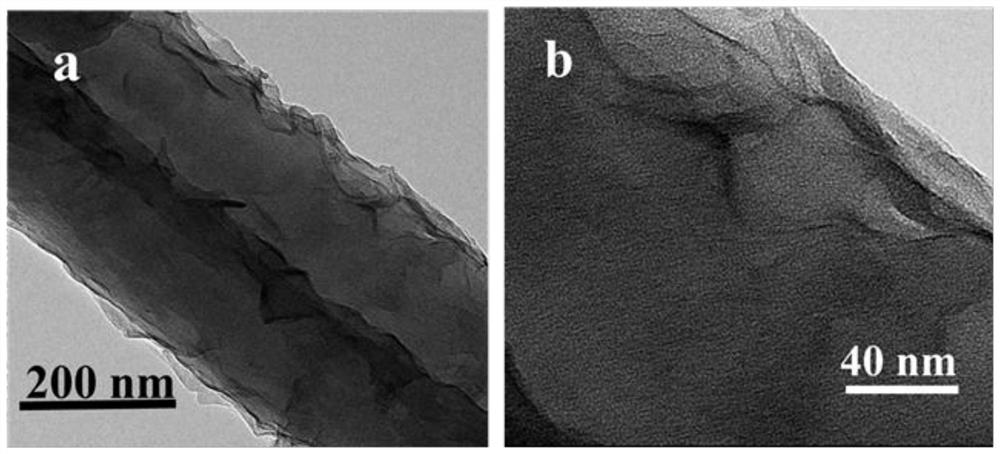

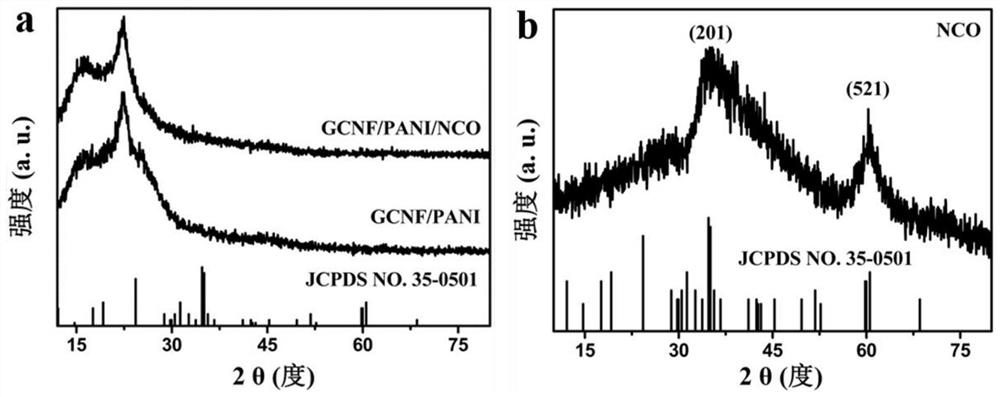

[0038] Step 1, preparation of electrospun carbon nanofiber / reduced graphene oxide (GCNF) electrode material:

[0039]First, add 1 g of polyacrylonitrile powder into 10 mL of N,N-dimethylformamide solution, heat in an oil bath at 80°C for 2 hours and stir at room temperature for 12 hours to obtain a uniform spinning solution; put the spinning solution into a syringe, Electrospinning was carried out at a voltage of 15kV, the distance between the spinning needle and the receiver was 20cm, and the injection speed was 2mL / h, and the electrospun film was collected; Pre-oxidize in the furnace, the heating time is 200min, the heating temperature is 250°C, and the holding time is 60min. The pre-oxidized film is soaked in 1mg / mL graphene oxide solution for two days, and the film is taken out and rinsed with ethanol for 3 -5 times, and dried in an oven at 50°C to obtain an electrospun film coated with a graphene oxide sheet; carbonize the film in a tube furnace under a nitrogen atmospher...

Embodiment 2

[0053] Step 1. Preparation of electrospun carbon nanofiber / reduced graphene oxide electrode material:

[0054] First, add 1 g of polyacrylonitrile powder into 10 mL of N,N-dimethylformamide solution, heat in an oil bath at 80°C for 2 hours and stir at room temperature for 14 hours to obtain a uniform spinning solution; put the spinning solution into a syringe , at a voltage of 18kV, the distance between the spinning needle and the receiver is 18cm, and the injection speed is 2.5mL / h, electrospinning is carried out, and the electrospun film is collected; the obtained electrospun film is placed in an air atmosphere at Carry out pre-oxidation in a tube furnace, the heating time is 200min, the heating temperature is 250°C, and the holding time is 60min. The pre-oxidized film is soaked in 1mg / mL graphene oxide solution for three days, and the film is taken out with ethanol Rinse 3-5 times, and dry in an oven at 50°C to obtain an electrospun membrane coated with graphene oxide sheet...

Embodiment 3

[0060] Step 1. Preparation of electrospun carbon nanofiber / reduced graphene oxide electrode material:

[0061] First, add 1 g of polyacrylonitrile powder into 10 mL of N,N-dimethylformamide solution, heat in an oil bath at 80°C for 2 hours and stir at room temperature for 10 hours to obtain a uniform spinning solution; the clear and transparent spinning solution Put it into the syringe, carry out electrospinning at a voltage of 13kV, the distance between the spinning needle and the receiver is 15cm, and the injection speed is 1.8mL / h, and collect the electrospun film; Pre-oxidize in a tube furnace under an air atmosphere, the heating time is 200min, the heating temperature is 250°C, and the holding time is 60min. The pre-oxidized film is soaked in 1 mg / mL graphene oxide solution for 2.5 days, and the The membrane was taken out and rinsed with ethanol for 3-5 times, and dried in an oven at 50°C to obtain an electrospun membrane coated with graphene oxide sheets; the membrane wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com