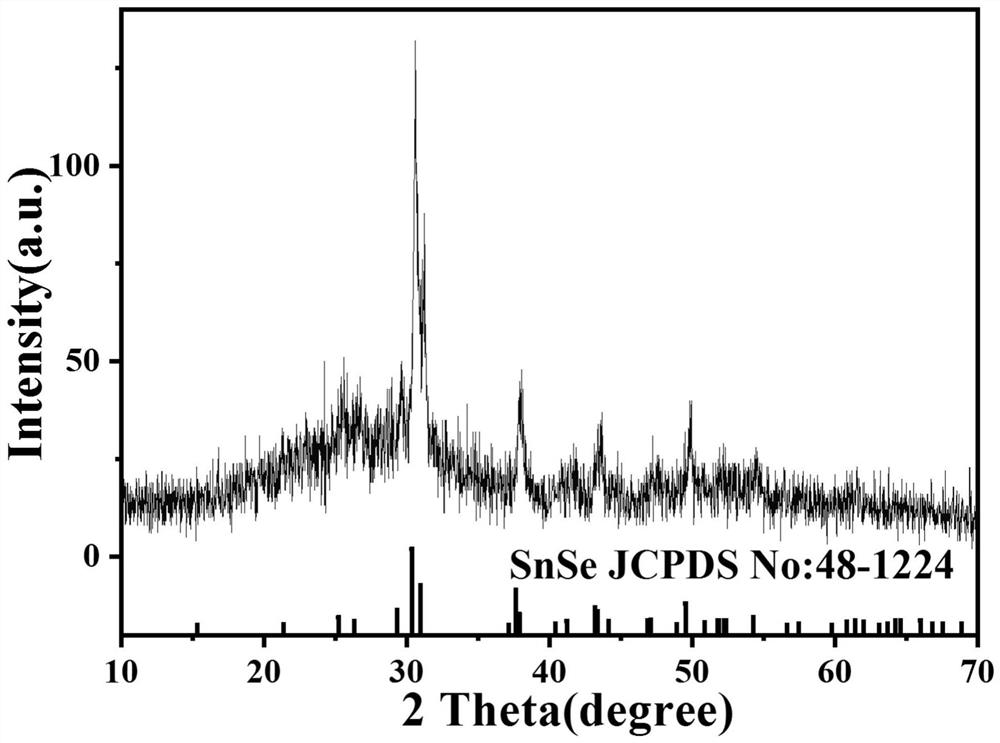

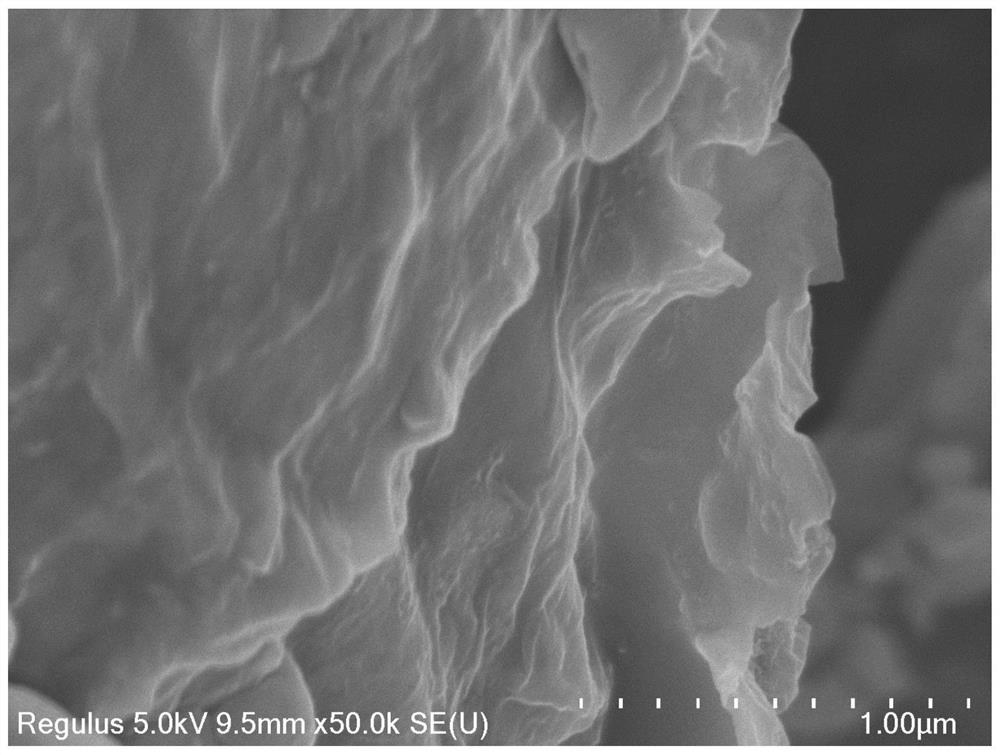

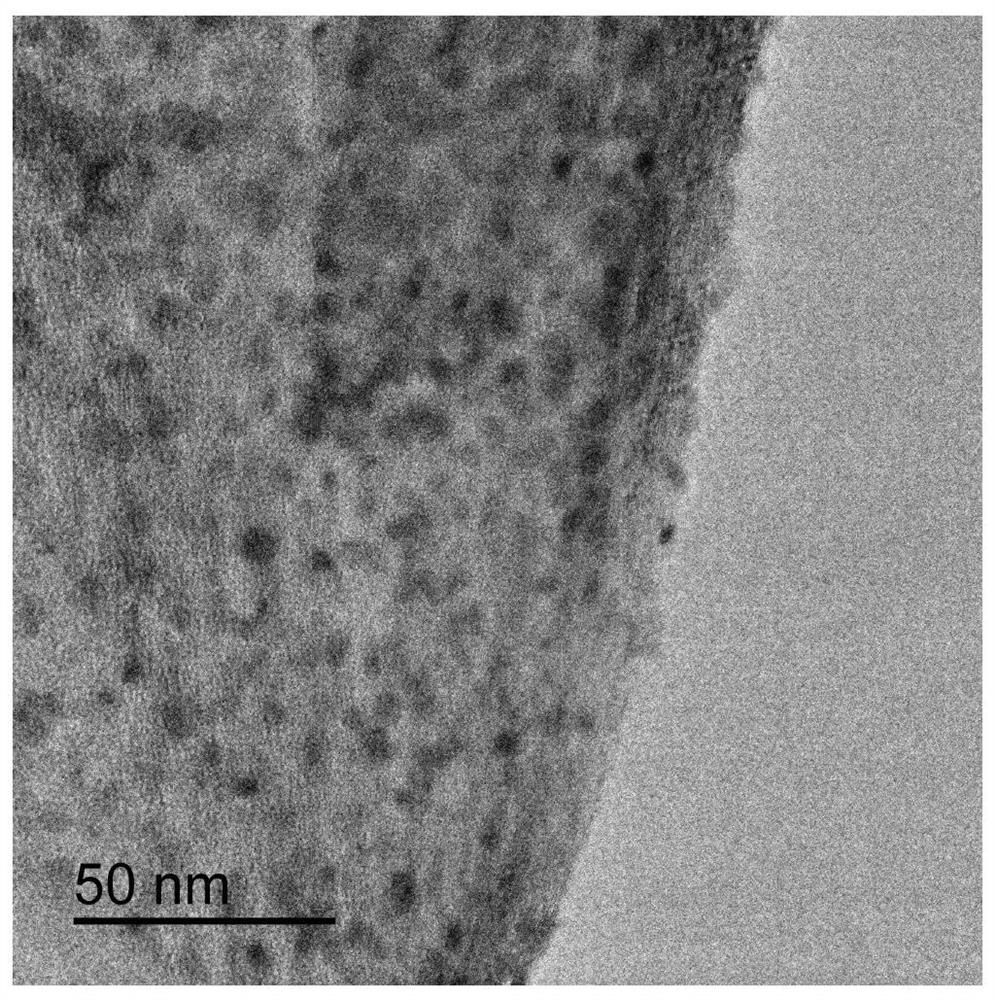

Carbon-coated SnSe/r-GO@ C compound with sandwich-like structure and preparation method and application thereof

A sandwich, carbon coating technology, applied in structural parts, active material electrodes, nanotechnology for materials and surface science, etc., to achieve the effect of improving electrochemical performance, high repeatability, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method and application of a carbon-coated sandwich structure SnSe / r-GO@C composite, comprising the following steps:

[0027] Step 1): Add 30-90 mg of graphene oxide GO into 30-70 mL of ethylene glycol or glycerin solvent, and add 0.05696 g-5.696 g of SnCl after ultrasonic dispersion 2 2H 2 O, after stirring evenly, add 0.02g~0.2g of oleic acid until completely dissolved to form solution A; add 0.01975g~1.975g of selenium powder to 3~10ml of ethylenediamine, triethanolamine, hydrazine hydrate or hydroboration In sodium aqueous solution, stir until completely dissolved to obtain solution B; then add solution B dropwise to solution A to form mixed solution C, and stir evenly; wherein, the molar ratio of tin ions to selenium ions is 1: (1~4) ; The concentration of graphene oxide in solution A is 1-2 mg·mL -1 ;

[0028] Step 2): Transfer the mixed solution C to a hydrothermal kettle, then place the hydrothermal kettle in a hydrothermal...

Embodiment 1

[0033] Preparation methods include:

[0034] 1) Add 30 mg of graphene oxide GO to 30 mL of ethylene glycol, ultrasonically disperse and add 0.07595 g of SnCl 2 2H 2 O, after stirring evenly, add 0.02g of oleic acid until completely dissolved to form solution A; add 0.0263g of selenium powder to 3ml of ethylenediamine aqueous solution, stir until completely dissolved to obtain solution B; then add solution B dropwise Add solution A to form mixed solution C, and stir evenly;

