Epoxy adhesive with low resin precipitation and preparation method thereof

A technology of epoxy adhesives and resins, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems that affect the overall viscosity or mechanical properties of adhesives, increase production and use costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

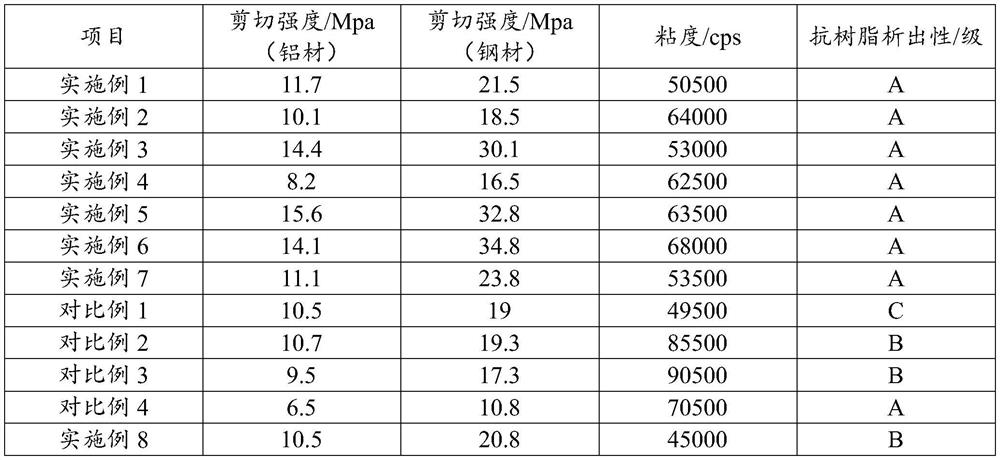

Examples

Embodiment 1

[0031] The embodiment of the epoxy adhesive with low resin precipitation of the present invention includes the following components by mass content: 45% of epoxy resin, 10% of toughening agent, 20% of inorganic filler, 1% of functional auxiliary agent, 5% of curing agent %, active diluent 10%, thixotropic agent 2%, and porous material 7%. The epoxy resin is bisphenol A epoxy resin NPEL-128; the toughening agent is styrene-butadiene rubber core-shell toughening particles MX-125; the curing agent includes 1% organic urea UR500 and 4% Dicyandiamide / organic urea DICY; the reactive diluent is 1,4-butanediol diglycidyl ether; the thixotropic agent is fumed silica; the inorganic filler is micron calcium carbonate; the function The performance aid is epoxy modified silane coupling agent KH560; the porous material is porous calcium carbonate; the specific surface area of the porous calcium carbonate is 220m 2 / g, the average particle size is 10μm; the oil absorption value is 90% of ...

Embodiment 2

[0034]The embodiment of the epoxy adhesive with low resin precipitation of the present invention includes the following components by mass content: 50% of epoxy resin, 12% of toughening agent, 14% of inorganic filler, 1% of functional auxiliary agent, 6% of curing agent %, active diluent 10%, thixotropic agent 3% and porous material 4%. The epoxy resin is bisphenol F type epoxy resin 170; the toughening agent is polybutadiene rubber core-shell toughening particles MX-153; the curing agent is modified imidazole PN23; the reactive diluent for C 12 ~C 14 Alkyl glycidyl ether; the thixotropic agent is organic bentonite; the inorganic filler is micron aluminum hydroxide; the functional additive is phosphoric acid ester; the porous material is porous aluminum hydroxide; The specific surface area of porous aluminum hydroxide is 160m 2 / g, the average particle size is 15μm; the oil absorption value is 88% of its own mass content.

[0035] The preparation method of the epoxy adhe...

Embodiment 3

[0037] The embodiment of the epoxy adhesive with low resin precipitation of the present invention includes the following components by mass content: 39% of epoxy resin, 5% of toughening agent, 15% of inorganic filler, 0.5% of functional auxiliary agent, 32% of curing agent %, active diluent 5%, thixotropic agent 2%, and porous material 1.5%. The epoxy resin is cycloaliphatic epoxy resin 2021P; the toughening agent is carboxyl-terminated liquid nitrile rubber CTBN; the curing agent is methyl hexahydrophthalic anhydride; the reactive diluent is trimethylolpropane Triglycidyl ether; the thixotropic agent is organic bentonite; the inorganic filler is micron-sized silica; the functional additive is aminosiloxane coupling agent KH550; the porous material is porous di Silicon oxide; the specific surface area of the porous calcium carbonate is 220m 2 / g, the average particle size is 10μm; the oil absorption value is 90% of its own mass content.

[0038] The preparation method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com