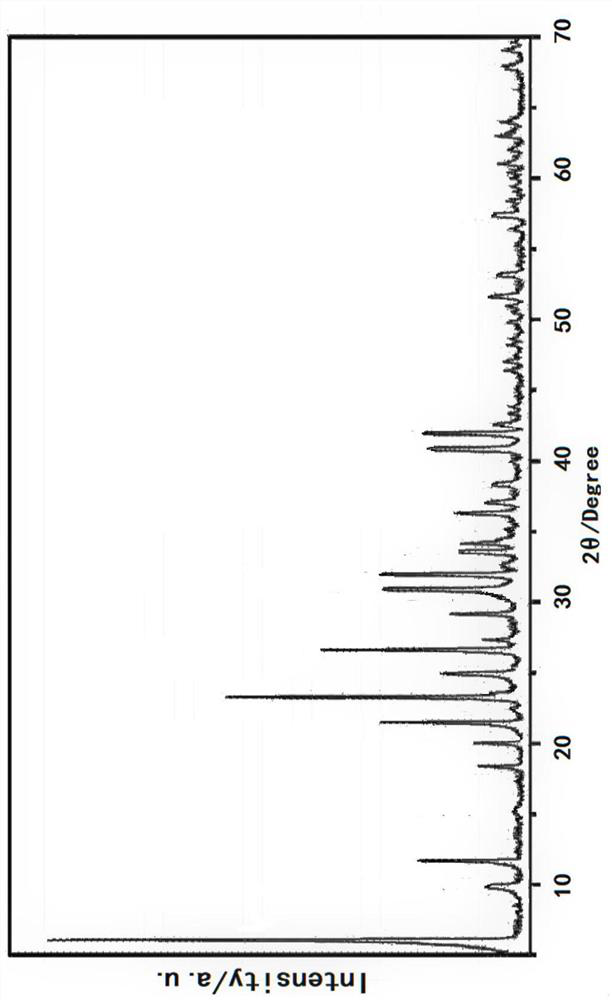

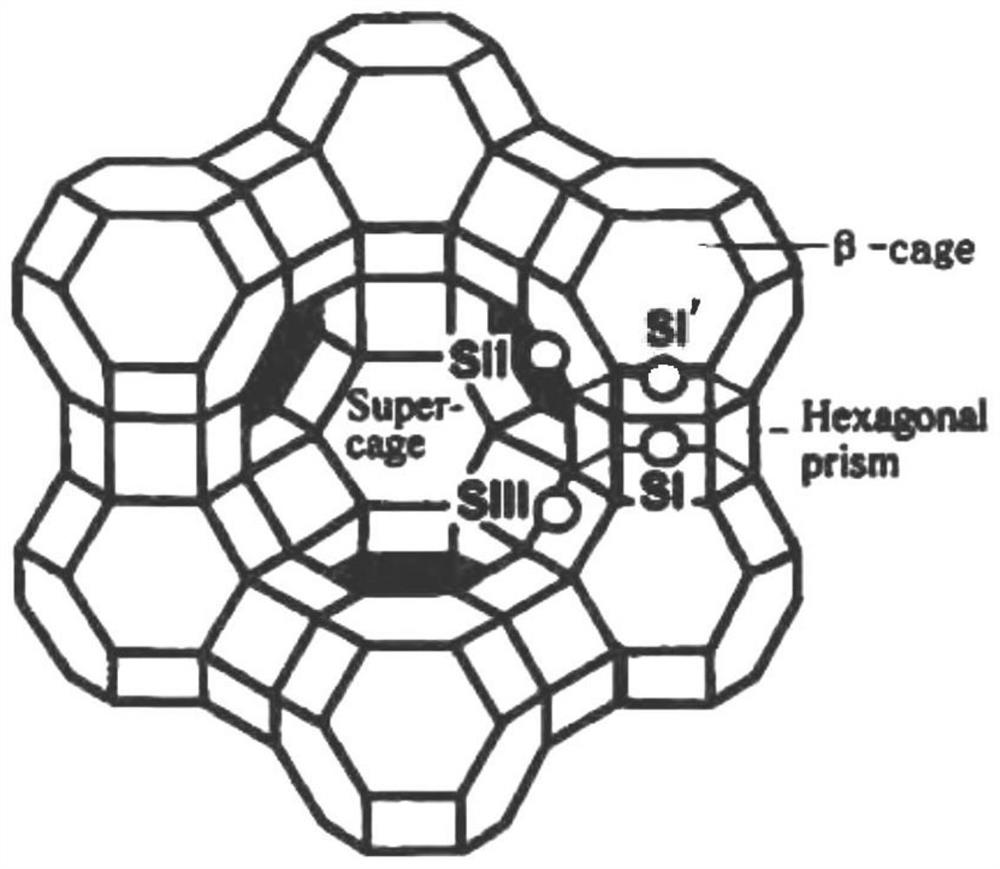

Rare earth-containing Li-LSX zeolite as well as preparation method and application thereof

A zeolite and rare earth technology, applied in the chemical industry, can solve the problems of poor oxygen adsorption performance, low lithium exchange degree, high cost, etc., and achieve the effects of reduced condition control requirements, simple and easy-to-control preparation process, and reduced consumption and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] This example is used to illustrate the implementation process of the preparation method of the present invention and the prepared rare earth-containing Li-LSX zeolite.

