Preparation method of vanadium carbide nanosheet

A vanadium carbide nano, self-propagating technology, applied in chemical instruments and methods, carbon compounds, nanotechnology, etc., can solve the problems of high energy consumption, large heating and cooling temperature gradients, dense structure, etc. Good capacitance performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

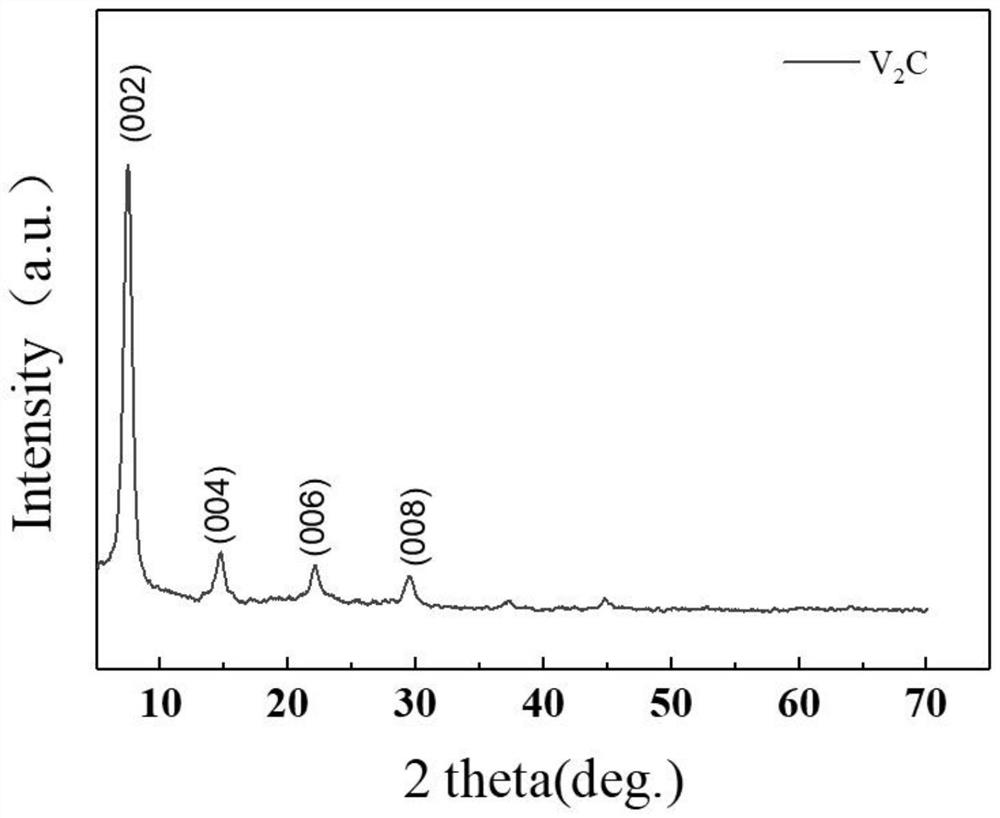

[0027] A method for preparing vanadium carbide nanosheets, comprising the steps of:

