Nano composite material as well as preparation method and application thereof

A nanocomposite material and inorganic nanomaterial technology, applied in the medical field, can solve the problems of decreased ROS generation efficiency, easy recombination of electrons and holes, wide band gap, etc., and achieve the effects of efficient ROS generation, enhanced effect, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

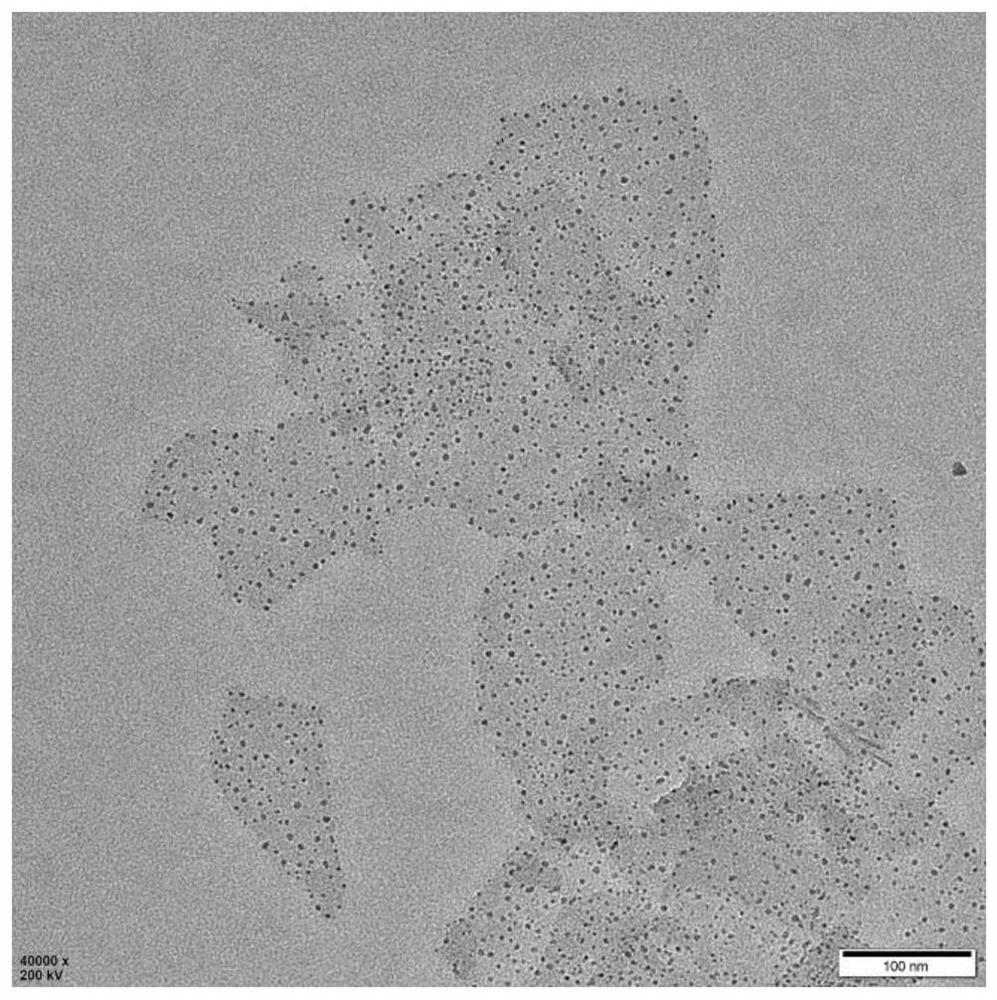

[0048] The present invention also provides a method for preparing the nanocomposite material described in the above technical solution, comprising the following steps:

