High-carboxyl-substituted hairy cellulose nanocrystal and preparation method thereof

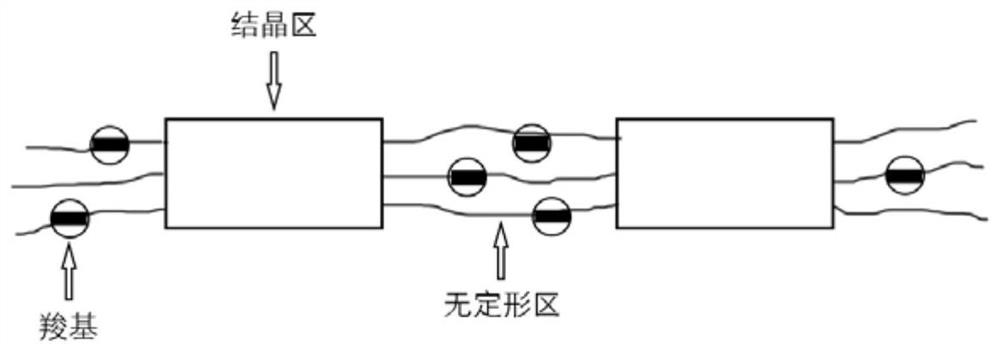

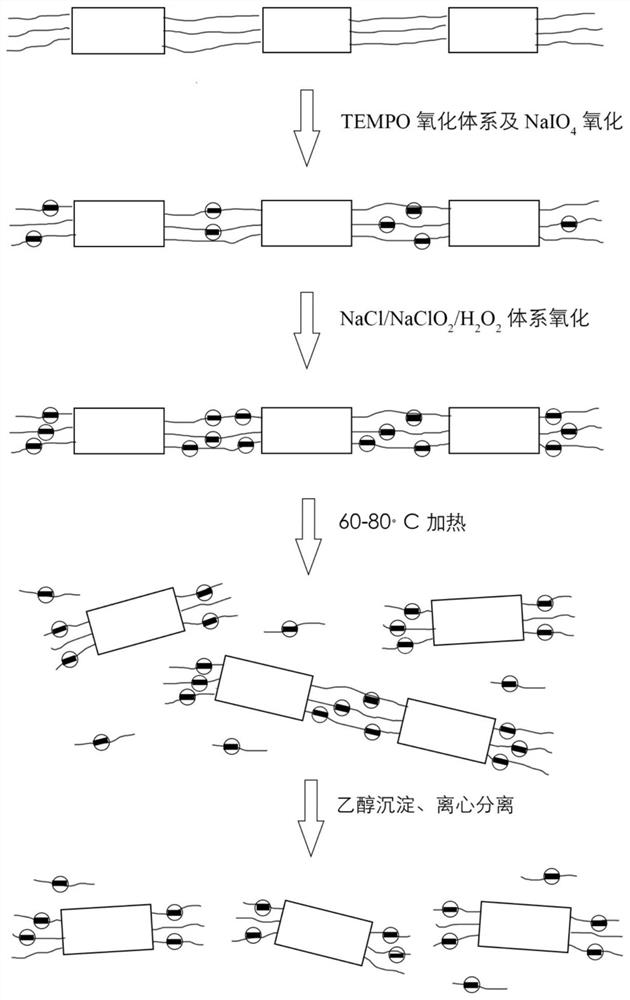

A technology of carboxylated cellulose and nanocrystals, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of affecting the stability of the product nanocellulose crystal, affecting the purity of the final product NCC, cellulose Problems such as the loss of amorphous areas, to achieve the effect of high amorphous cellulose content, increase product charge content, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