[0035] 2) Transfer the mixed solution C to a hydrothermal kettle, then place the hydrothermal kettle in a hydrothermal reactor, and fully react at 120 ° C. After the reaction is completed, cool to room temperature with the furnace to obtain a black mixed solution D; 10 g of graphite oxide Add alkene into 10ml of ethylene glycol, ultrasonically disperse evenly to obtain solution E, add solution E to solution D, and stir to obtain mixed solution F; transfer mixed solution F to a hydrothermal kettle, and th...

Embodiment 2

[0038] Preparation methods include:

[0039] 1) Add 45mg of graphene oxide GO to 50mL of glycerol, ultrasonically disperse and add 0.52785g of SnCl 2 2H 2 O, after stirring evenly, add 0.08g of oleic acid until completely dissolved to form solution A; add 0.0789g of selenium powder to 5ml of triethanolamine aqueous solution, stir until completely dissolved to obtain solution B; then add solution B dropwise to the solution A mixed solution C is formed in A and stirred evenly;

[0040] 2) Transfer the mixed solution C to a hydrothermal kettle, then place the hydrothermal kettle in a hydrothermal reactor, and fully react at 140 ° C. After the reaction is completed, cool to room temperature with the furnace to obtain a black mixed solution D; 10 g of graphite oxide Add alkene into 10ml of glycerin, ultrasonically disperse evenly to obtain solution E, add solution E to solution D, stir evenly to obtain mixed solution F, transfer mixed solution F to a hydrothermal kettle, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com