Bifunctional oxygen electrocatalyst taking hollow carbon nanotube as carrier, preparation and application

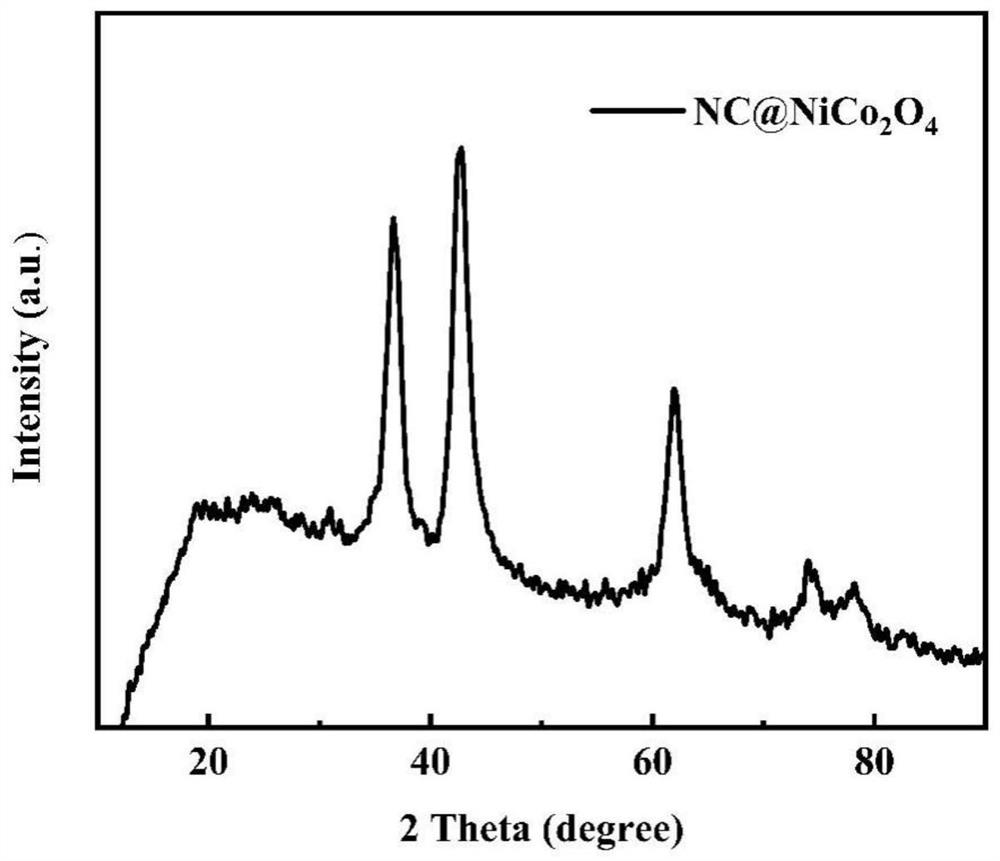

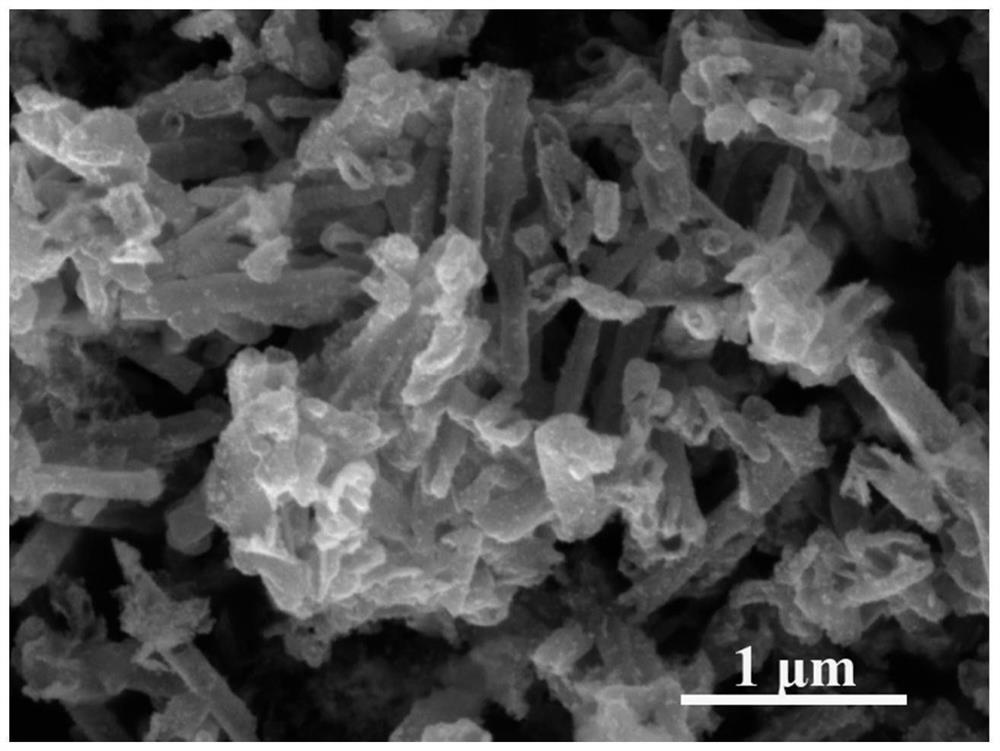

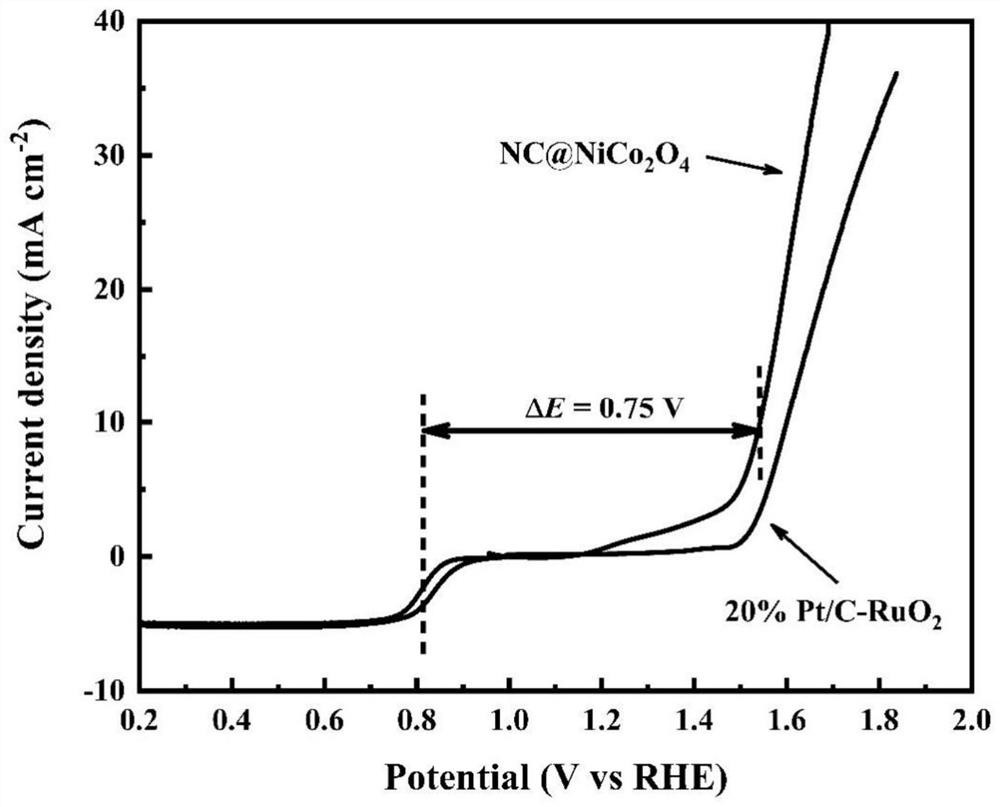

A carbon nanotube, dual-function technology, applied in the field of new energy materials, can solve the problems of poor scarcity and stability, high cost, hindering zinc air, etc., and achieve the effects of good crystallinity, lower production cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this example, the preparation of a bifunctional oxygen electrocatalyst with hollow carbon nanotubes as a carrier includes the following specific steps:

[0048] S1 Disperse 10g of HNTs in Tris-HCl (trishydroxymethylaminomethane) buffer solution with a pH value of 8.5, add 10g of dopamine hydrochloride after ultrasonication for 0.5h, stir magnetically at room temperature for 5h, centrifuge and wash and collect the precipitate, at 60°C Dry under vacuum for 12h to obtain HNTs@PDA nanomaterials.

[0049] S2 Put the HNTs@PDA nanomaterials prepared in step S1 in a tube furnace, heat up to 800°C at a rate of 5°C / min, and calcine them, and keep them warm for 3 hours under this condition. The whole reaction system is under a nitrogen atmosphere, and then Cool to room temperature to obtain HNTs@NC nanomaterials, then disperse HNTs@NC nanomaterials in HF, stir magnetically at room temperature for 4 h, centrifuge and wash and collect precipitates, and vacuum dry at 60 °C for 12 ...

Embodiment 2

[0060] In this example, the preparation of a bifunctional oxygen electrocatalyst with hollow carbon nanotubes as a carrier includes the following specific steps:

