Catalyst for low-temperature efficient treatment of VOCs and preparation method of catalyst

A catalyst and high-efficiency technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that catalysts cannot convert VOCs at low temperature, and achieve low precious metal loading, good stability, and easy The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

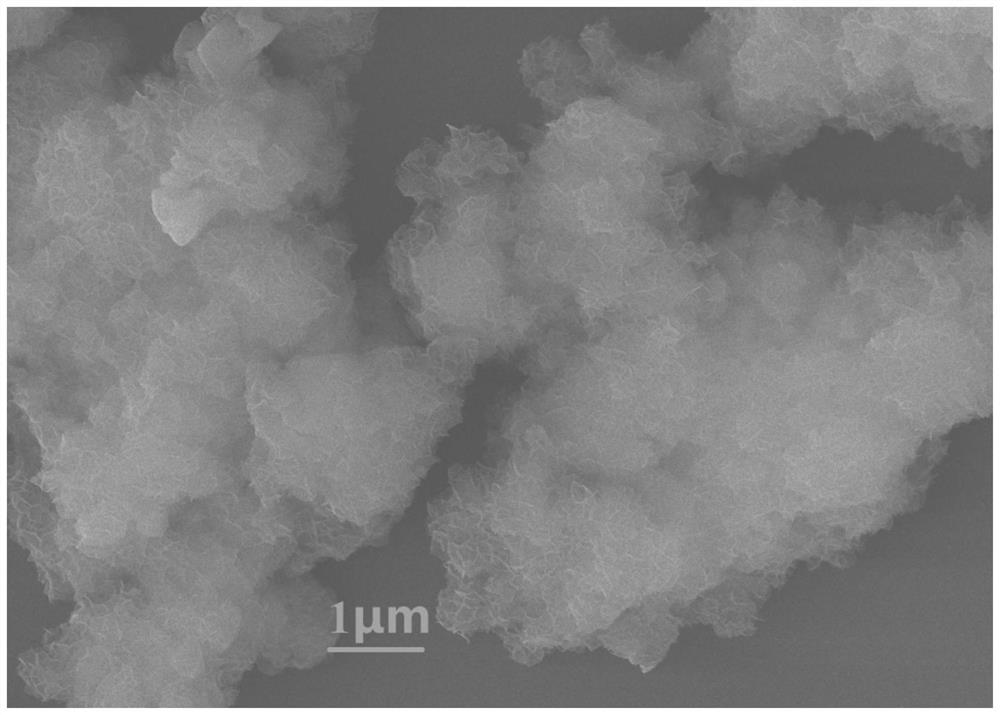

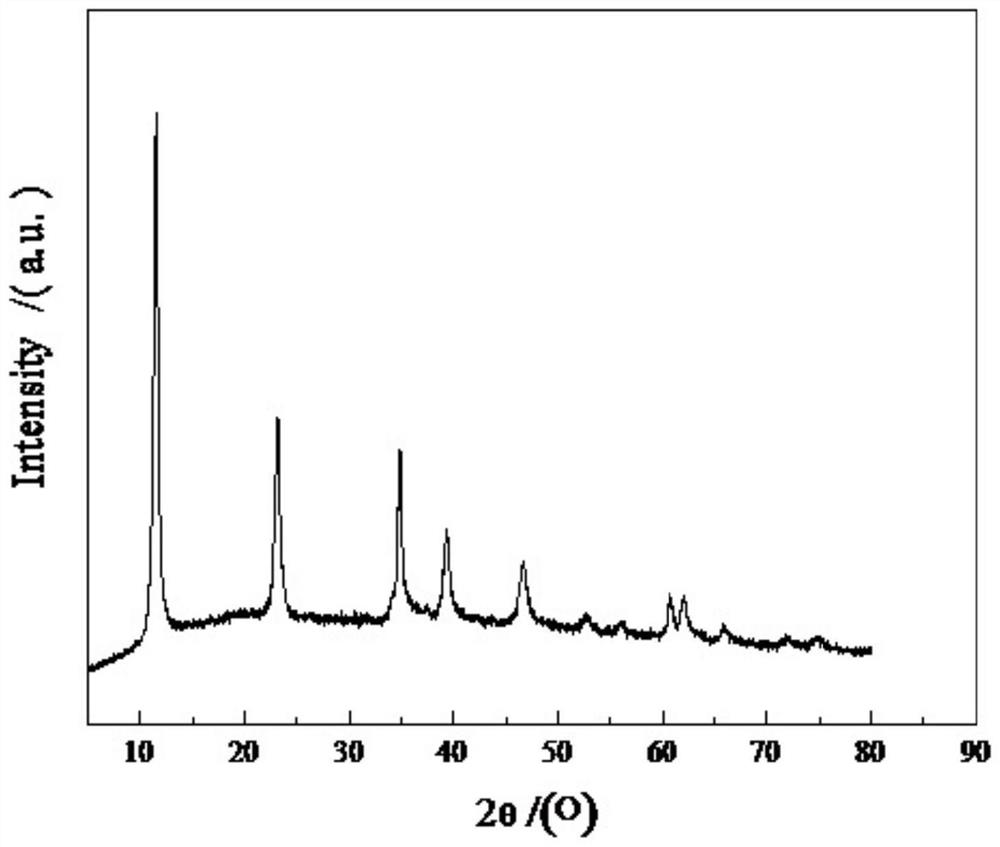

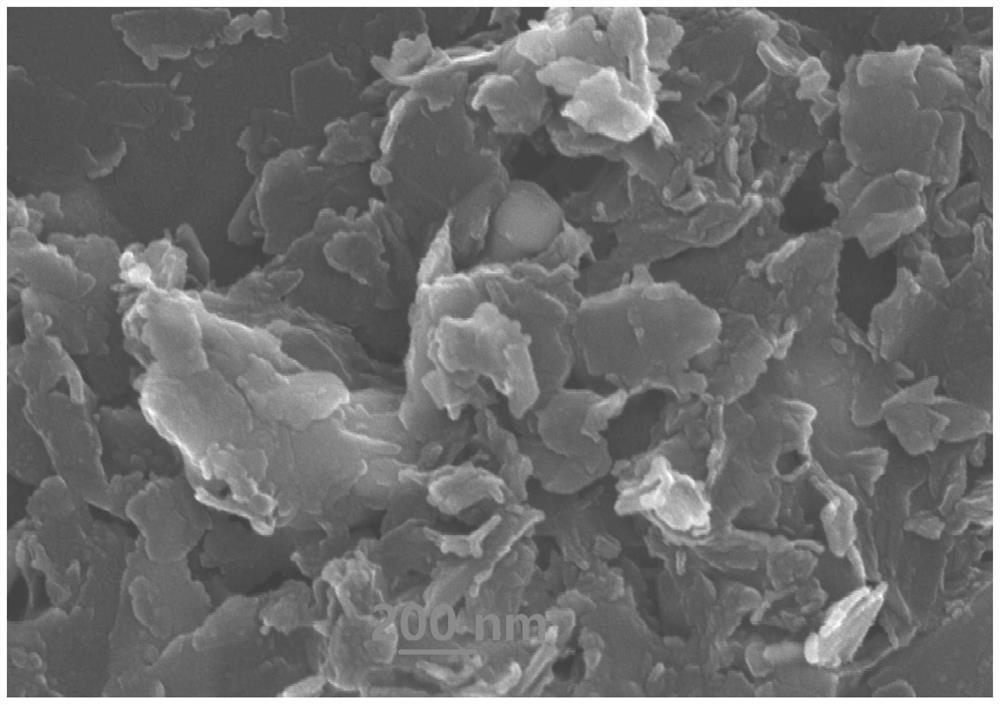

Image

Examples

Embodiment 1

[0037] A catalyst for low-temperature and high-efficiency treatment of VOCs, wherein the catalyst is loaded with 0.02% platinum, the molar ratio of Co:Al:Fe in the catalyst is 8:1:0.2, and the precipitant is ammonium bicarbonate. The specific preparation method is as follows:

[0038] (1) Dissolve 1.0 g of chloroplatinic acid hexahydrate with 2 ml of 1 mol / L hydrochloric acid to a volume of 50 ml; then take 130 μL of the solution and dissolve it in 15 ml of ethylene glycol, stir and dissolve to make liquid A;

