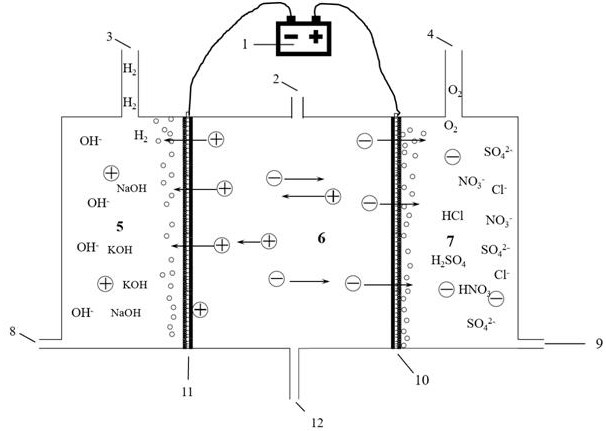

Method for selectively separating anions and cations in salt-containing wastewater by coupling electric field with composite electrofiltration membrane

A technology for compounding anion and salt-containing wastewater, applied in the field of salt-containing wastewater treatment and resource utilization, can solve the problems of poor ion selective separation effect, low membrane service life, low economic benefit, etc., achieves good anti-pollution performance, prevents mutual Diffusion, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, the method and device for selectively separating anions and cations in saline wastewater by using an electric field coupled composite electrofiltration membrane are used to carry out advanced treatment and resource utilization of pretreated high-salt wastewater from printing and dyeing. The specific content is as follows:

[0034] (1) Wash the 400-mesh porous stainless steel mesh (40cm×30cm) with 0.5mol / L sodium hydroxide solution, distilled water, 0.5mol / L hydrochloric acid solution and distilled water in sequence, and finally wash with absolute ethanol, dry it and place it in in the mold;

[0035] ZrO 2 30%, sintering aid CuO4%, pore-forming agent dextrin 20%, NaNbO 3 23%, KNbO 3 After the 23% is mixed evenly, take 250g of the mixed material and evenly cover the surface of the metal substrate, and press it into a porous ceramic layer under a pressure of 2430kN by hydraulic equipment; prepare 2 pieces;

[0036] (2) 12% catalytic hydrogen evolution c...

Embodiment 2

[0042] Example 2: In this example, the method and device for selectively separating anions and cations in saline wastewater by using electric field coupled composite electrofiltration membranes are used to treat and recycle phosphogypsum leachate. The specific contents are as follows:

[0043] (1) Wash the 600-mesh porous stainless steel mesh (40cm×30cm) with 0.5mol / L sodium hydroxide solution, distilled water, 0.5mol / L hydrochloric acid solution and distilled water in sequence, and finally wash it with absolute ethanol, dry it and place it in in the mold;

[0044] Take 15% ZnO of ceramic particles, 4% sintering additive CuO, 25% pore-forming agent dextrin, and 56% piezoelectric material bismuth sodium titanate and mix evenly. Take 250g of mixed powder and evenly cover the surface of the metal substrate. A porous ceramic layer with ferroelectricity is pressed under a pressure of 2570kN; 2 pieces are prepared;

[0045] (2) 10% catalytic hydrogen evolution catalyst FeCo / Cu (iro...

Embodiment 3

[0050] Example 3: In this example, the method and device for selectively separating anions and cations in saline wastewater by using an electric field coupled composite electric filtration membrane are used for desalination treatment and resource utilization of seawater. The specific content is as follows:

[0051] (1) Wash the 400-mesh porous aluminum alloy mesh (40cm×30cm) with 0.5mol / L sodium hydroxide solution, distilled water, 0.5mol / L hydrochloric acid solution and distilled water in sequence, and finally wash it with absolute ethanol, dry it and place it in the mold;

[0052] ZrO 2 30%, sintering aid SnO2 4%, pore-forming agent methylcellulose 20%, piezoelectric material NaNbO 3 46%, take 250g of uniformly mixed powder and evenly cover the surface of the metal substrate, press it under a pressure of 2430kN by hydraulic equipment to form a ferroelectric porous ceramic layer; prepare 2 pieces;

[0053] (2) 14% catalytic hydrogen evolution catalyst Ni 3 S 2 Nanorods, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com