[0100] In 0.6 liters of deionized water, add 0.4 liters of water glass (industrial grade, SiO 2 =250g / L, modulus 3.2, Leshan Branch of Runhe Catalyst Co., Ltd.) and 0.5 liters of low alkalinity sodium metaaluminate (industrial grade, Al 2 o 3 = 100 g / L, Na 2 O=150 g / L, same as above), after uniform stirring, static crystallization at 95° C. for 6 hours.

[0101] After filtration, exchange with 4wt% cerium nitrate solution (prepared by industrial grade cerium nitrate, as above) at 85°C for 1 hour at a liquid / solid ratio of 5:1, dry and roast at 450°C for 1 hour, and then Next exchange once, the filtrate is collected and reserved for reuse next time.

[0102] After filtering, mix with 800 grams of zirconium beads with a diameter of 1 mm in a micro-stirring mill and grind for 2 hours at a speed of 80 r...

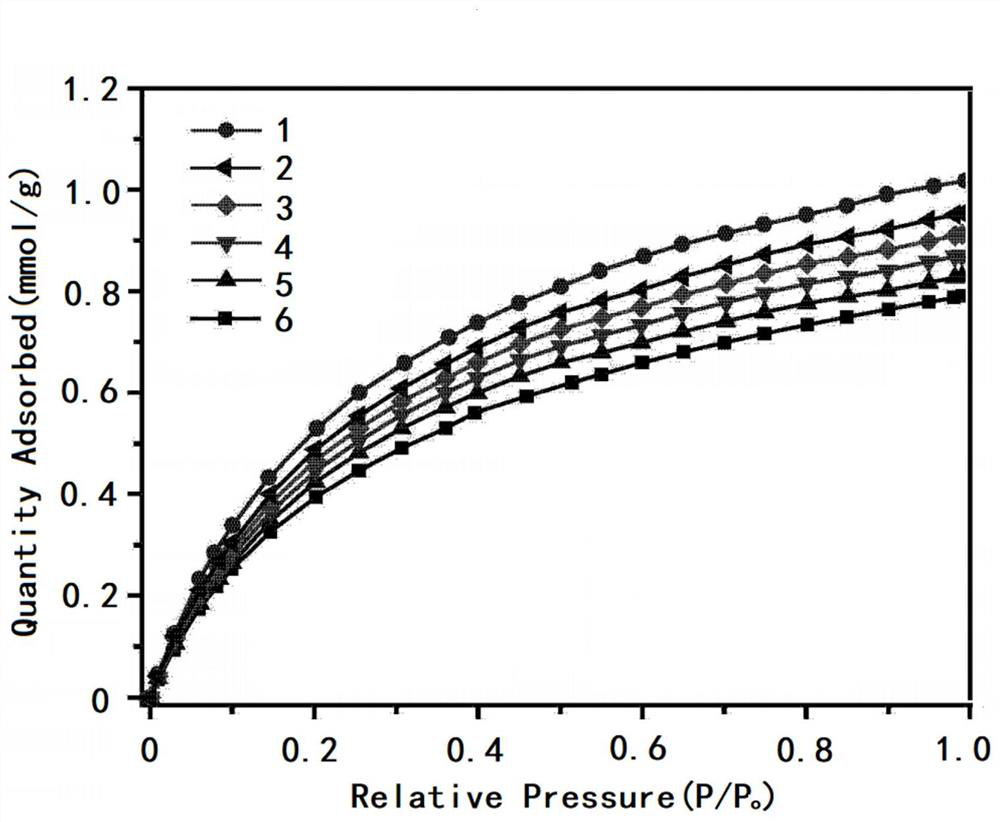

Embodiment 2

[0119] This example is used to illustrate the convenient and controllable increase of the rare earth content of the rare earth-containing Li-LSX zeolite prepared under the high exchange degree of lithium ions by adopting the method of the present invention.

[0120] Add 0.7 liters of water glass (same as above) and 1 liter of low-basic sodium metaaluminate (same as above) to 1.5 liters of deionized water and mix well, then add at room temperature, mix and stir and statically crystallize at 92°C for 8 hours.

[0121] After filtering, use the reclaimed filtrate that contains cerium nitrate earlier, exchange it at 80°C for 2 hours by the ratio of liquid / solid 20:1, dry and roast at 400°C for 2 hours, then use 4wt% cerium nitrate solution ( Same as above) exchanged at 80° C. for 2 hours, and recovered the filtrate exchanged with rare earth.

[0122] After filtering, mix and grind with 1.5 kg of zirconium beads with a diameter of 1 mm in a small stirring mill for 2 hours at a speed...

Embodiment 3

[0126] This example is used to illustrate the method of the present invention, under the condition of high exchange degree of lithium ions, it is convenient and controllable to prepare Li-LSX zeolite with higher rare earth content.

[0127] Add 1.5 liters of water glass (same as above) and 2 liters of low-alkalinity sodium metaaluminate (same as above) into 2.5 liters of deionized water and mix evenly. After mixing and stirring evenly, statically crystallize at 96° C. for 5 hours.

[0128] After filtration, exchange the filtrate with the recovered cerium ion at 90°C for 1 hour at a ratio of liquid / solid 10:1, and repeat the exchange once, dry and roast at 420°C for 1.5 hours, and then use 4wt% cerium nitrate solution Exchange under the same temperature conditions for 1 hour at the ratio of liquid / solid 5:1.

[0129] After filtering, mix and grind with 3 kg of zirconium beads with a diameter of 1 mm in a small stirring mill for 2 hours at a speed of 60 rpm. After sieving the zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com