Steel bar anti-corrosion paint for autoclaved aerated concrete slab and preparation method of steel bar anti-corrosion paint

A concrete slab, autoclaved aeration technology, applied in anti-corrosion coatings, coatings, carboxyl rubber coatings, etc., can solve the problems of low adhesion between paint and steel bars, affecting the durability of concrete structures, and easy corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

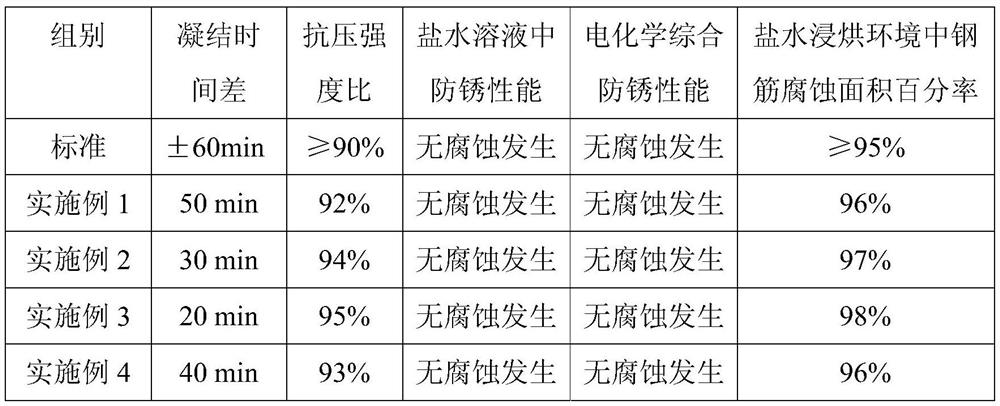

Examples

Embodiment 1

[0027] A preparation method for steel bar anticorrosion paint for autoclaved aerated concrete slabs, comprising the following steps:

[0028] S1: Weigh 350kg of epoxy resin, 50kg of carboxylated styrene-butadiene latex, 18kg of aniline, 20kg of β-naphthalenesulfonic acid, 20kg of ammonium persulfate, 1kg of strontium molybdate, 8kg of aluminum tripolyphosphate, 1kg of zinc calcium phosphomolybdate, and silicon carbide 1kg, sodium dodecylbenzenesulfonate 0.2kg, calcium hydroxide 4kg, ammonium polycarboxylate 0.1kg, N-methylpyrrolidone 0.1kg, emulsified silicone oil 0.05kg, polyether siloxane copolymer 0.1kg, ammonia water 0.05 kg, N,N-dimethylethanolamine 0.05kg, ethylene glycol monobutyl ether 0.5kg, polyamide 20kg; disperse strontium molybdate in water to obtain dispersion A, aniline, β-naphthalenesulfonate at 1°C Dissolve the acid in the dispersion liquid A, ultrasonically disperse for 5 minutes under the ultrasonic intensity of 200W to obtain a mixed liquid, add ammonium pe...

Embodiment 2

[0032] A preparation method for steel bar anticorrosion paint for autoclaved aerated concrete slabs, comprising the following steps: S1: weighing 200kg of epoxy resin, 80kg of carboxylated styrene-butadiene latex, 15kg of aniline, 30kg of β-naphthalenesulfonic acid, 15kg of ammonium persulfate, Strontium molybdate 2kg, aluminum tripolyphosphate 5kg, zinc calcium phosphomolybdate 2kg, silicon carbide 3kg, sodium dodecylbenzenesulfonate 0.5kg, calcium hydroxide 8kg, ammonium polycarboxylate 0.1kg, N-methylpyrrolidone 3kg, emulsified silicone oil 1kg, octanol 1kg, polyether siloxane copolymer 2kg, 2-amino-2-methyl-1-propanol 2kg, propylene glycol methyl ether 0.8kg, polyamide 12kg; disperse strontium molybdate in Dispersion A was obtained in water, and aniline and β-naphthalenesulfonic acid were dissolved in dispersion A at 2°C, and ultrasonically dispersed at 300W ultrasonic intensity for 20 minutes to obtain a mixed solution, and ammonium persulfate was added dropwise to the mix...

Embodiment 3

[0036]A preparation method for steel bar anticorrosion paint for autoclaved aerated concrete slabs, comprising the following steps: S1: weighing 500kg of epoxy resin, 85kg of carboxylated styrene-butadiene latex, 10kg of aniline, 31kg of β-naphthalenesulfonic acid, 17kg of ammonium persulfate, Strontium molybdate 2kg, aluminum tripolyphosphate 7kg, zinc calcium phosphomolybdate 3kg, silicon carbide 4kg, sodium dodecylbenzenesulfonate 0.6kg, calcium hydroxide 2kg, ammonium polycarboxylate 0.2kg, N-methylpyrrolidone 1.3kg, emulsified silicone oil 1.1kg, polyether siloxane copolymer 2kg, ammonia water 1.3kg, triethanolamine 0.2kg, propylene glycol methyl ether 0.8kg, polyamide 15kg; disperse strontium molybdate in water to obtain dispersion A, in Dissolve aniline and β-naphthalenesulfonic acid in dispersion liquid A at 2°C, and disperse ultrasonically at 300W for 20 minutes to obtain a mixed liquid. Add ammonium persulfate dropwise to the mixed liquid, and then magnetically stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com