Tellurium-manganese-cadmium nano-powder and preparation method thereof

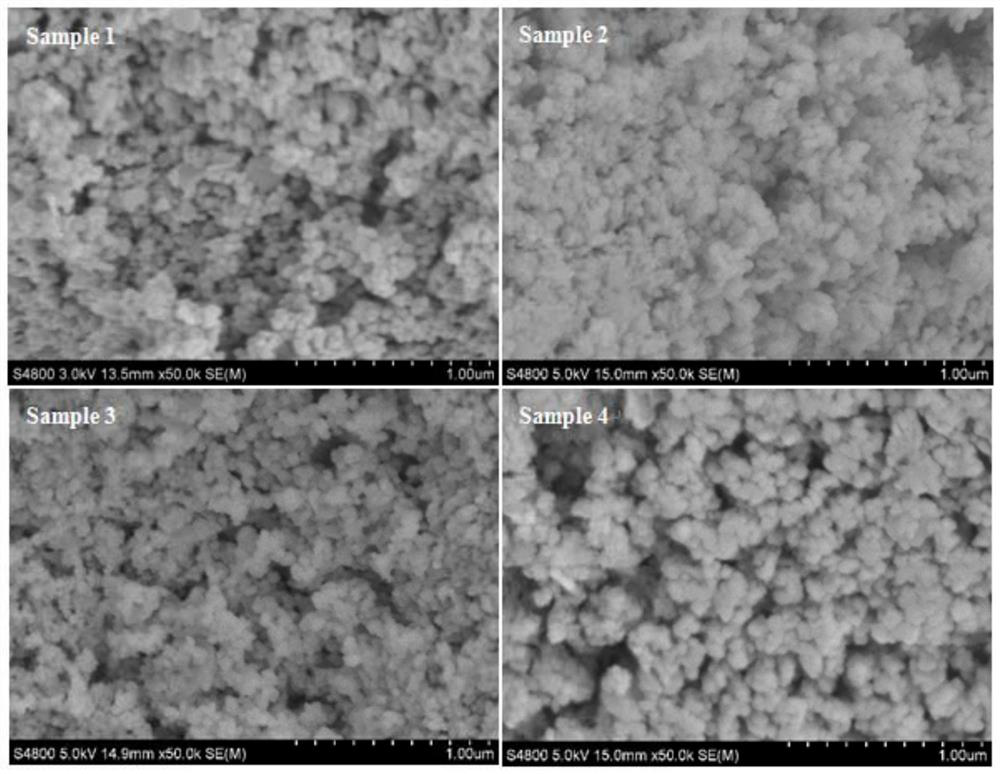

A nano-powder, cadmium-manganese-telluride technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the complex preparation process, quantum dots contain impurities, and are not purely equal, and achieve simple operation and powder size Good uniformity and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

