Active-oxygen-responsive degradable polyurethane heart patch for myocardial infarction repair and preparation method thereof

A technology of myocardial infarction and polyurethane, which is applied in medical science, prosthetics, tissue regeneration, etc., can solve the problems of lack of functionality, and achieve the effect of simple preparation method, easy realization, and repair of heart function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Active oxygen responsive degradable unsaturated polyurethane material (PFTU-1:1), including a soft segment and a hard segment, the soft segments are respectively polytrimethylene fumarate (PPF) and polyketone with a number average molecular weight of 1000 Thiol (PTK), the molar ratio of the two feeds is 1:1; the hard segment is an aliphatic diisocyanate such as hexamethylene diisocyanate (HDI) and a small molecule diamine chain extender such as dimethyl lysine (Lys-OMe).

[0032]Take 1.000g of PPF and 1.000g of PTK with a number average molecular weight of 1000 and add them to two dry two-necked flasks respectively, and calculate the number of hydroxyl moles of PPF and the number of mercapto groups of PTK to be 1.000mmol and 1.000mmol respectively. Distilled under pressure for 1h to remove residual moisture, and nitrogen gas was introduced. After cooling down to 70°C, add 10 mL of anhydrous 1,4-dioxane solvent to the PPF bottle for dissolution, then add 288 μL HDI and ...

Embodiment 2

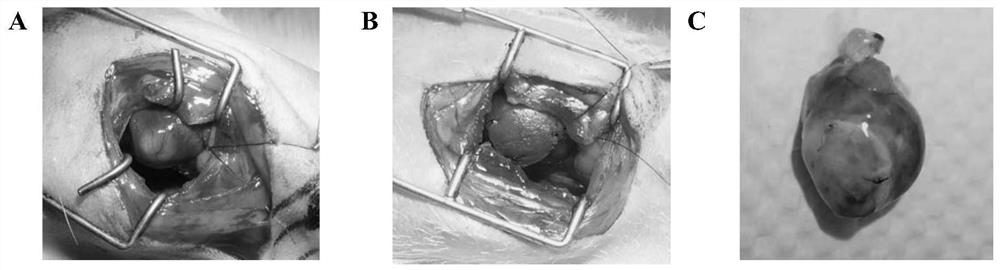

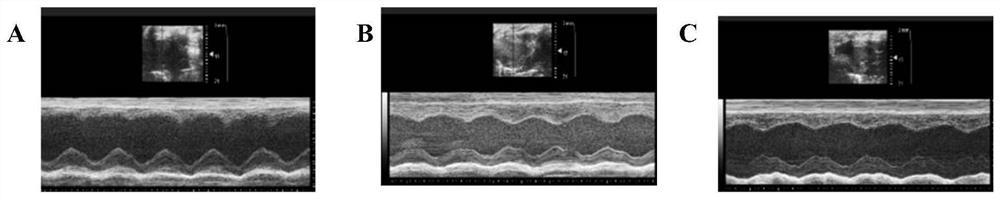

[0034] Dissolve 1.0 g of reactive oxygen-responsive degradable unsaturated polyurethane material (PFTU) in 10 mL of tetrahydrofuran, pour it into a polytetrafluoroethylene mold, and evaporate it in air at room temperature for 48 hours, then dry it in vacuum at 37°C for 48 hours to completely remove the solvent , to obtain active oxygen responsive degradable polyurethane heart patch. The heart patch tensile strength that this pouring method obtains is 7.2MPa, and tensile modulus is 17.9MPa, and elongation at break is 760%; H 2 o 2 After 28 days of degradation in solution, the mass loss was 12.41%. The active oxygen-responsive degradable polyurethane heart patch obtained by this casting method is used to restore cardiac function after myocardial infarction.

Embodiment 3

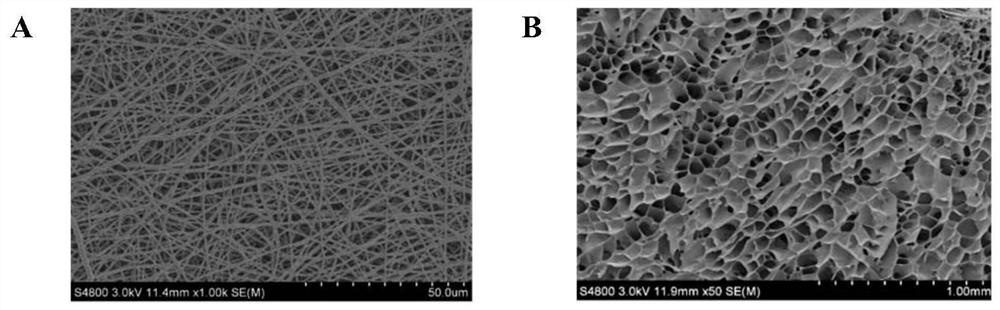

[0036] 0.75 g of active oxygen-responsive degradable polyurethane was dissolved in 5 mL of hexafluoroisopropanol solution, wherein the mass concentration of polyurethane obtained was 15%, and the nanofiber membrane was prepared by spinning with an electrospinning device. Electrospinning parameters are: spinning temperature is 25-30°C, humidity is 30-40%, spinning voltage is 15kV, liquid supply speed is 1mL / h, roller receiving distance is 10cm, receiving length is 5cm, rotating speed is 200rad / min. The prepared nanofiber membrane was dried in a vacuum oven at 25° C. for 24 hours. A random electrospun fiber membrane was obtained with a fiber diameter of 700 nm and a thickness of 0.06 mm. The polyurethane electrospun fiber membrane heart patch has good mechanical properties, the tensile strength is 10MPa, and the tensile strain is 400%. This electrospinning method was used to obtain active oxygen responsive degradable polyurethane electrospun fiber heart patch for repairing car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com