Polyurethane-based hydrogen absorption material and preparation method thereof

A technology of hydrogen-absorbing materials and polyurethane, which is applied in the field of polyurethane-based hydrogen-absorbing materials and its preparation, can solve the problems of small hydrogen-absorbing capacity, slow hydrogen-absorbing rate, and short-circuit of components, and achieve fast hydrogen-absorbing rate, improved plasticity, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of polyurethane-based hydrogen absorbing material, comprising the following steps:

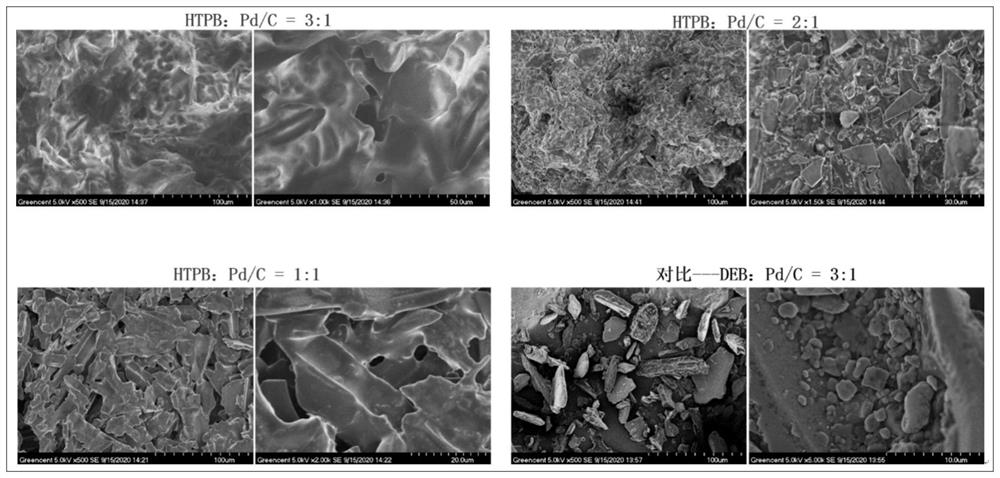

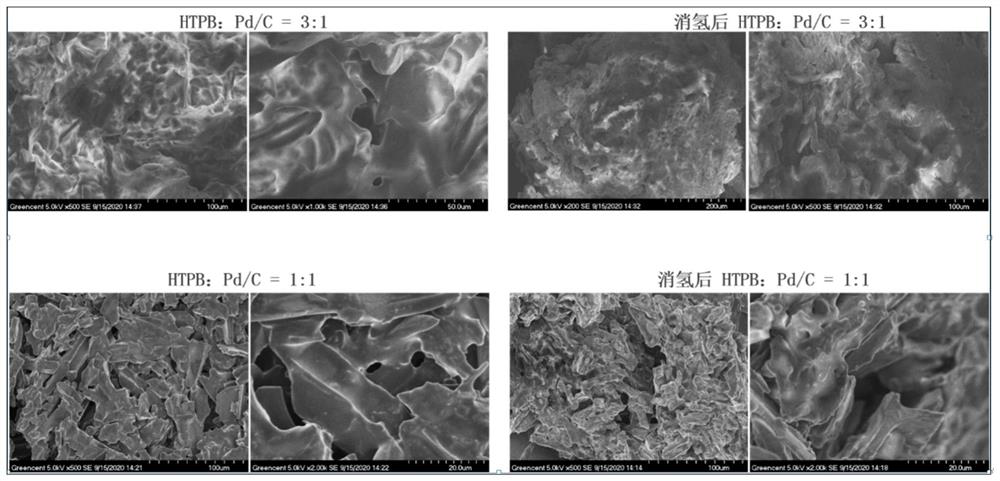

[0037] (1) Evenly mix and react hydroxyl-terminated polybutadiene and diisocyanate in proportion to obtain a polyurethane prepolymer; the ratio of hydroxyl-terminated polybutadiene to diisocyanate is 50:1-1:50.

[0038] (2) The polyurethane prepolymer prepared in step 1) is fully mixed with the noble metal catalyst loaded on the carbon material and an appropriate amount of glycol in proportion, and further reaction occurs; the polyurethane prepolymer, the noble metal loaded on the carbon material The mass ratio of the catalyst to the glycol is 1-50:1-50:1-50.

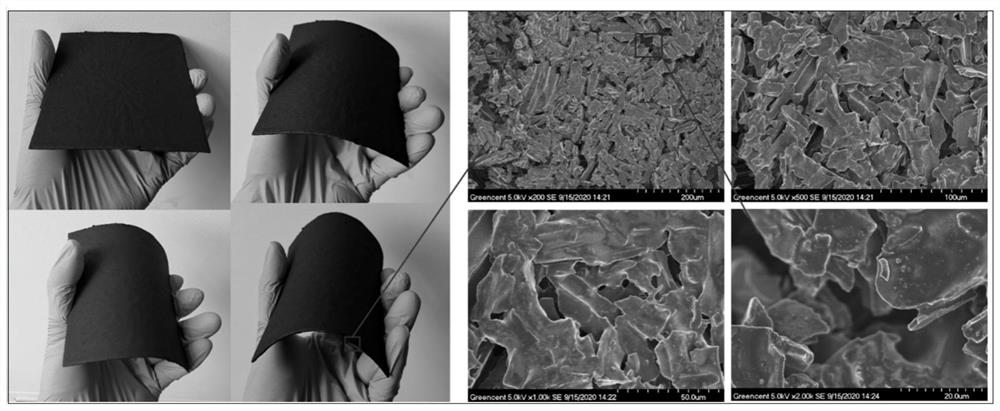

[0039] (3) Polyurethane-based hydrogen-absorbing materials in different forms can be obtained by casting, pressing or spin-coating the materials prepared in step 2).

[0040] The specific process mainly includes the modification of polyurethane with hydroxyl-terminated polybutadiene, and fully mixing with th...

Embodiment 1

[0055] Get 1% hydroxyl-terminated polybutadiene (HTPB) (5 parts,) and join in the homogenizer sample tank, then add cyclohexane dimethylene diisocyanate (0.5 part), after that the sample The tank is loaded into a homogenizer, and the homogenate is carried out for 10 minutes under the condition of 2000 rpm, so that it is fully reacted to obtain a polyurethane prepolymer. After that, 1% platinum carbon (1.25 parts) and an appropriate amount of ethylene glycol were added to the sample tank, and the homogenization was continued for 10 minutes under the condition of 2000 rpm, so as to obtain the black elastomeric polyurethane-based hydrogen absorbing material 1, After testing, its hydrogen absorption capacity at 298K, 1bar is 29.0ml / g.

Embodiment 2

[0057] Get hydroxyl-terminated polybutadiene (HTPB) (5.0 parts) with a hydroxyl value of 1% and add it to the sample tank of the homogenizer, then add isophorone diisocyanate (0.5 part), and then put the sample tank into the homogeneous pulper, under the condition of 2000 rev / min, homogenate for 10 minutes, make it fully react to obtain polyurethane prepolymer. After that, 1% palladium carbon (1.67 parts) and an appropriate amount of ethylene glycol were added to the sample tank, and under the condition of 2000 rpm, the homogenization was continued for 10 minutes, thereby obtaining a black elastomeric polyurethane-based hydrogen absorbing material 2, After testing, its hydrogen absorption capacity at 298K, 1bar is 62.0ml / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com