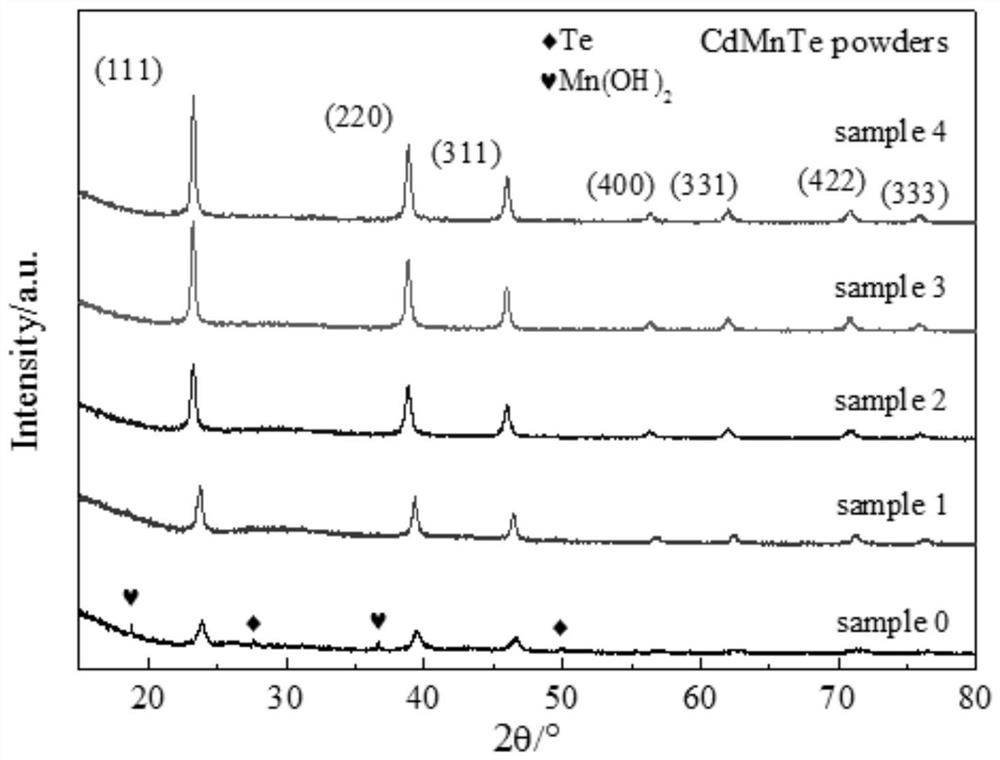

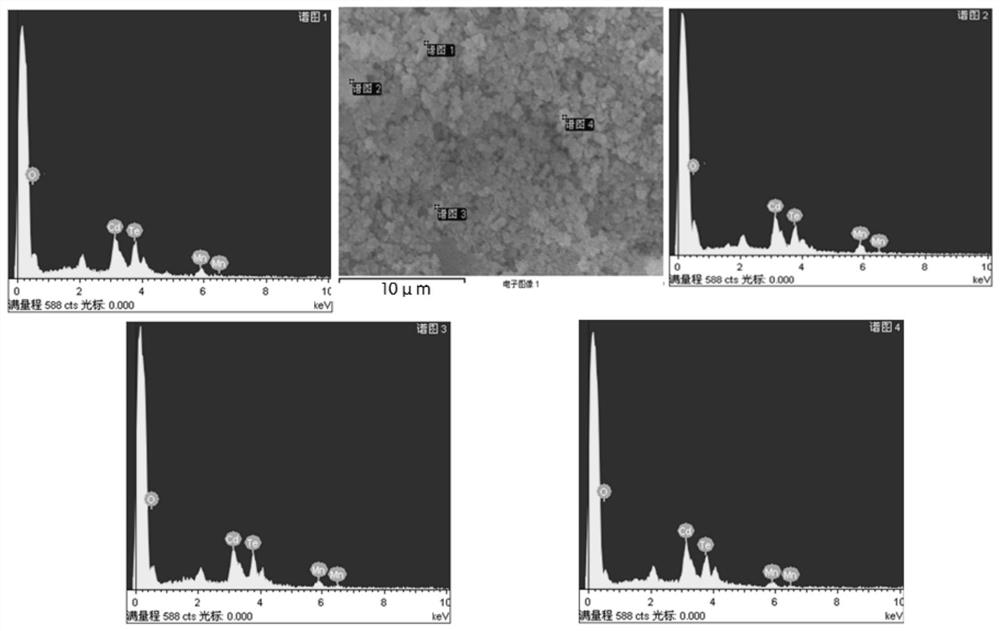

[0030] In the preparation method of the cadmium manganese telluride nano-powder of the present invention, the cadmium manganese telluride nano-powder has a pure-phase sphalerite structure, cadmium chloride and manganese chloride are used as the cadmium source and the manganese source, and sodium tellurite is the tellurium source. Sodium citrate and mercaptopropionic acid are used as stabilizers and protective agents, sodium borohydride is used as a reducing agent, a pH regulator is used to control the solution to be strongly alkaline, and cadmium manganese telluride nanometer powder is obtained through hydrothermal reaction. CdCl 2 , MnCl 2 and Na 2 TeO 3 (or K 2 TeO 3 ) molecule molar ratio, or the molar ratio of Cd, Mn and Te atoms, the molar ratio of Cd, Mn and Te in cadmium salt, manganese salt and tellurite is: 1:(0.1~0.5):(1.1~1.5 ); the molar ratio of cadmium salt, sodium citrate and mercaptopropionic acid is: 1:(0.1~1):(1~5) refers to CdCl 2 (cadmium salt), Na 3...

Embodiment 1

[0037]According to the molar ratio of cadmium source and manganese source as 1:0.5, weigh 0.4568g of cadmium chloride and 0.1980g of manganese chloride, add 30ml of deionized water to form a mixed solution, and magnetically stir; The molar ratio is 1:0.1, then weigh 0.0664g of sodium citrate, and add it to the solution; then add 10 drops of mercaptopropionic acid with a volume fraction of 98% to form a suspension, and stir it magnetically for 10 minutes; The molar ratio of acid salt is 1:1.5, weigh 0.6645g sodium tellurite and dissolve it with deionized water (dissolved amount), add it under the condition of magnetic stirring, use pH adjuster (4mol / L sodium hydroxide solution) Adjust the pH value to 14; then according to the molar ratio of cadmium source and sodium borohydride as 1:18, weigh 1.3617g of sodium borohydride and dissolve it in ethanol, and add it under the same condition of magnetic stirring to finally obtain cadmium manganese telluride water Heat reaction precurs...

Embodiment 2

[0040] According to the molar ratio of cadmium source and manganese source as 1:0.5, weigh 0.2284g of cadmium chloride and 0.0990g of manganese chloride, add 30ml of deionized water to form a mixed solution, and magnetically stir; The molar ratio is 1:0.1, then weigh 0.0333g of sodium citrate, and add it to the solution; then add 10 drops of mercaptopropionic acid with a volume fraction of 98% to form a suspension, and stir it magnetically for 10 minutes; The molar ratio of acid salt is 1:1.5, weigh 0.3324g sodium tellurite and dissolve it with deionized water (dissolved amount), add it under the condition of magnetic stirring, use pH adjuster (4mol / L sodium hydroxide solution) Adjust the pH value to 14; then according to the molar ratio of cadmium source and sodium borohydride as 1:18, weigh 0.6807g of sodium borohydride and dissolve it in ethanol, and add it under the same condition of magnetic stirring to finally obtain cadmium manganese telluride water Heat reaction precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com