Mesoporous metal oxide hollow material with high specific surface area and preparation method thereof

A high specific surface area, mesoporous silica technology, used in the preparation/processing of rare earth metal compounds, rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, etc., can solve the problem of small pore volume. , low specific surface area of mesoporous metal oxides, etc., to achieve the effects of large pore volume, simple preparation method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

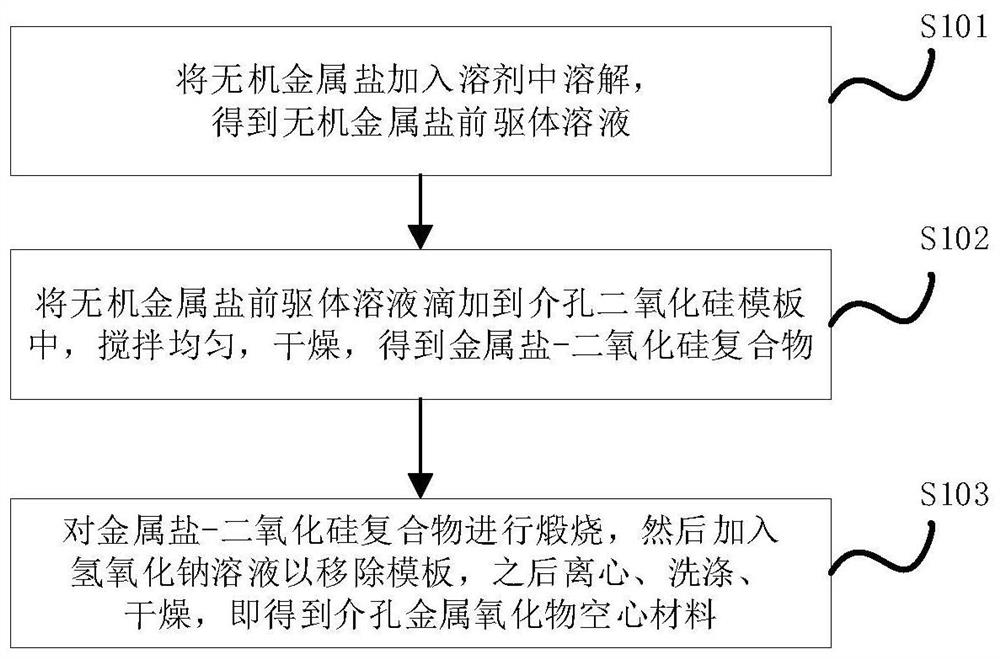

[0042] figure 1 It is a schematic flow chart of the preparation method of the mesoporous metal oxide hollow material with high specific surface area provided by the embodiment of the present application, refer to figure 1 , the preparation method provided by the embodiment of the present application comprises the following steps:

[0043] Step S101, configure the inorganic metal salt precursor solution: add the inorganic metal salt into the solvent to dissolve, and obtain a uniform inorganic metal salt precursor solution; the inorganic metal salt is selected from ferric nitrate, copper nitrate, manganese nitrate, cerium nitrate, nickel nitrate, nitric acid A mixture of any one or more of cobalt, chromium nitrate, phosphotungstic acid or phosphomolybdic acid; the solvent is any one or more of water, ethanol, methanol, ethylene glycol, glycerol or tetrahydrofuran , the solvent can also be selected from any one or a combination of hydrochloric acid, acetic acid or nitric acid; ...

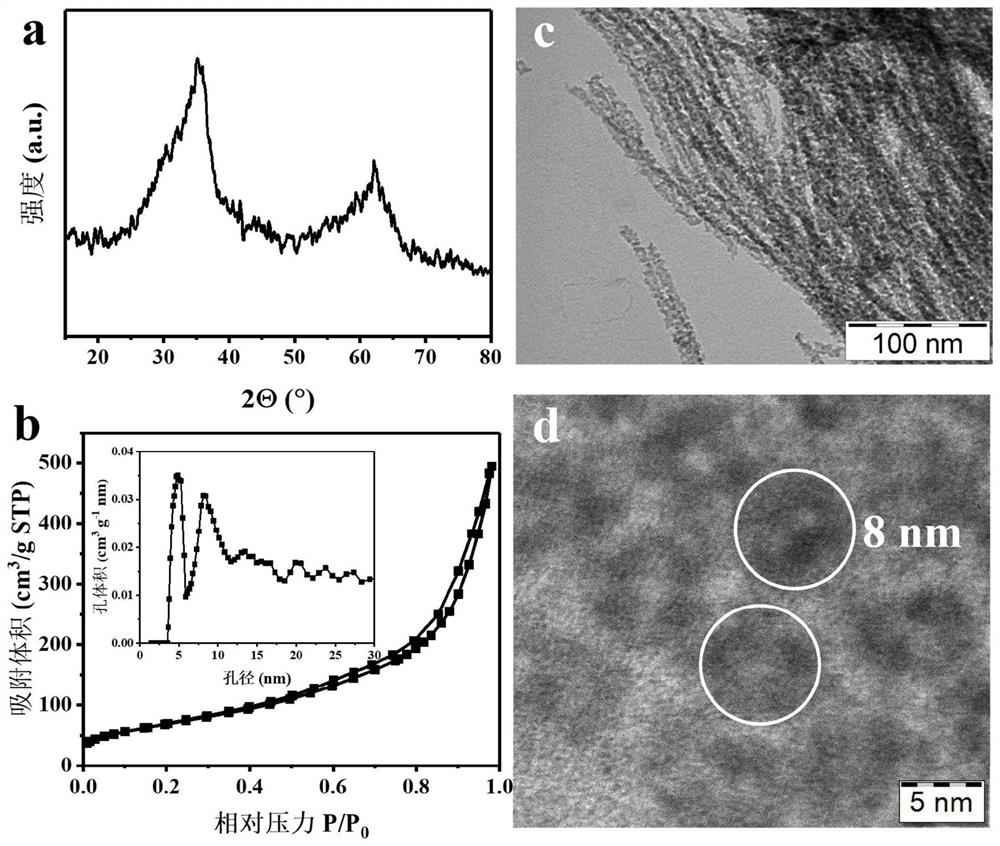

Embodiment 1

[0055] Embodiment 1 of the present application provides a method for preparing a mesoporous metal oxide hollow material, comprising the following steps:

[0056] Step S101, dissolving 7.5g of ferric nitrate in 2.5g of ethanol-ethylene glycol aqueous solution, stirring and dissolving to form a transparent ferric nitrate precursor solution; in ethanol-ethylene glycol aqueous solution, the volume ratio of ethanol, ethylene glycol and water is 1 :1:1;

[0057] In step S102, 0.20 g of ferric nitrate precursor solution is added dropwise to 0.5 g of SBA-15-OH template in 3 times, fully stirred for 10 minutes after each drop, and after the drop is completed, the obtained reaction system is sealed, and then standing in an oven at 70°C for 12 hours, and then standing in an oven at 90°C for 24 hours to obtain a metal salt-silicon dioxide composite;

[0058] Step S103, transfer the metal salt-silicon dioxide composite to a muffle furnace, raise the muffle furnace from room temperature to...

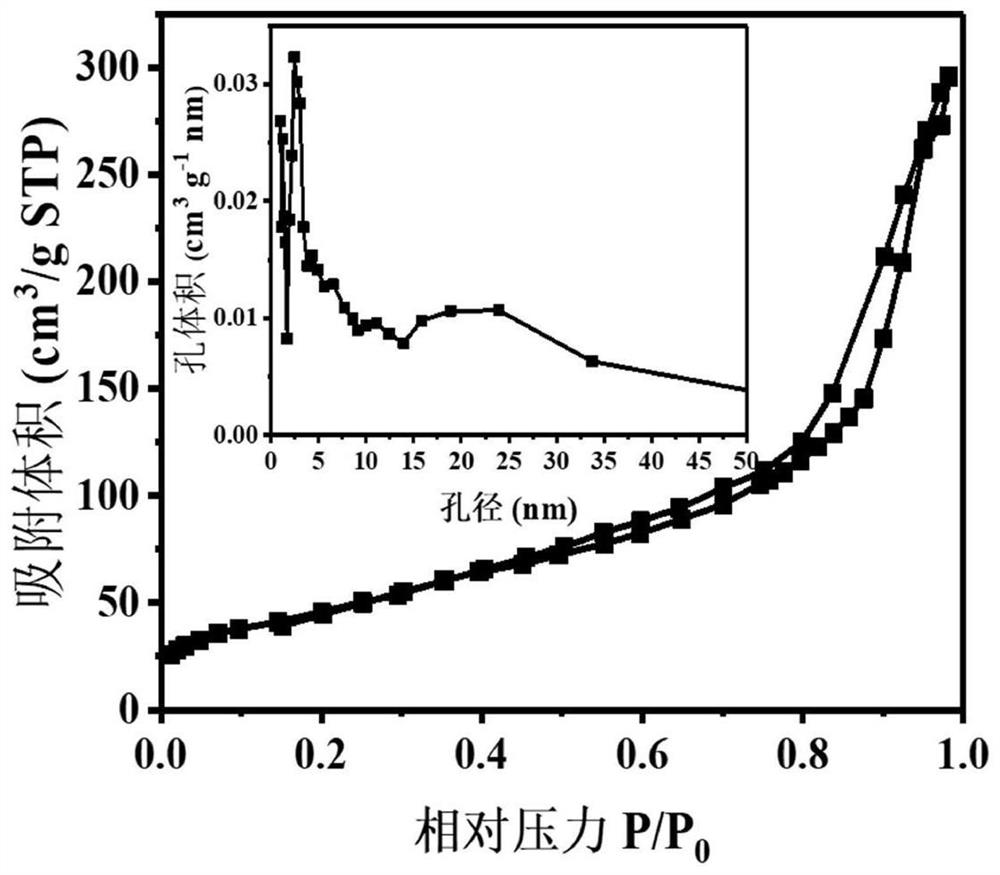

Embodiment 2

[0062] Embodiment 2 of the present application provides a method for preparing a mesoporous metal oxide hollow material, comprising the following steps:

[0063] Step S101, dissolving 3.4g of cerium nitrate in 1.6g of hydrochloric acid solution with a concentration of 1.07mol / L, stirring and dissolving to form a transparent cerium nitrate precursor solution;

[0064] Step S102, weighing 0.38g of cerium nitrate precursor solution and adding dropwise to 0.5gSBA-15-OH template in 3 times, fully stirring for 10 minutes after each dropwise addition, after the dropwise addition, the obtained reaction system was sealed, and then First stand in an oven at 90°C for 20 hours, and then in an oven at 120°C for 12 hours to obtain a metal salt-silicon dioxide composite;

[0065] Step S103, transfer the metal salt-silicon dioxide composite to a tube furnace, raise the temperature from room temperature to 450°C at a rate of 3°C / min in an ammonia-nitrogen mixed gas atmosphere, and calcinate for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com