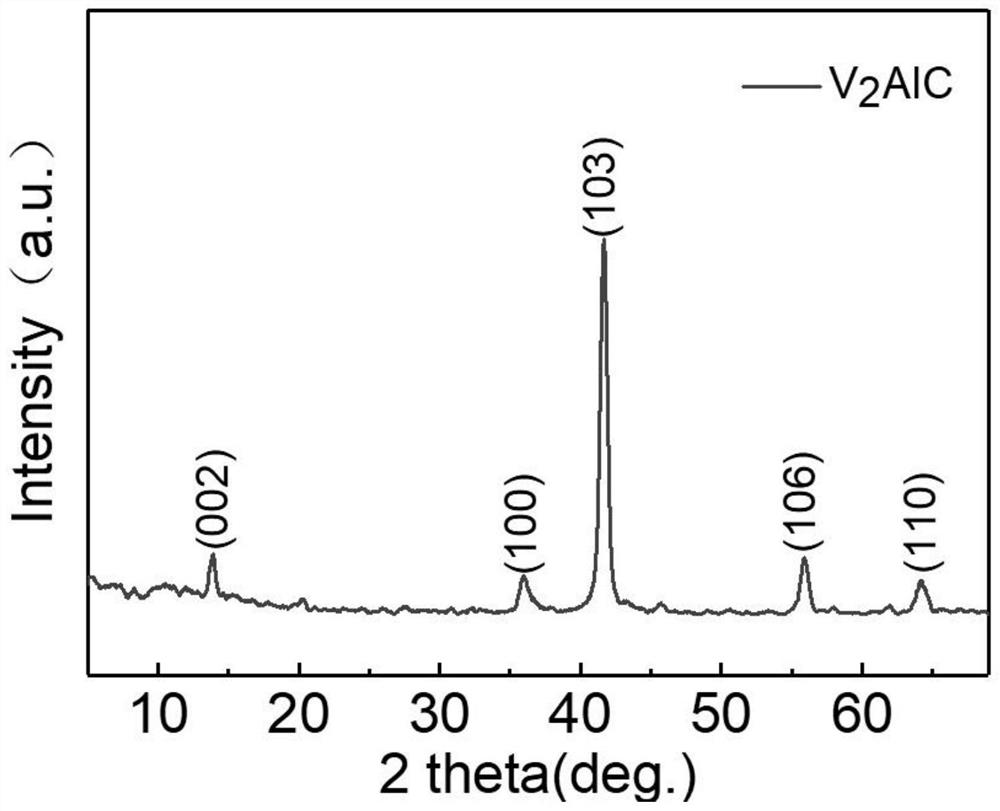

[0028] (1) According to the molar ratio of V powder: Al powder: C powder = 2:1.2:1, take 100 grams of raw material powders, mix them and place them in argon atmosphere for ball milling (the ball-to-material ratio is 6:1, and the ball milling rate is 300r / min, ball milling time is 4h), obtains solid phase powder;

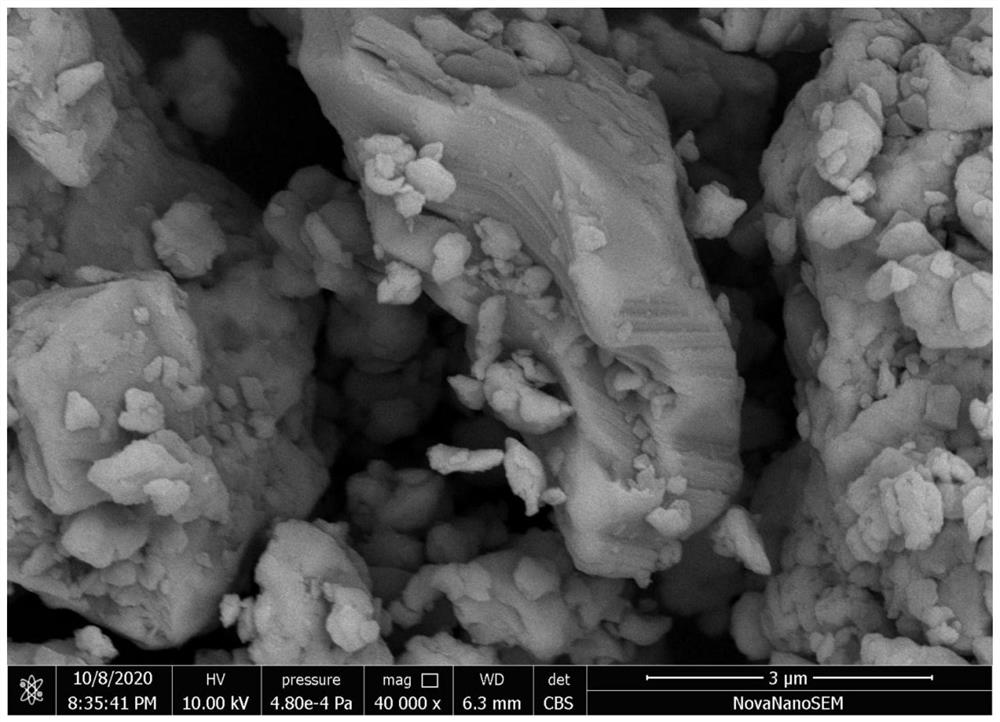

[0029] (2) Put the solid phase powder into a graphite box with carbon cloth on the inner layer and coated with boron nitride on the surface, roll the tungsten wire into a filament shape and put it in the middle of the powder, and put the graphite box into the self-propagating reaction kettle , carry out self-propagating reaction under argon atmosphere, control the argon pressure at 0.3MPa, ignite at high temperature, the ignition time is 2-6s, take it out after the reaction kettle is cooled to room temperature, pulverize the reaction product, and ball mill it under argon atmosphere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com