Magnesium-based metal microtubule for medical implantation and preparation method thereof

A magnesium-based metal and microtube technology, applied in the fields of cardiovascular and cerebrovascular repair and implant materials antibacterial, nerve repair implants, can solve the problems of unsatisfactory biological activity and poor biological activity, and achieve good biocompatibility , improve the success rate, reduce the effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put the bismuth rod into the furnace body of the deposition chamber, the length of the bismuth rod is 8cm, and the diameter is 2.5mm. The magnesium raw material is placed in an evaporation chamber, and the chemical composition of the magnesium raw material is as follows: Cu content is 0.2%, Zn content is 1%, and the balance is Mg.

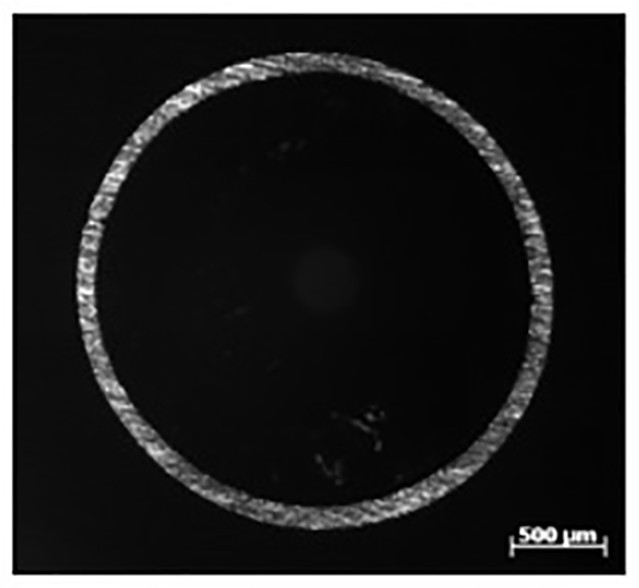

[0027] Example 1 uses coating deposition technology to uniformly deposit magnesium-based metal on the surface of bismuth rods, and then removes the bismuth rods by melting to obtain magnesium-based metal microtubes. The specific preparation steps are as follows: (1) the rod substrate Ultrasonic cleaning with anhydrous ethanol and deionized water in sequence, dried with dry nitrogen, placed on the rotating sample stage, and sent to the deposition chamber; (2) Put the magnesium alloy particles into the target position of the evaporation chamber, and pump the ultimate vacuum to 10 -4 Pa, and then filled with high-purity argon gas, and then evac...

Embodiment 2

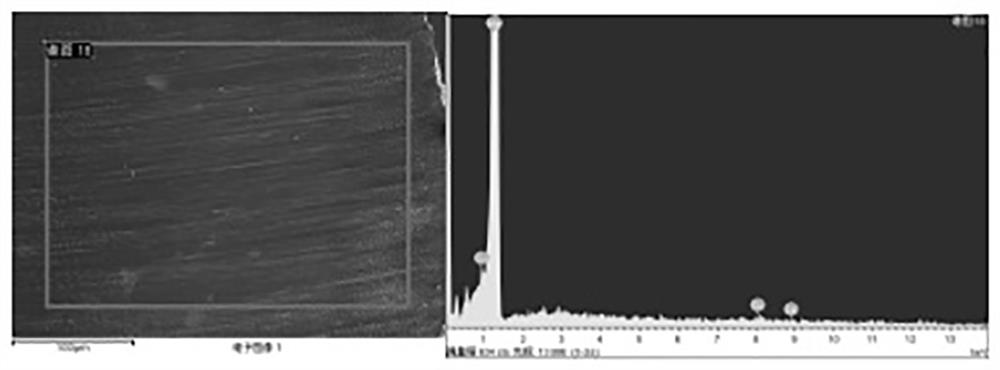

[0029] Put the indium rod into the furnace body of the deposition chamber, the length of the indium rod is 10 cm, and the diameter is 2.5 mm. The magnesium raw material is placed in the evaporation chamber. The chemical composition of the magnesium raw material is as follows: Cu content is 0.4%, Zn content is 2%, Sr content is 2%, and the balance is Mg. Set the sublimation temperature of the magnesium alloy to 450°C and the working pressure to 1×10 -2 Pa, the deposition temperature is 200°C, and the deposition time is 60 minutes. The sample is taken out after cooling with the furnace. -4 The indium rod was melted and removed by heating to 200°C under Pa vacuum to obtain a magnesium tube with a wall thickness of 200 µm and a tube degradation time of 2 weeks. The surface electron microscope characterization and elemental analysis results of the magnesium alloy microtubes are shown as follows: figure 2 shown. The tensile strength of the pipe is 190Mpa and the elongation is 10...

