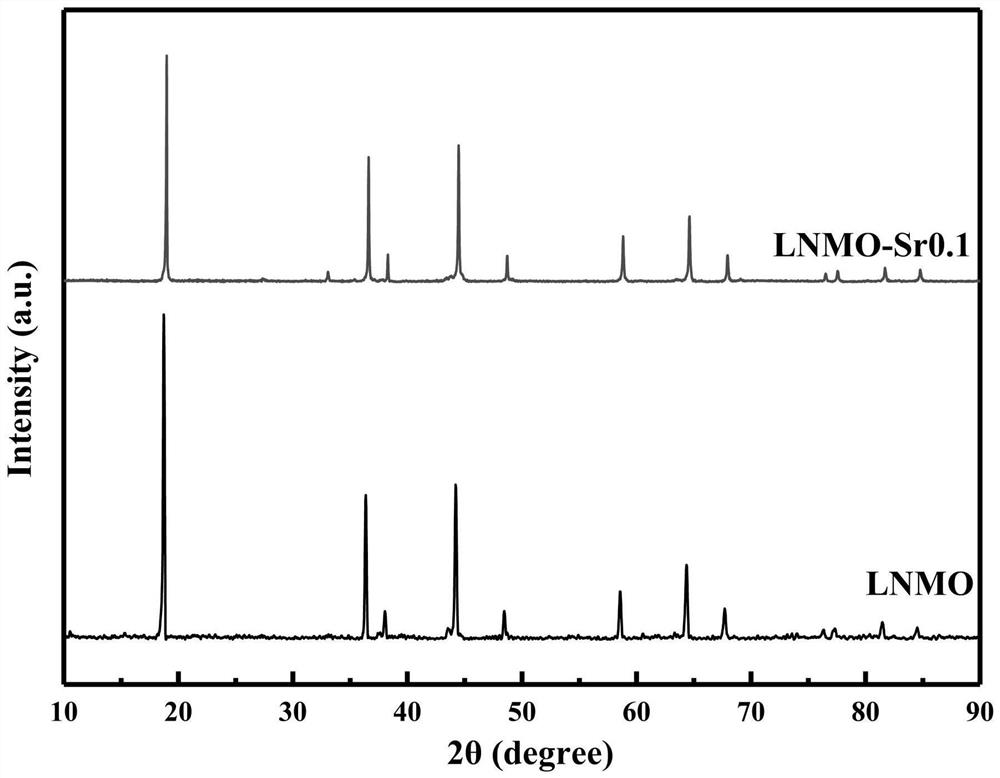

Modification method for doping and synthesizing binary lithium nickel manganese oxide positive electrode material

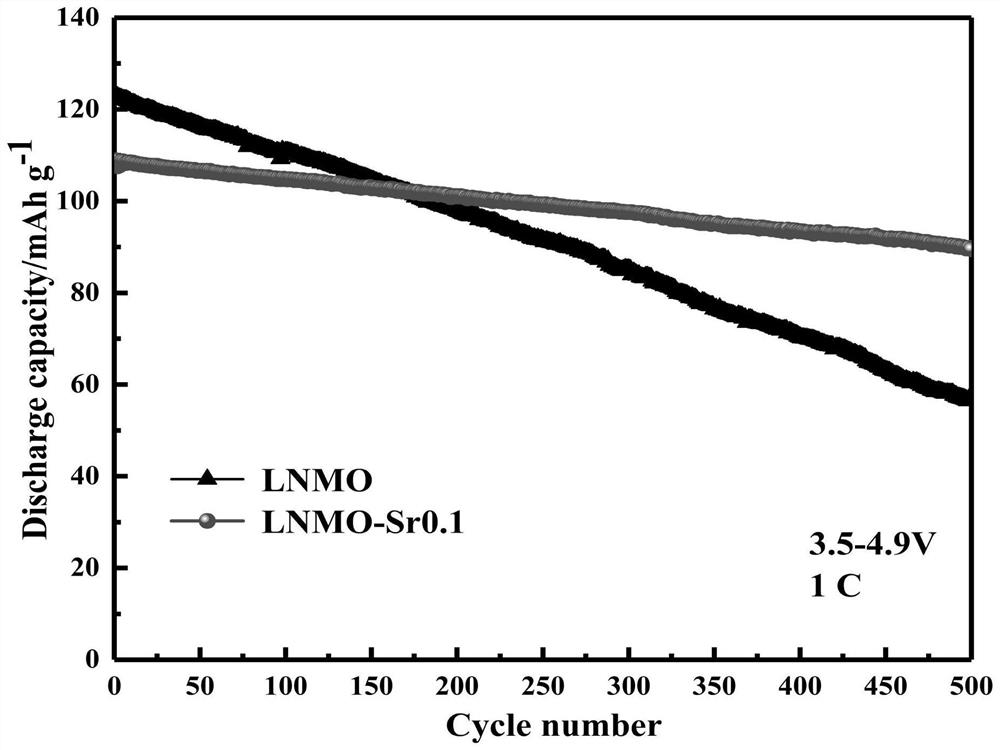

A technology of binary lithium nickel manganese oxide and positive electrode materials, which is applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problems that cannot fundamentally improve the stability of material structures, achieve the suppression of side reactions on the surface of materials, and save time , The effect of improving the capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