[0061] S1 Disperse 10g of halloysite nanotubes (HNTs) in an ammonia solution with a pH value of 8, add 12g of dopamine hydrochloride (PDA) after ultrasonication for 1h, stir magnetically for 4h at room temperature, wash by centrifugation and collect the precipitate, vacuum at 60°C After drying for 12 hours, HNTs@PDA nanomaterials were obtained.

[0062] S2 Place the HNTs@PDA nanomaterial prepared in step S1 in a tube furnace, heat up to 700°C at a rate of 5°C / min for calcination, and keep it warm for 3 hours under this condition. The entire reaction system is under a nitrogen atmosphere, and then cooled to At room temperature, HNTs@NC nanomaterials were obtained, and then the HNTs@NC nanomaterials were dispersed in hydrofluoric acid, magnetically stirred at room temperature for 5 hours, centrifuged and washed to col...

Embodiment 3

[0066] In this example, the preparation of a bifunctional oxygen electrocatalyst with hollow carbon nanotubes as a carrier includes the following specific steps:

[0067] S1 Disperse 10g of halloysite nanotubes (HNTs) in an ammonia solution with a pH value of 10, add 8g of dopamine hydrochloride (PDA) after ultrasonication for 1h, stir magnetically for 4h at room temperature, wash by centrifugation and collect the precipitate, vacuum at 70°C After drying for 10 h, HNTs@PDA nanomaterials were obtained.

[0068] S2 Put the HNTs@PDA nanomaterial prepared in step S1 in a tube furnace, raise the temperature to 900°C at a rate of 5°C / min, keep it warm for 2h under this condition, and then calcine it. The whole reaction system is cooled to room temperature under a nitrogen atmosphere , to obtain HNTs@NC nanomaterials, and then disperse HNTs@NC nanomaterials in hydrofluoric acid, magnetically stir at room temperature for 3 hours, centrifuge and wash and collect precipitates, and vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com