4,6-alpha-glucosyltransferase and application thereof in improving quality of steamed buns

A glucose-based and transferase technology, applied in the field of genetic engineering, can solve the problems of low molecular weight of modified dextrin, increase the shelf life of steamed bread, and high molecular weight, and achieve the effects of high raw material utilization rate, improved texture and taste, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Heterologous expression of 4,6-α-glucosyltransferase (Gtf16) derived from Lactobacillus fermentum

[0043] Using the plasmid with the full-length gtf16 gene (nucleotide sequence shown in SEQ ID NO.2) as a template, design primers, obtain the target gene 4,6-α-glucosyltransferase gene (gtf16) after PCR, and construct Recombinant plasmid pBSMuL3-gtf16. Specific steps are as follows:

[0044] PCR primers:

[0045] D-F: CCATGGGGAAACTGCTGAAAACCCTG (SEQ ID NO. 3);

[0046] D-R: TTCGAATAGTAGAAGTTATAAGCGTATTATT (SEQ ID NO. 4).

[0047]The PCR system is: 20 μM primers D-F and D-R 0.5 μL each, dNTP Mix 4 μL, 5xPS Buffer 10 μL, 2.5 U / μL PrimeStar polymerase 0.5 μL, template 0.5 μL, add double distilled water to make up 50 μL.

[0048] PCR conditions: pre-denaturation at 94°C for 4min; denaturation at 98°C for 10s, annealing at 55°C for 10s, extension at 72°C for 3.5min, 30 cycles.

[0049] The PCR product was gel-recovered, ligated with the cloning vector pMD18T ov...

Embodiment 2

[0051] Embodiment 2: Shake flask fermentation produces enzyme

[0052] The recombinant strain obtained in Example 1 was inoculated in LB medium, and after culturing at 37°C for 8 hours, it was transferred to 50mL TB fermentation medium with a 5% inoculum amount, and then expanded and cultivated at 37°C and 200rpm at a constant temperature for 1 -2h, at cell OD 600 When the growth rate reaches 0.5-1.0, isopropyl-β-D-thiogalactopyranoside (IPTG) (final concentration: 0.08mmol / L) is added, and finally placed at 25°C and 200rpm for 24h shake flask fermentation. After the fermentation is finished, the fermented liquid is crushed by high-pressure homogenization and then centrifuged, and the supernatant is the 4,6-α-glucosyltransferase enzyme liquid produced by the recombinant bacteria.

Embodiment 3

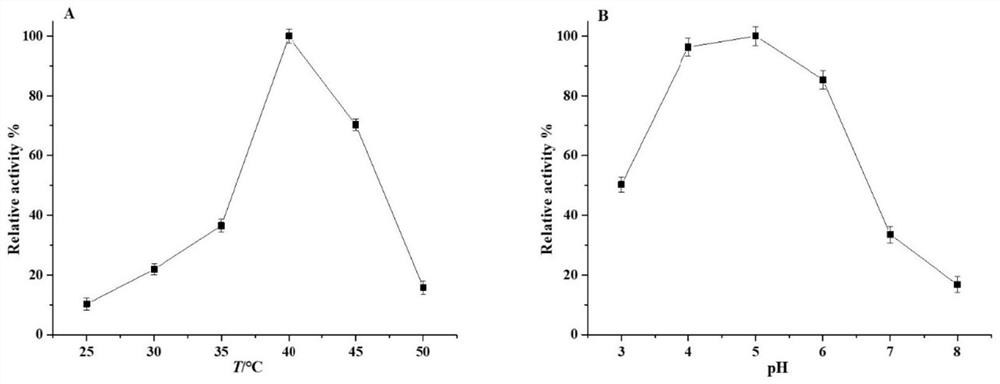

[0053] Example 3: 4,6-α-glucosyltransferase enzyme activity assay

[0054] 1. Enzyme activity assay

[0055] The total enzyme activity of Gtf16 obtained from fermentation in Example 3 was determined by the iodine method. Iodine reagent: Dissolve 2.6gI with appropriate distilled water 2 Dissolve with 26g KI, transfer it to a 100mL volumetric flask, store at 4°C, and dilute with distilled water at a ratio of 1:260 before use.

[0056] During the reaction, at 40°C, with amylose (0.125%, w / v, i.e. 1.25g / L) as the substrate, in 0.2mol / LNa 2 HPO 4 Enzyme activity was measured in -0.1mol / L citric acid buffer (pH 5.0). During the reaction, take 200 μL of the substrate in a 1.5 mL centrifuge tube and incubate at 40° C. for 10 min. Add 200 μl of Gtf16 enzyme solution and react at 40°C for 10 minutes. After the reaction, take 200 μl of the reaction solution and add it to 3800 μL of iodine chromogenic solution for 5 minutes. Measure the absorbance at 660 nm with a spectrophotometer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com