Method for synthesizing Janus nano particles by using Janus nano emulsion as template

A nanoparticle and nanoemulsion technology, which is applied in the preparation of microcapsule preparations and microspheres, can solve the problems of complex preparation process and achieve the effect of simple preparation process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) At room temperature, the oil phase (composed of oleic acid and silicone oil at a mass ratio of 1:1) and Tween surfactant at a mass ratio of 4:6 were mixed at a stirring speed of 700 rpm. Under the stirring speed, ultrapure water was added dropwise at a rate of 1.0 mL / h, and a molecular order with an amphiphilic bilayer structure, that is, lamellar liquid crystal, was formed through phase transition.

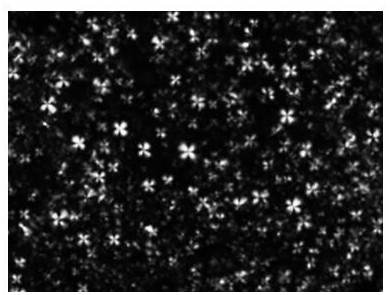

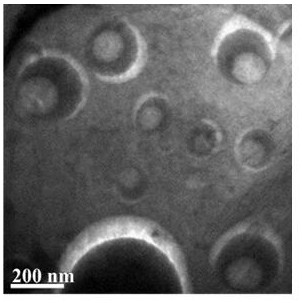

[0030] Authentication: from figure 1 It can be seen that during the preparation of the Janus nanoemulsion, a molecular order body with an amphiphilic bilayer structure is formed, and its polarized photo shows a typical cruciferous structure of lamellar liquid crystals. Depend on figure 2 It can be seen that the prepared lamellar liquid crystal does not flow after being inverted, which conforms to the macroscopic characteristics of lamellar liquid crystal.

[0031] 2) Continue to add ultrapure water to the above system until the content of ultrapure water accounts for...

Embodiment 2

[0034] 1) At room temperature, the oil phase (composed of oleic acid and silicone oil at a mass ratio of 1:1) and Tween surfactant at a mass ratio of 4:6, the same content of 4 wt% 1- Hydroxycyclohexylphenylacetone, different contents (0 wt%, 10 wt%, 20 wt%, 30 wt%, 40 wt%) of acrylate monomers were mixed at a stirring speed of 700 rpm. At this stirring speed, ultrapure water was added dropwise at a rate of 1.0 mL / h, and the final ultrapure water content was 90 wt% of the total mass of the emulsion.

[0035] Investigate the particle diameter of the prepared nanoemulsion as follows:

[0036] The particle size distribution of the Janus nanoemulsion before polymerization was measured by a ZEN3690 nanometer particle size analyzer from Malvern Company. The instrument uses a He-Ne laser light source with a wavelength of 632.8 nm. Before the test, the prepared nanoemulsion is diluted 50 times with ultrapure water to eliminate the multiple scattering phenomenon in the sample. The eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com