Biological aviation kerosene component oil and preparation method thereof

A technology of component oil and aviation kerosene, which is applied in the field of bio-jet kerosene component oil and its preparation, can solve the problems of catalyst deactivation and many side reactions, achieve high conversion rate and yield, less side reactions, and realize The effect of green sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

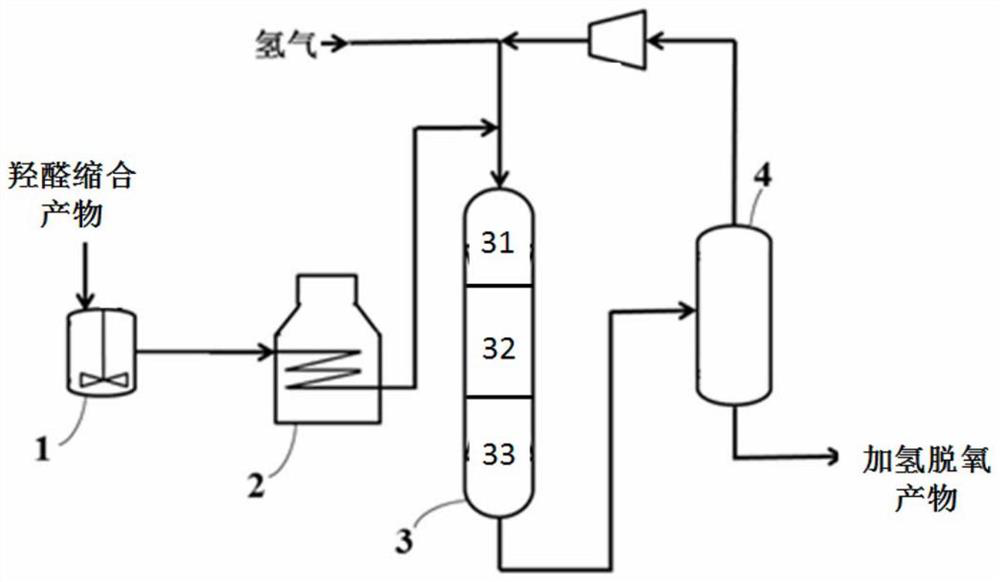

[0037] The present invention provides a method of preparation of bioained coal components, including:

[0038] S1: The lignocellulose basedehyde compound and the carbonyl compound are hydroxal condensation reaction, resulting in c 8 ~ C 16 Long chain contains oxygen compound;

[0039] S2: Will C 8 ~ C 16 The long chain contains oxygenate in the first reaction zone that is sent to the reactor under a reactive solvent condition.

[0040] S3: Hydrogenated product is hydrode oxygen by hydrogenation by the second reaction zone of the reactor, resulting in c 8 ~ C 16 Long paraffin;

[0041] S4: C 8 ~ C 16 Long chain alkane is isomerized, and the bioained coal component oil is obtained after fractionation;

[0042] Wherein, the temperature of the first reaction zone is 50 ° C to 200 ° C, and the temperature of the second reaction zone is greater than the temperature of the first reaction zone.

[0043] According to the present invention, there is still a parallel reaction in the process of...