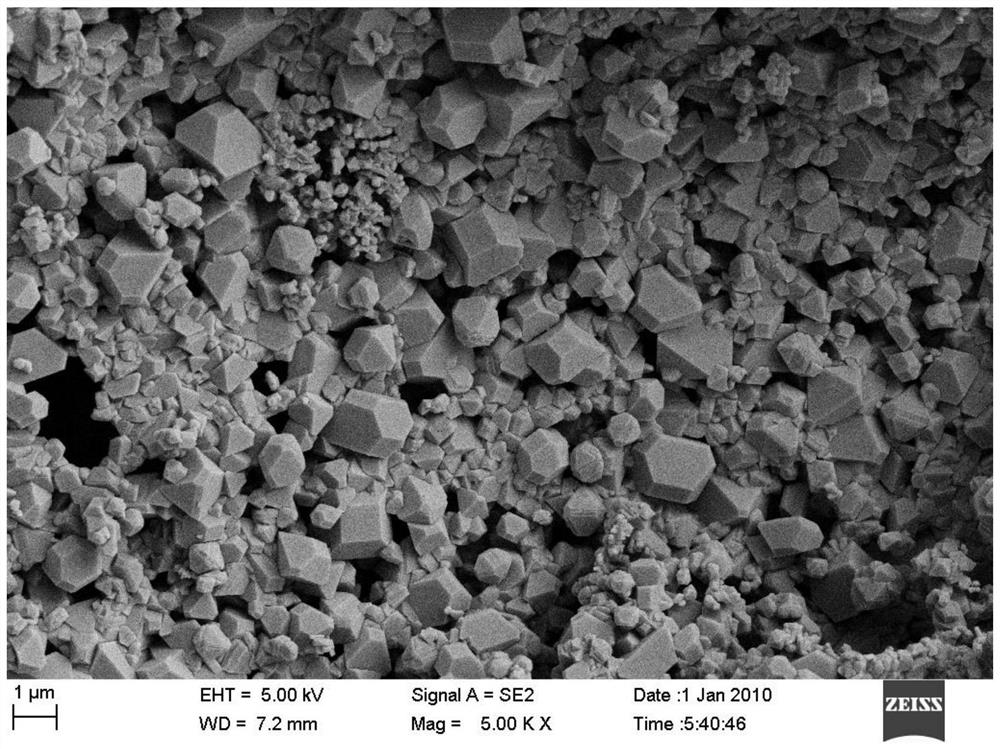

Image

Examples

Embodiment 1

[0029] Example 1. A modification method for doping and synthesizing binary lithium nickel manganese oxide cathode material, the preparation steps are as follows:

[0030] (1) Weigh 0.05mol of strontium acetate and dissolve in 200mL of deionized water with a molar ratio of 1.05:0.5:1.45 lithium acetate, nickel acetate and manganese acetate to obtain acetate solution;

[0031] (2) citric acid is dissolved in ethylene glycol at a molar ratio of 1:4, and the dissolution temperature is 80° C. to obtain a citric acid ethylene glycol solution;

[0032] (3) Add acetate solution to the citric acid ethylene glycol solution, heat and stir for about 3 hours until the solution becomes a green gel; wherein, the heating temperature is 130°C, and the stirring speed is 300r / min; an oil bath is used for heating and stirring conduct;

[0033] (4) Grind the green gel after drying at 170°C, heat it to 500°C with a heating rate of 3°C / min in a tube furnace in an air atmosphere, keep it warm for 5...

Embodiment 2

[0034] Example 2. A modification method for doping and synthesizing binary lithium nickel manganese oxide cathode material, the preparation steps are as follows:

[0035] (1) Weigh 0.10 mol of strontium acetate and dissolve in 200 mL of deionized water with a molar ratio of 1.05:0.5:1.40 lithium acetate, nickel acetate, and manganese acetate to obtain an acetate solution;

[0036] (2) citric acid is dissolved in ethylene glycol at a molar ratio of 1:4, and the dissolution temperature is 80° C. to obtain a citric acid ethylene glycol solution;

[0037] (3) Add acetate solution to the citric acid ethylene glycol solution, heat and stir for about 3 hours, until the solution becomes a green gel; wherein, the heating temperature is 130° C., and the stirring speed is 300 r / min.

[0038] (4) Grind the green gel after drying at 170°C, heat it to 500°C at a heating rate of 3°C / min in an air atmosphere, keep it for 5 hours, then raise it to 850°C at the same heating rate, and keep it f...

Embodiment 3

[0039] Example 3. A modification method for doping and synthesizing binary lithium nickel manganese oxide cathode material, the preparation steps are as follows:

[0040] (1) Weigh 0.15 mol of strontium acetate and dissolve in 200 mL of deionized water with a molar ratio of 1.05:0.5:1.35 lithium acetate, nickel acetate and manganese acetate to obtain an acetate solution;

[0041] (2) citric acid is dissolved in ethylene glycol at a molar ratio of 1:4, and the dissolution temperature is 80° C. to obtain a citric acid ethylene glycol solution;

[0042] (3) Add acetate solution to the citric acid ethylene glycol solution, heat and stir for about 3 hours, until the solution becomes a green gel; wherein, the heating temperature is 130° C., and the stirring speed is 300 r / min.

[0043] (4) Grind the green gel after drying at 170°C, heat it to 500°C at a heating rate of 3°C / min in an air atmosphere, keep it for 5 hours, then raise it to 850°C at the same heating rate, and keep it fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com