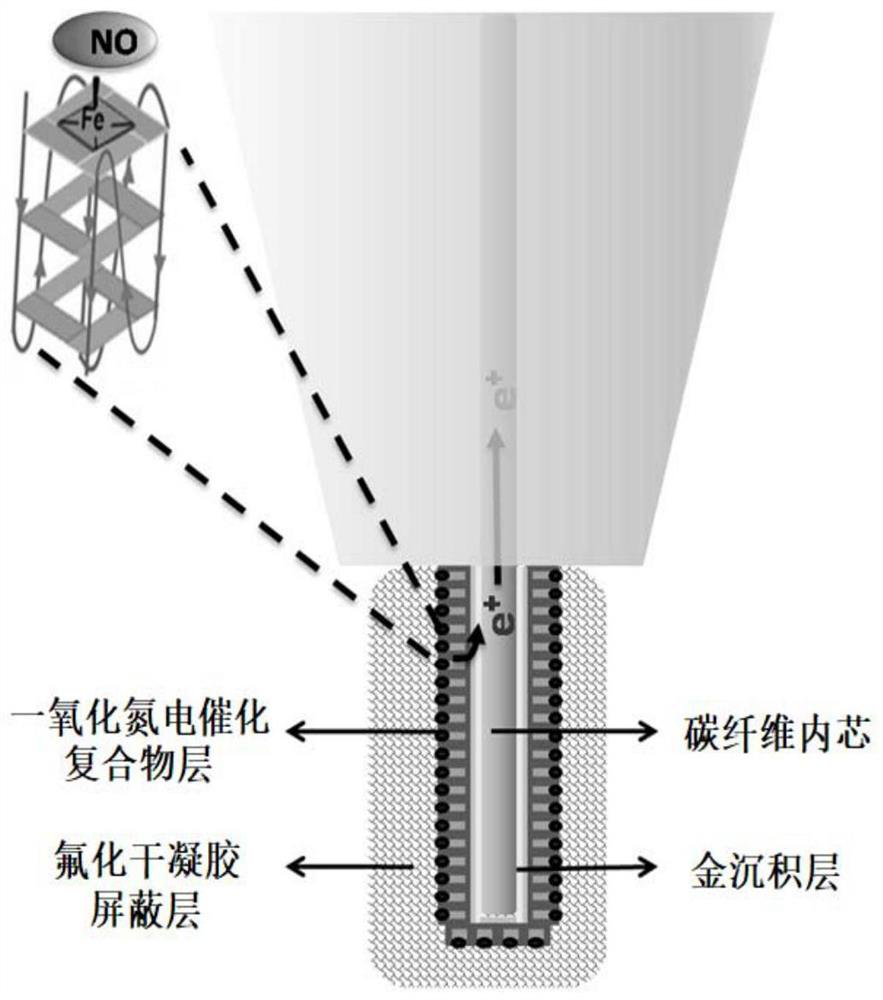

Nitric oxide electrochemical sensing microelectrode and preparation method and application thereof

A nitric oxide and micro-electrode technology, applied in the field of micro-electrodes, can solve the problem that the sensitivity and selectivity cannot meet the high-selectivity detection and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Cut a 15-20cm carbon fiber bundle and soak it in acetone overnight (just make sure the length can pass through the glass tube), and then put it on aluminum foil to dry. Sonicate in pure water for 10-20min, then draw the carbon fiber into a borosilicate glass capillary to prepare a carbon fiber electrode, and draw it to a fine tip with a glass wire drawing machine. The microelectrodes were cut and sealed in epoxy resin (Epon 828), then cured at 80 °C for 2 h and at 150 °C for 2 h, and finally copper wires were attached at the bottom of the carbon fibers to establish electrical contact. Place the treated electrode in 1mM K 3 [Fe(CN) 6 ], the cyclic voltammetry scan was carried out in the voltage range of -0.3 ~ 0.7V, the scan rate was 100mV / s, until the current was stable, and a carbon fiber microelectrode was obtained.

[0053] 2. Sonicate the tip of the carbon fiber microelectrode prepared in step (1) in ultrapure water, absolute ethanol, and ultrapure water for 5 ...

