Lithium and sodium ion battery negative electrode material nickel pyrovanadate and sol-gel combined annealing preparation method and application thereof

A sodium ion battery, nickel pyrovanadate technology, applied to battery electrodes, negative electrodes, nickel compounds, etc., can solve the problems of increasing the difficulty of sodium ion de-intercalation, unfavorable large-scale production, unfavorable large-scale production, and the like. The reaction process is easy to control, the production cost is reduced, and the reaction time is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

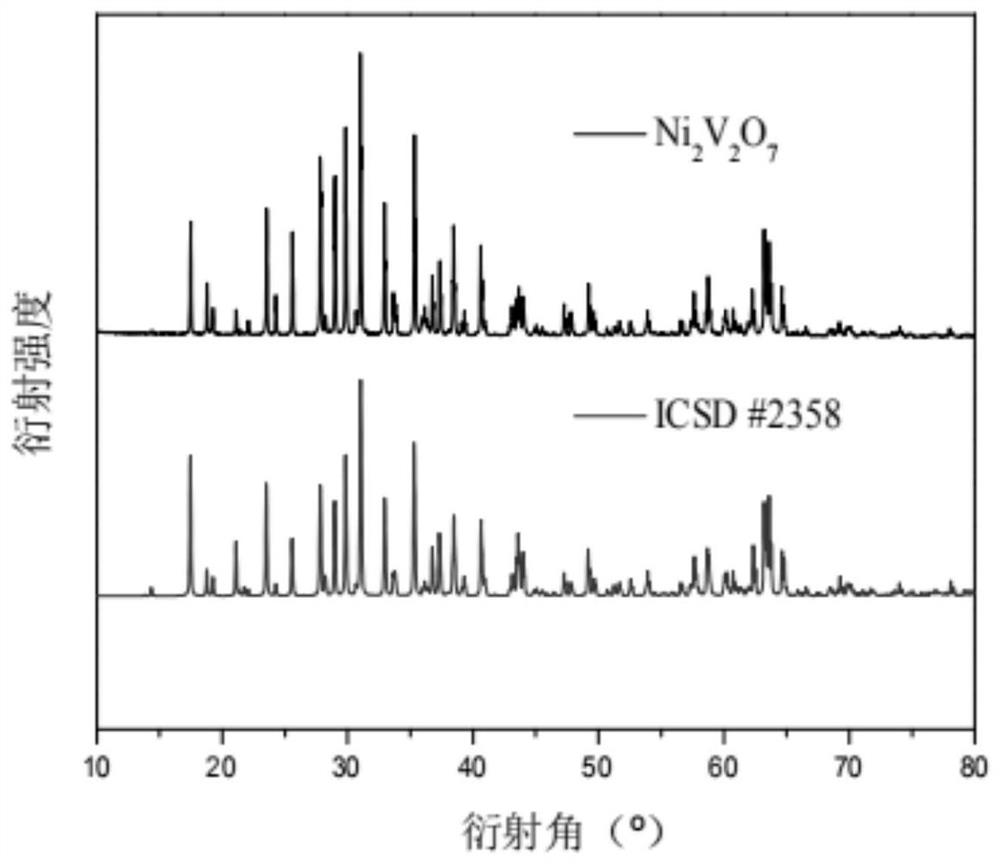

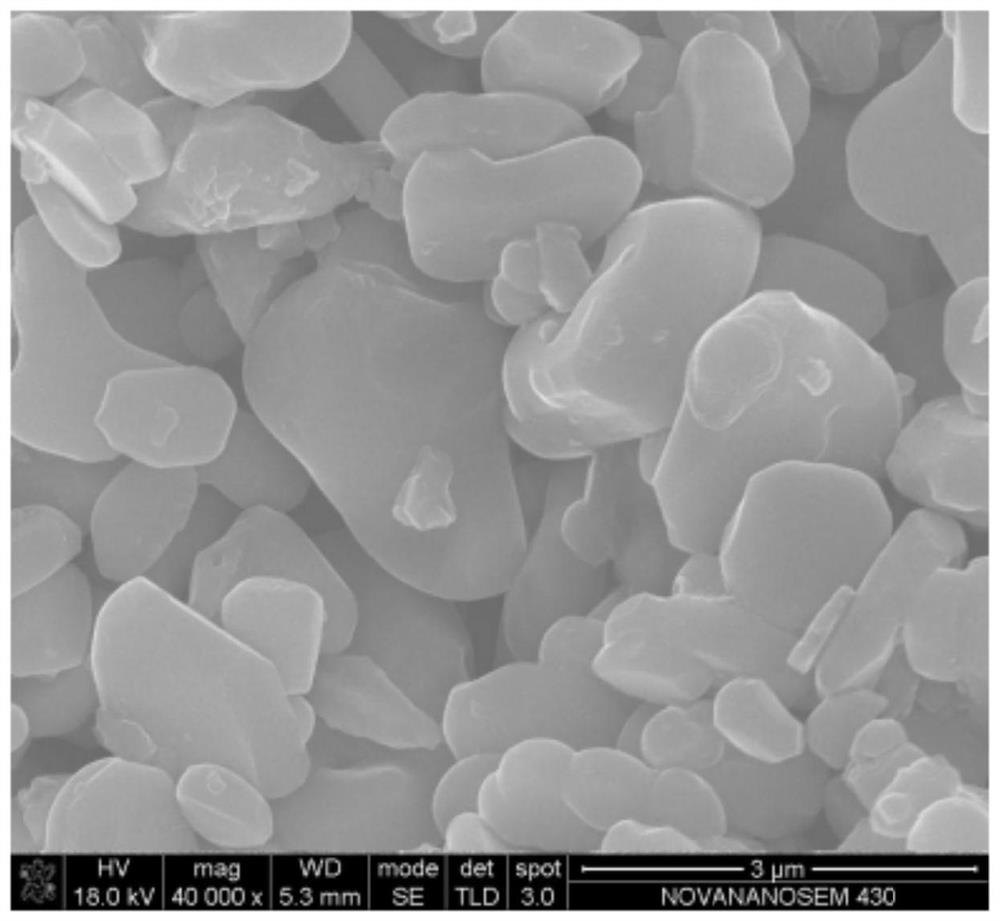

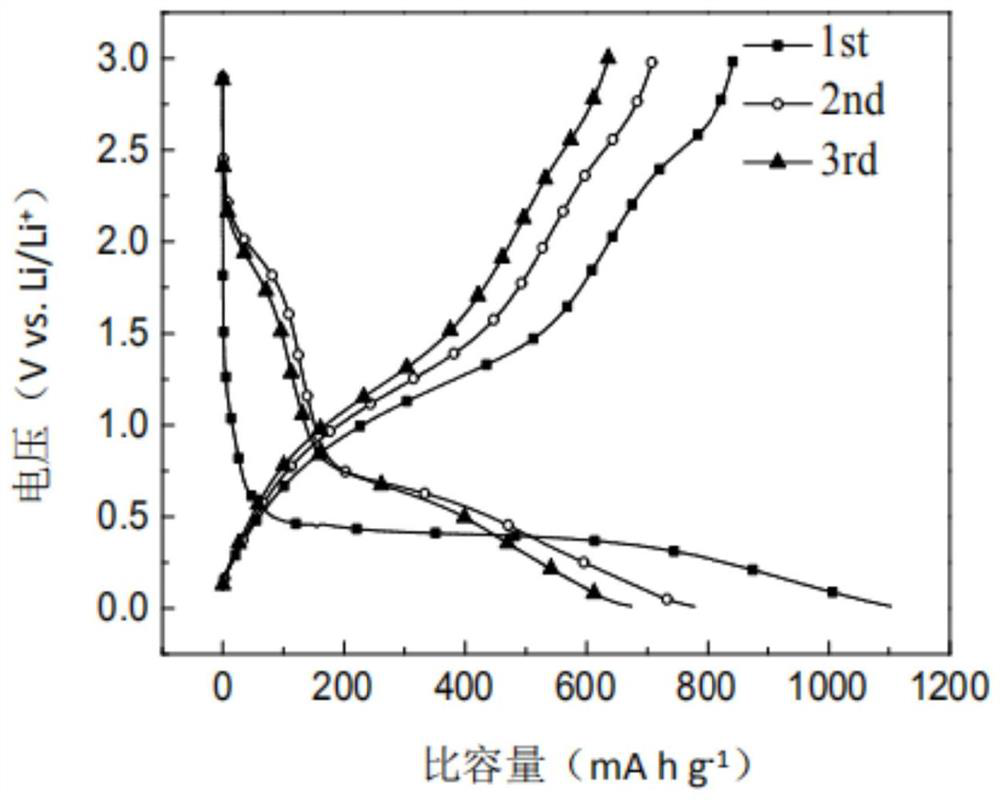

[0044] After weighing ammonium metavanadate, citric acid and nickel nitrate hexahydrate according to the stoichiometric ratio of V:C:Ni=1:1:1, first add ammonium metavanadate to 50°C distilled water, then add citric acid to set Stir on a magnetic stirrer for half an hour, then add nickel nitrate hexahydrate and continue stirring at 60°C for 3 hours to obtain a colloid; put the obtained colloid in an air drying oven at 110°C to dry and air-dry, after 12 hours Get precursors. Grind the precursor and press it into a dense thin disc