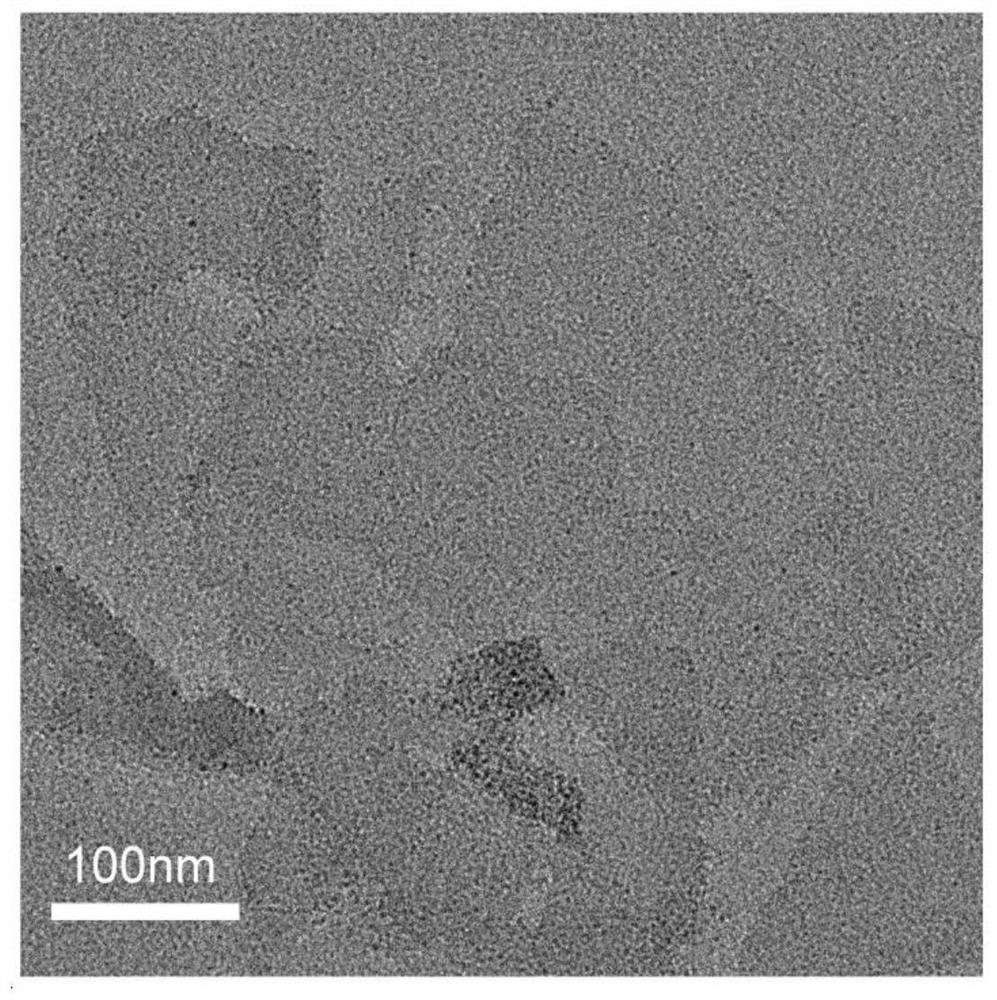

[0049] The two-dimensional structure Ti 3 C 2 Nanosheets, positively charged CuO 2 The nanodots are mixed with bovine serum albumin (BSA), and the solid and liquid are separated to obtain a nanocomposite material.

[0050] In the preparation method provided by the present invention, the two-dimensional structure Ti 3 C 2 Nanosheets are preferably prepared according to the following steps:

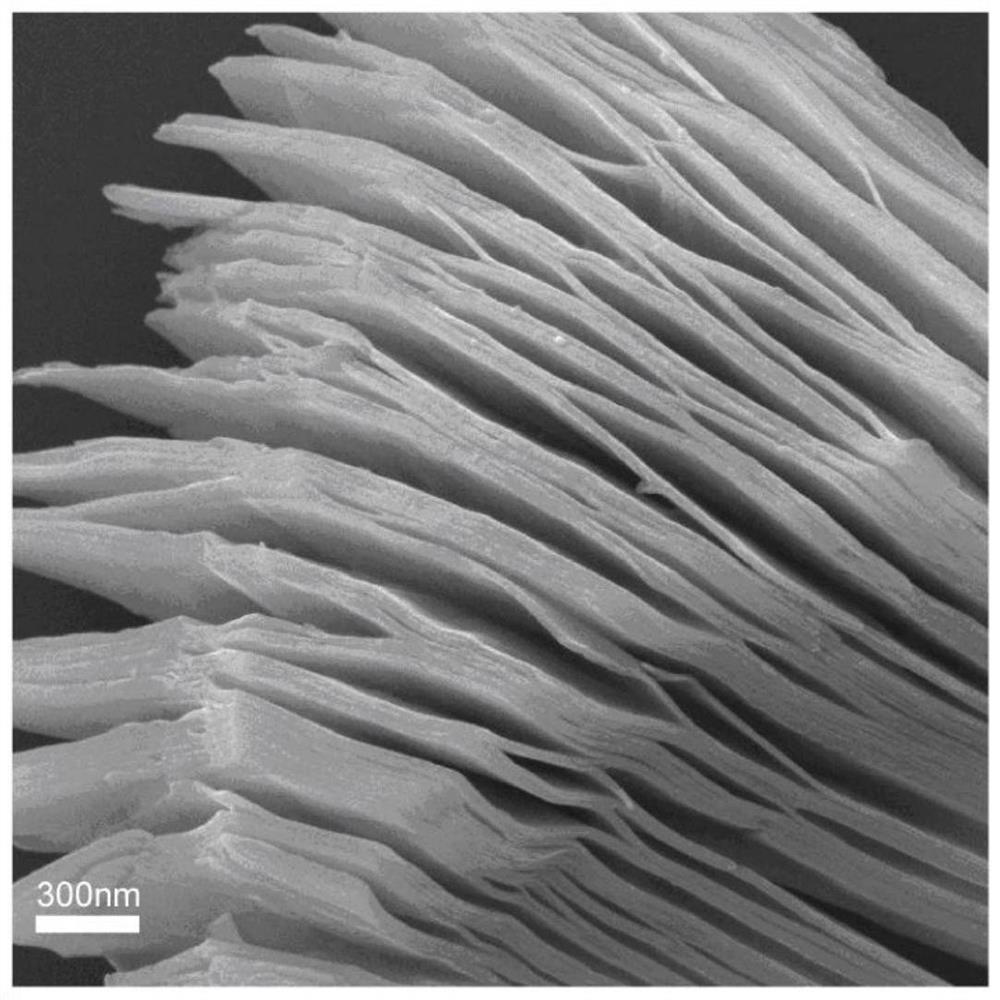

[0051] Ti 3 AlC 2 The powder is sequentially subjected to hydrofluoric acid etching treatment and tetrapropylammonium hydroxide intercalation treatment to obtain a two-dimensional structure Ti 3 C 2 nanosheets; where the etching treatment is aimed at removing Ti 3 AlC 2 In the Al layer, the purpose of the intercalation treatment is to transform the material into ultra-thin two-dimensional nanosheets.

[0052] In ...

Embodiment 1

[0076] 1) Ultra-thin two-dimensional structure Ti 3 C 2 Preparation of nanosheets:

[0077] Preparation of Ultrathin Two-Dimensional Structured Ti by Liquid Phase Exfoliation Method Using Hydrofluoric Acid (HF) Etching and Cationic Intercalation Agent (TPAOH) Intercalation 3 C 2 Nanosheets, the specific process is: mix titanium powder (Ti, 325 mesh), aluminum powder (Al, 325 mesh) and graphite powder (graphite, 300 mesh) at a molar ratio of 2:1:1, ball mill for 10 hours, and Cylindrical Ti under pressure 3 AlC 2 Biscuit: Under the protection of argon (Ar), the biscuit is heated to 1500°C in a high-temperature sintering furnace for sintering, and after two hours of heat preservation and sintering, the furnace is cooled to room temperature (25°C) to obtain a MAX phase ceramic block material ( Ti 3 AlC 2 ); pulverize Ti with a mortar and pestle 3 AlC 2 The ceramic block obtained a powder with a particle size of 300-500nm, 10g of the powder was magnetically stirred at 600...

Embodiment 2

[0089] Ti prepared in embodiment 1 3 C 2 / CuO 2 -BSA nanoparticles (Ti 3 C 2 / CuO 2 / BSA molar ratio is 1:2:2) biosafety evaluation:

[0090] 1) Culture U87 glioma cells and HUVEC human vein endothelial cells in vitro, and evaluate Ti 3 C 2 / CuO 2 -BSA nanoparticles are toxic to tumor cells, and the specific process includes:

[0091] Set up two 96-well culture plates, each plate is divided into 7 groups, and each group is set up with 5 multiple wells; add 100uL to each well of plate A at a density of 1×10 4 Glioma cells, add 100uL to each well of plate b with a density of 5×10 3 Human vein endothelial cells, cultured for 24 hours, after the cells adhered to the wall, added equal dilutions of different concentrations of Ti 3 C 2 / CuO 2 -BSA nanoparticles, continue to culture for 24 hours, then add CCK-8 to incubate for 1 hour, detect the cell viability in each well, and measure the absorbance at 450nm with a microplate reader.

[0092] Ti 3 C 2 / CuO 2 -BSA nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com