preparation example 1

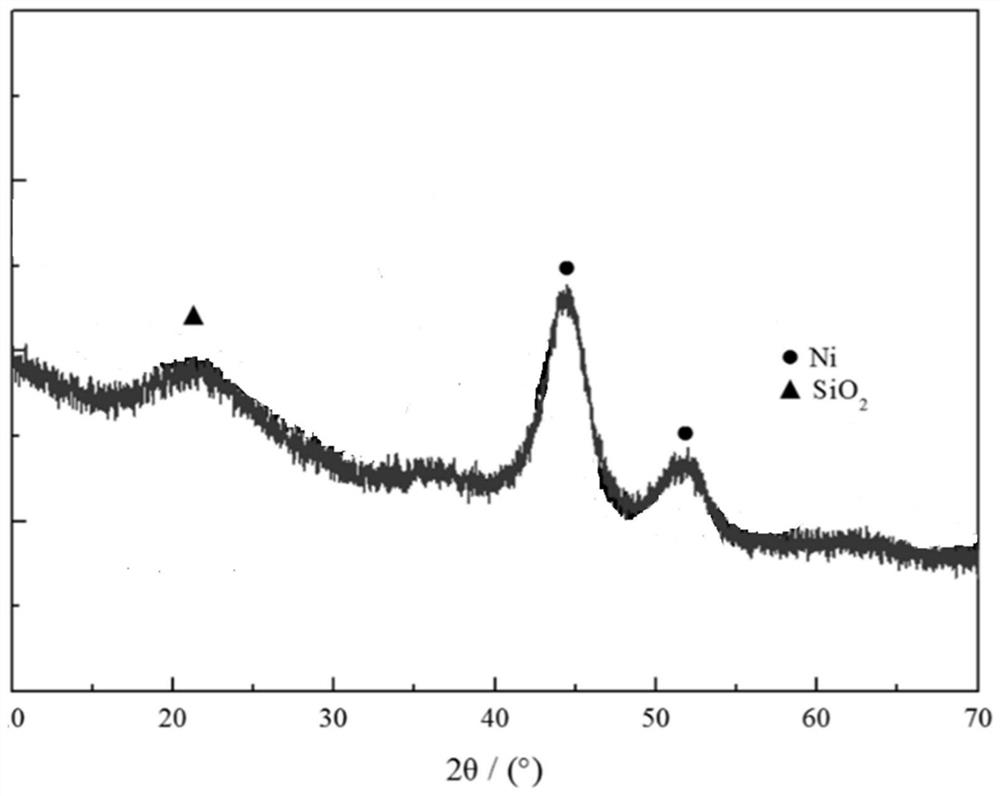

[0075] This formulation is used to illustrate the preparation method of the hydrocarbon saturation catalyst of the present invention.

[0076] Tell 290G Ni (NO 3 ) 2 · 6h 2 O and 1600 g of silica sol (solid content of 30%) are dissolved in deionized water, configured to include 1.0 mol / L of sodium hydroxide solution B by Ni ion mean; to maintain a solution in agitation, The B solution was slowly added to the A solution until the system pH was 10.5. After the dropwise addition, stirring was continued for 1 h, then stop stirring, standing for aging 8 h. The precipitate was then filtered, washed to neutral, and the filter cake was dried at 110 ° C in the blast drying tank, and then baked at 500 ° C in the muffle furnace for 3 h.

[0077] 160.0 g of a balanced product, 140.0 g of silica sol (solid content of 30%), 1.0 g of citric acid, 10.0 g of Tianjing powder and 40.0 g of water mixed, repeatedly kneaded, extruded into a diameter of 1.8 mm The cylindrical thin strip, a strip of a l...

preparation example 2

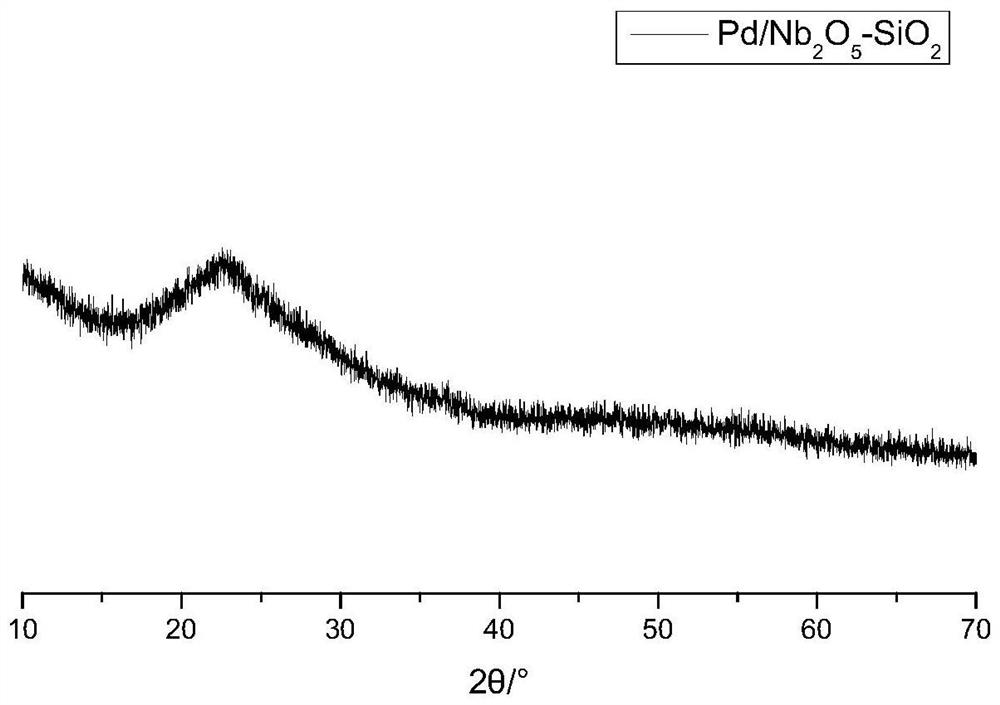

[0080] This system is used to illustrate the preparation method of the hydrode oxygenation catalyst of the present invention.

[0081] It was configured 0.5 mol / L citrate solution A, weighing 14.6 g of orthosilicate (TEOS) to obtain a mixed liquid B in a solution of 7.9 ml A, then citric acid (with TEOS weight ratio of 0.2: 1) The solution B was added to the deionized water, stirred to form a sol, and then stirred to form a gel, aging 2h. The above gel was dried at 100 ° C at 100 ° C in the blast drying tank, and then baked at 600 ° C at the muffle to obtain a white solid.

[0082] PDCL with PD content is 5g / L 2 The solution C, shifted 3 ml solution C, configured to impregnate the solution D, at an equal volume impregnation method to 2 g of the above-mentioned white solid and stir well, and then placed in a blast dryer at 100 ° C for 12 h; The yellow solid was baked at 500 ° C in the muffle furnace to obtain a yellow solid at 200 ° C at 200 ° C in the hydrogen gas to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com