Embodiment 2

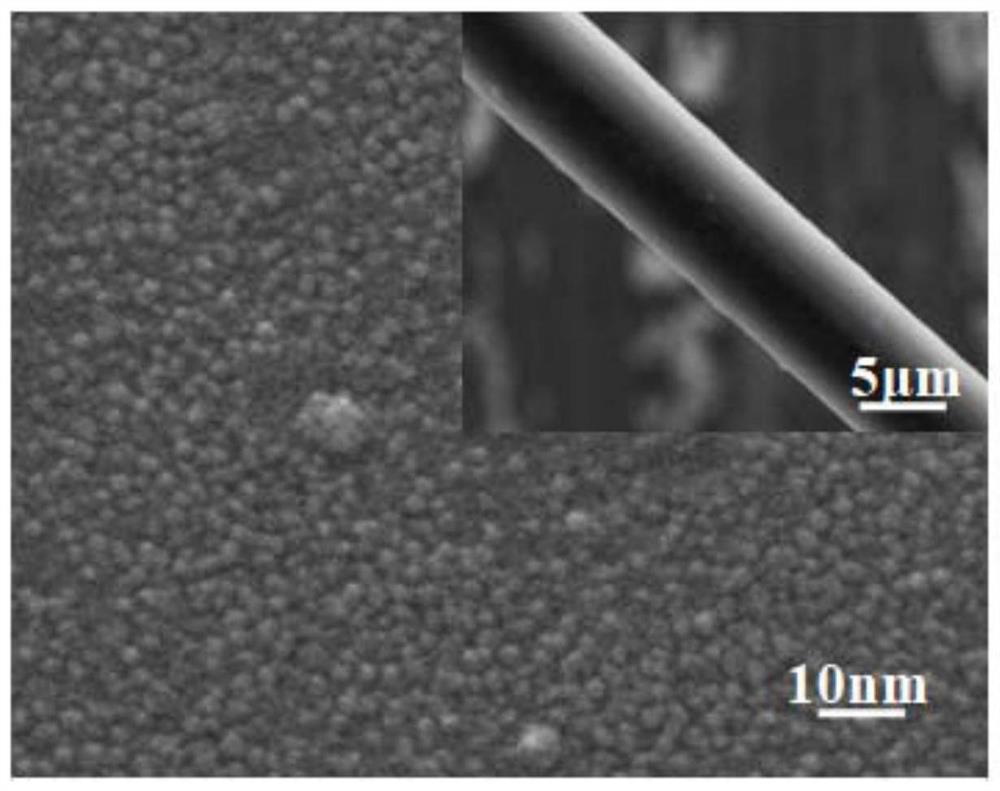

[0057] 1. The nitric oxide electrochemical sensing microelectrode prepared in Example 1 was scanned by an electron microscope, and its morphology was characterized under a scanning electron microscope as follows: figure 2 shown by figure 2 It can be seen that there are obvious spherical protrusions on the surface of the microelectrode at the nanoscale, indicating that simple gold was successfully deposited on the surface of the microelectrode, which improved the electrochemical activity of the electrode surface.

[0058] 2. The NO electrochemical sensing microelectrode detects the NO release process of macrophages:

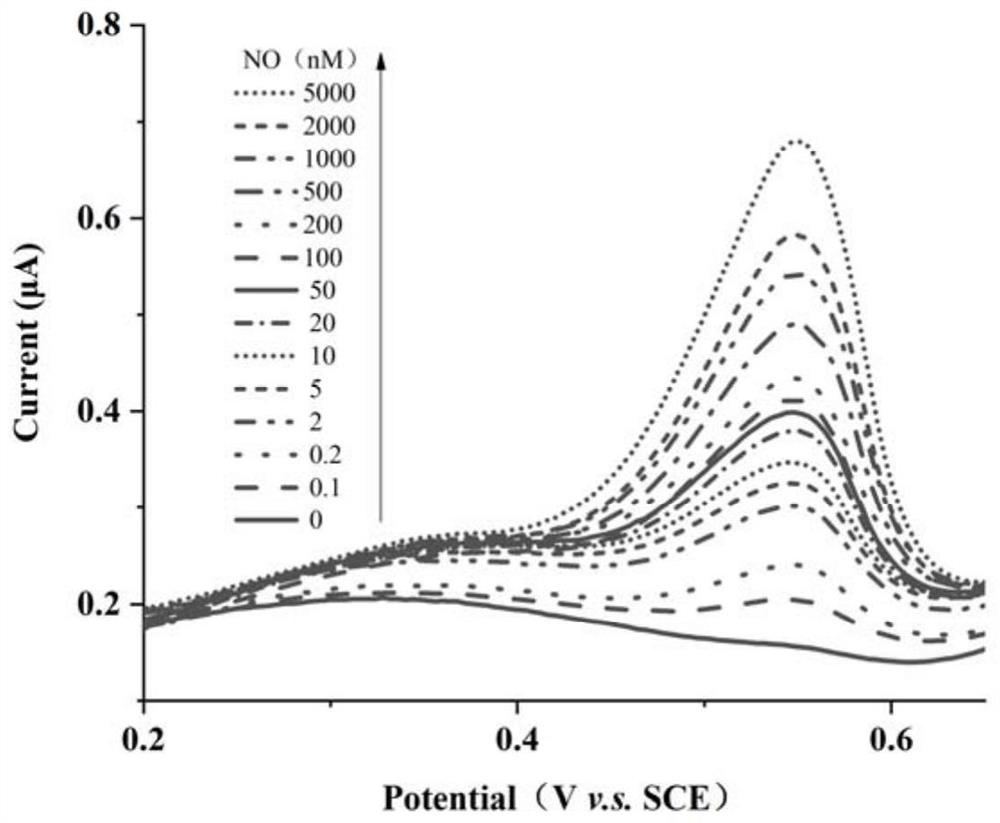

[0059] (1) Nitrogen was introduced into 0.1×PBS solution (pH=7.4) for 20-30min to remove oxygen, and the standard DEANONOate solution (50mM) was diluted and then added in a certain proportion to establish the final concentration gradient of NO (0.1nM, 0.2nM , 0.5nM, 1nM, 2nM, 5nM, 10nM, 20nM, 50nM, 100nM, 200nM, 500nM, 1000nM, 2000nM, 5000nM). Utilize a three-...

Embodiment 3

[0064] Example 3 adopts the method of Example 1, the difference is that in step (3), the microelectrode is incubated in the DNA modification buffer for 12 hours at room temperature, and the heme Hemin and the above-mentioned electrode are combined in the binding buffer (Binding buffer) Incubate at room temperature for 40min. In step (3), the G4-DNA concentration in the DNA modification buffer is 10 μM, and the Hemin concentration in the binding buffer is 0.2 mM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com