with a thickness of 0.5mm, then pretreat it at 300°C for 6h under an inert gas atmosphere, and after natural cooling, grind to obtain a powder product; grind the powder product again Afterwards, it is pressed again to be a dense thin disc with a thickness of 0.5 mm, put into a tube furnace and sinter 20 h at 650 ° C under an Ar atmosphere, and after natural cooling, a pure-phase nickel pyrovanadate negative electrode material (such as figure 1 shown)....

Embodiment 2

[0050] After weighing vanadium pentoxide, citric acid and nickel acetate according to the stoichiometric ratio of V:C:Ni=1:2:1, first add vanadium pentoxide to distilled water at 55°C, then add citric acid and place in a magnetic Stir on the stirrer for half an hour, then add nickel acetate and continue stirring at 60°C for 3 hours to obtain a colloid; put the obtained colloid in an air drying oven at 110°C to dry and air-dry, and obtain a precursor after 12 hours. Grind the precursor and press it into a dense thin disc with a thickness of 0.6mm, and then pretreat it at 400°C for 5.5h under an inert gas atmosphere, and after natural cooling, a powdery product is obtained; the powdery product is ground again Afterwards, it was pressed again into a dense thin disc with a thickness of 0.6 mm, put into a tube furnace and sintered at 900° C. for 10 h under an Ar atmosphere, and cooled naturally to obtain a nickel pyrovanadate negative electrode material.

[0051] The XRD pattern of...

Embodiment 3

[0053] After weighing vanadium pentoxide, glucose and nickel nitrate according to the stoichiometric ratio of V:C:Ni=2:1:2, first add vanadium pentoxide to distilled water at 60°C, then add glucose and place in a magnetic stirrer Stir for half an hour, then add nickel nitrate and continue stirring at 60°C for 3 hours to obtain a colloidal body; put the obtained colloidal body in an air drying oven at 110°C to dry and air-dry, and obtain a precursor after 12 hours. Grind the precursor and press it into a dense thin disc with a thickness of 0.8mm, and then pretreat it at 450°C for 5 hours under an inert gas atmosphere, and after natural cooling, a powdery product is obtained; after grinding the powdery product again Press again to form a dense thin disc with a thickness of 0.8 mm, put it into a tube furnace for sintering at 750° C. for 18 hours under an Ar atmosphere, and obtain a nickel pyrovanadate negative electrode material after natural cooling.

[0054] The XRD pattern of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com