Two-dimensional catalytic material and preparation and application thereof

A technology of catalytic materials and two-dimensional materials, which is applied in the field of two-dimensional catalytic materials and their preparation and application, can solve the problems of difficult material recovery and fragility, achieve convenient separation and recovery, avoid powderization, good mechanical properties and structure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

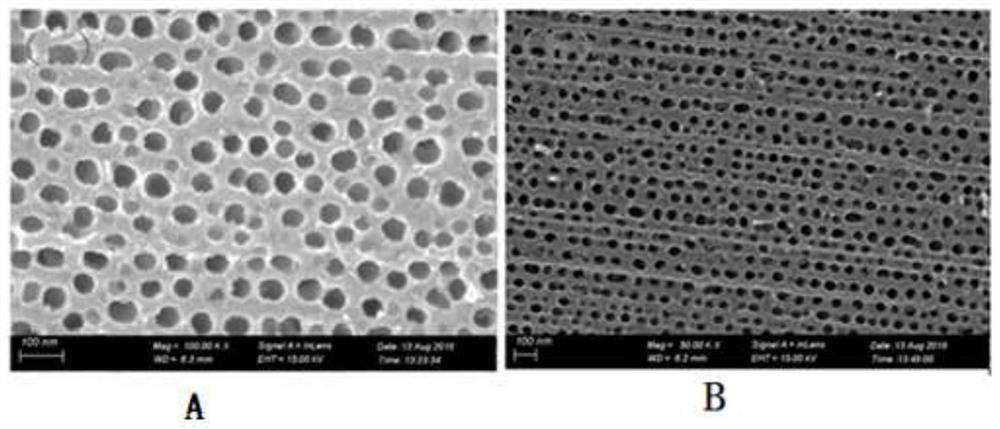

[0132] Fabrication of hole arrays on the surface of transition metal foils

[0133] Any existing technology can be used to form a hole array (nano-scale and / or micron-scale pores) on the surface of the transition metal foil, for example, the publication (announcement) number: CN103402908B publication (announcement) date: 2016.08.31 patent The document discloses methods for producing highly ordered nanopillar or nanopore structures over large areas, such as anodization.

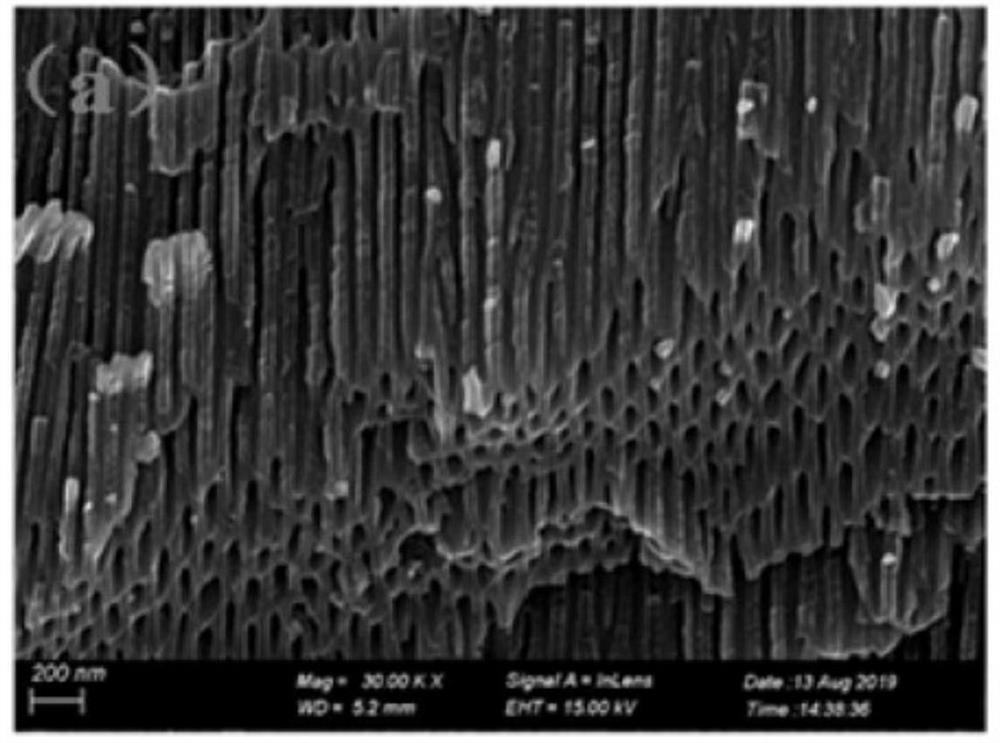

[0134] In some embodiments, after the "transition metal foil with concave-convex stripes on the surface" is treated by a conventional anodic oxidation method, nanoscale and / or micron array of apertures.

[0135] In some embodiments, the transition metal foil is used as the anode to connect to the positive electrode of the external power supply and placed in the electrolyte solution. The cathode can be selected from Pt sheet, titanium plate, stainless steel, stone grinding rod, etc., which are not easy to reac...