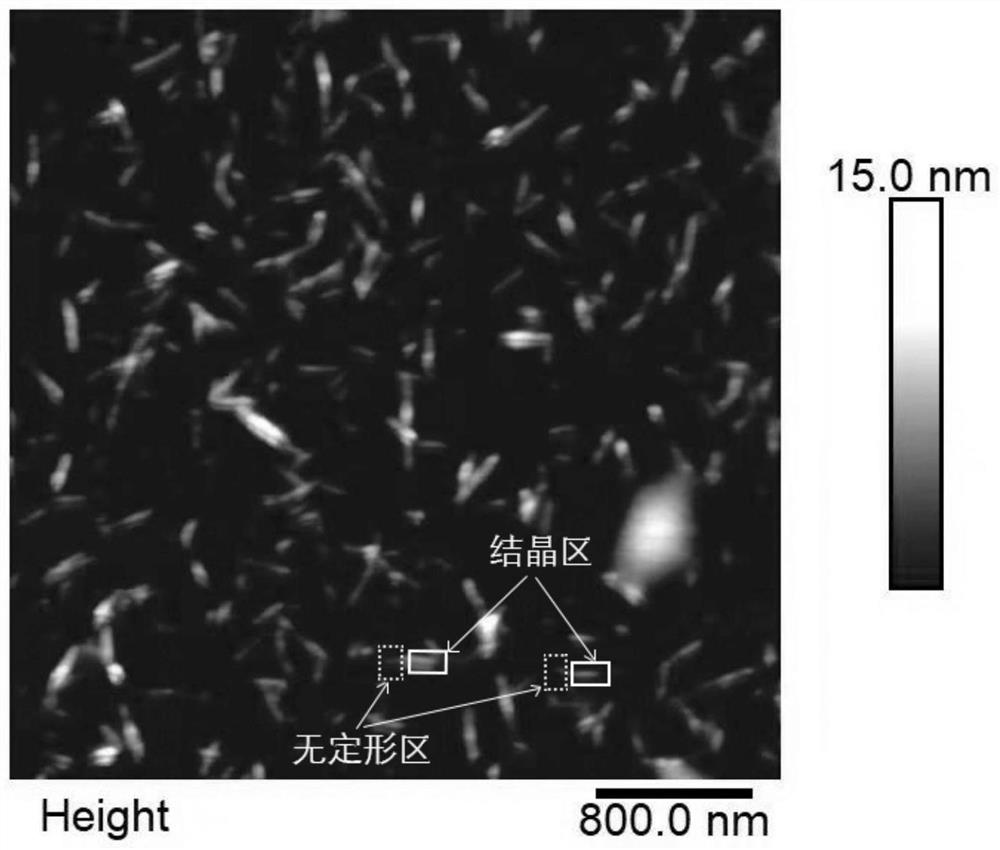

Image

Examples

Embodiment 1

[0049] Using sisal slag fiber as raw material, each gram of absolute dry fiber was dissolved in 100mL of phosphate buffer (0.05mol / L, pH=7) to form a slurry with a concentration of 1% (w / v), and added TEMPO0.016g, 10mmol NaClO 2 and 1mmol NaClO; at 60°C, 500rpm magnetic stirring for 6h after the reaction, the pH remained unchanged, and 100mL of absolute ethanol was added to terminate the reaction, and the obtained oxidized sample was repeatedly washed until the pH of the solution was neutral, and the precipitated slurry was collected by filtration. The oxidized cellulose was added into deionized water to form a 0.5% (w / v) suspension, treated with 800W ultrasonic for 30 minutes, then vacuum-filtered and washed until the pH value was neutral. Add 150mL of acetic acid-sodium acetate buffer solution with a pH of 4.5 to every gram of C6-carboxyl nanocellulose, add 3g of sodium periodate to every gram of C6-carboxyl nanocellulose, and avoid stirring at 30°C and 200rpm After 6 hours...

Embodiment 2

[0052] Using eucalyptus fiber as raw material, each gram of dry fiber was dissolved in 100mL of phosphate buffer (0.05mol / L, pH=7) to form a slurry with a concentration of 1% (w / v), and TEMPO was added to it 0.016g, 9mmol NaClO 2 and 2mmol NaClO; at 55°C, under 500rpm magnetic stirring for 6h, the pH remained unchanged, and 100mL of absolute ethanol was added to terminate the reaction, and the obtained oxidized sample was repeatedly washed until the pH of the solution was neutral, and the precipitated slurry was collected by filtration. The oxidized cellulose was added into deionized water to form a 0.8% (w / v) suspension, treated with 1000W ultrasonic for 30 minutes, then vacuum-filtered and washed until the pH value was neutral. Add 150mL of acetic acid-sodium acetate buffer solution with a pH of 4.5 to every gram of C6-carboxyl nanocellulose, add 3g of sodium periodate to every gram of C6-carboxyl nanocellulose, and avoid stirring at 30°C and 200rpm After 8 hours of photore...

Embodiment 3

[0055] Using bamboo fiber as raw material, each gram of dry fiber is dissolved in 100mL of phosphate buffer (0.05mol / L, pH=7) to form a slurry with a concentration of 1% (w / v), and TEMPO 0.018 g, 9 mmol NaClO 2and 3mmol NaClO; at 55°C, under 450rpm magnetic stirring for 7h, the pH remained unchanged, and 100mL of absolute ethanol was added to terminate the reaction, and the obtained oxidized sample was repeatedly washed until the pH of the solution was neutral, and the precipitated slurry was collected by filtration. The oxidized cellulose was added into deionized water to form a 0.6% (w / v) suspension, treated with 900W ultrasonic for 40 minutes, then vacuum-filtered and washed until the pH value was neutral. Add 200mL of acetic acid-sodium acetate buffer solution with a pH of 4.5 to every gram of C6-carboxyl nanocellulose, add 5g of sodium periodate to every gram of C6-carboxyl nanocellulose, and avoid stirring at 35°C and 198rpm. After 5 h of photoreaction, 5 mL of ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com