Embodiment 3

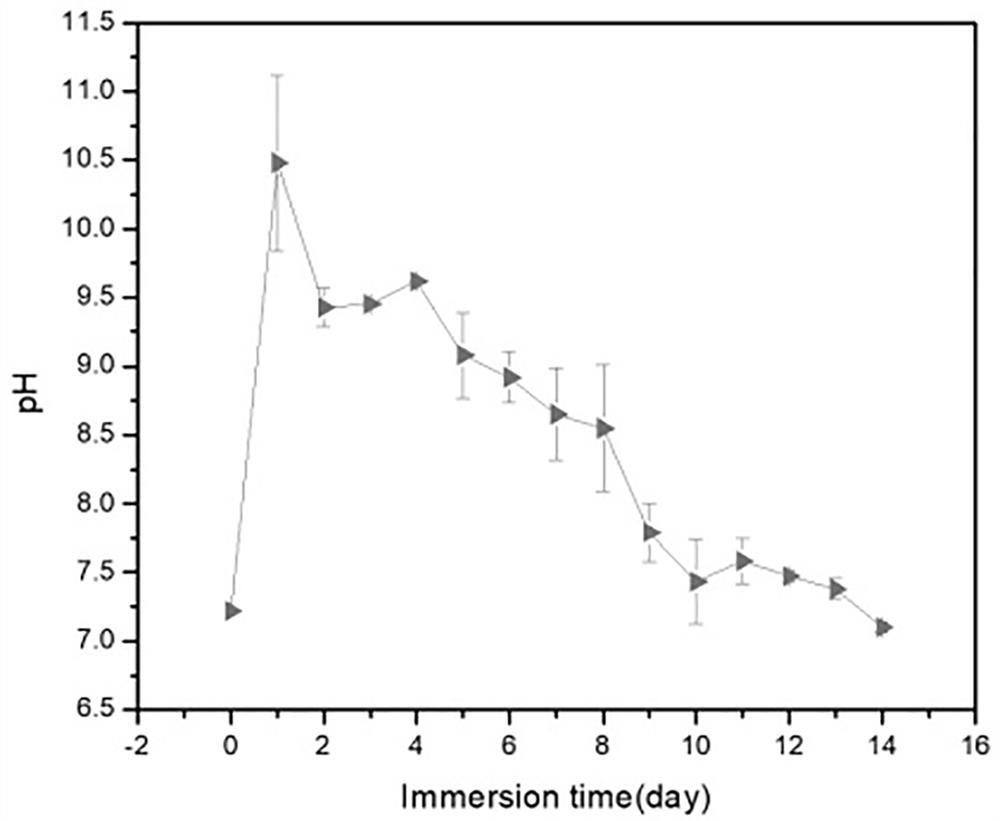

[0031] Put the tin rod into the furnace body of the deposition chamber, the length of the tin rod is 10cm, and the diameter is 3mm. The magnesium raw material is placed in the evaporation chamber. The chemical composition of the magnesium raw material is as follows: Cu content is 0.5%, Zn content is 3%, Sr content is 2%, and the balance is Mg. Set the sublimation temperature of the magnesium alloy to 450°C and the working pressure to 1×10 -2 Pa, the deposition temperature is 200°C, and the deposition time is 60 minutes. The sample is taken out after cooling with the furnace. -4 The indium rod was melted and removed by heating to 200°C under Pa vacuum to obtain a magnesium tube with a wall thickness of 200 µm and a tube degradation time of 2 weeks. The pipe is soaked in SBF, and its pH value change curve is as follows image 3 shown. The tensile strength of the pipe is 180Mpa and the elongation is 11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com