Embodiment 1

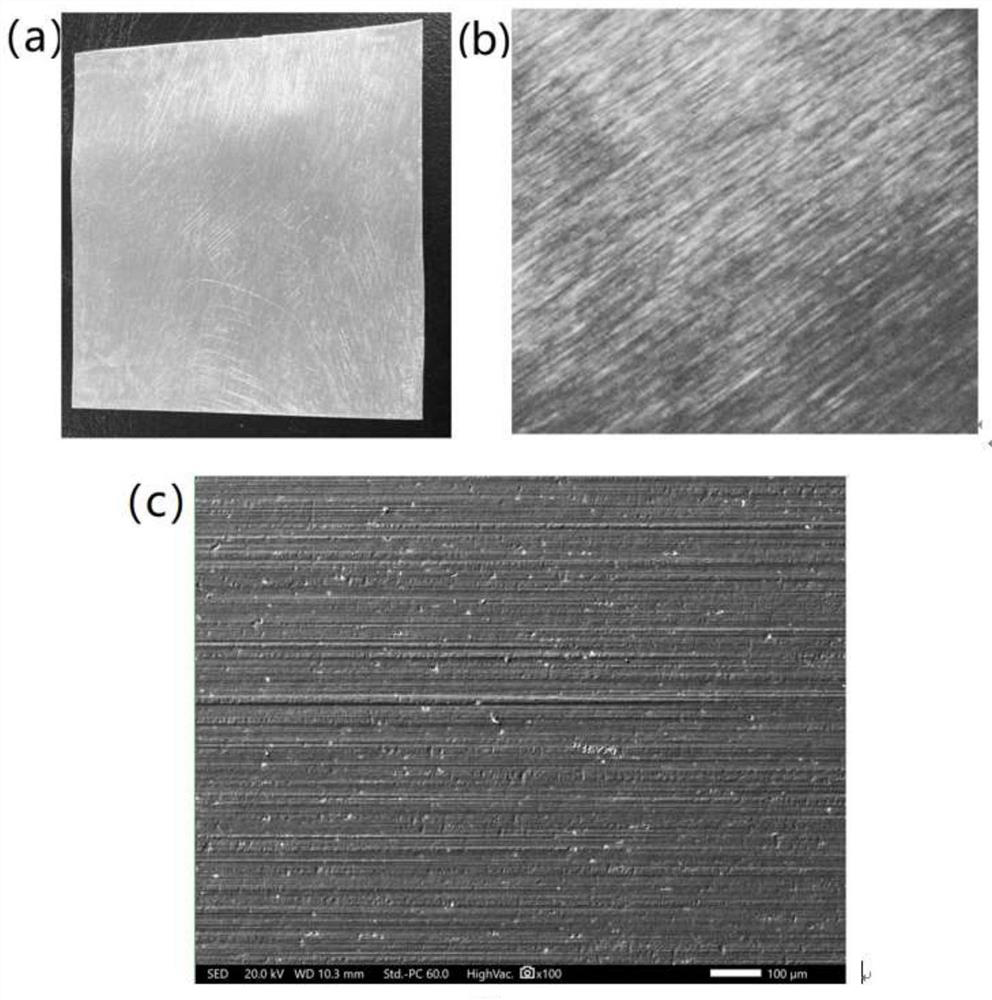

[0143] In this example, an aluminum foil with a thickness of 200 μm is selected as the basic material for the preparation of a two-dimensional base material. The surface before polishing is as follows figure 1 a; the specific steps are as follows:

[0144] 1) Pretreatment: The aluminum foil (upper and lower surfaces) is pretreated by degreasing, grinding, wire drawing, and washing. Acetone solution is used for degreasing, and ethanol and deionized water are used for cleaning. After completion, dry it in an oven at 50°C for later use. The comparison picture after treatment is shown in 1b;

[0145] 2) Anodizing: use titanium plate as cathode, pretreated aluminum foil as anode, 50g / L oxalic acid solution (take 300ml) as corrosion electrolyte, and the reaction of corrosion electrolyte in the process of anodization The container has been placed in an ice-water bath, and the temperature is kept at 10±1°C; during anodic oxidation treatment, the distance between the positive and neg...

Embodiment 2

[0159] In this embodiment, a two-dimensional transition metal tin foil with a thickness of 300 μm and concave-convex stripes (the stripe width is about 60nm, the stripe depth is 4nm, and the stripe spacing is 60nm) is selected as the base material for the preparation of the base material. The steps are as follows:

[0160]1) Pretreatment: The two sides of the tin foil are pretreated by several steps of degreasing, grinding, wire drawing and water washing. The degreasing adopts acetone solution, and the cleaning adopts ethanol and deionized water respectively. After completion, dry it in a 50°C oven for later use;

[0161] 2) Anodizing: take the titanium plate as the cathode, take the pretreated tin foil as the anode, take 150g / L sulfuric acid solution (take 300ml) as the corrosion electrolyte, and install the reaction vessel of the corrosion electrolyte during the anodization process Always put it in an ice-water bath and keep the temperature at 10±1℃; during anodization, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com