[0039] (2) Weigh 2.91g of cobalt nitrate hexahydrate and 0.17g of aluminum trichloride, add 80ml of deionized water and stir for 30 minutes, add 0.07g of ferric chloride hexahydrate and continue stirring for 30 minutes until completely dissolved, and make B liquid;

[0040] (3) Transfer liquid B to a three-necked flask with reflux, slowly add 2.4 g of ammonium bicarbonate to liquid B under stirring, after dissolving, heat up to 65°C, and continue stirring for 4 hours; ...

Embodiment 2

[0044] A catalyst for low-temperature and high-efficiency treatment of VOCs, wherein the catalyst is loaded with 0.10% palladium, the molar ratio of Mn:Al:Mg:Ni in the catalyst is 1:1:1:2, and ammonia water is selected as the precipitating agent. The specific preparation method is as follows:

[0045] (1) Dissolve 1.0 g of chloropalladium acid hexahydrate with 1 mol / L hydrochloric acid to a volume of 50 ml; then take 178 μL of the solution and dissolve it in 15 ml of 1,3-butanediol, stir and dissolve to make liquid A;

[0046] (2) Take by weighing 0.62g manganese acetate tetrahydrate, aluminum trichloride of 0.33g, magnesium nitrate of 0.37g, nickel sulfate hexahydrate of 1.31g, add the deionized water of 80ml and stir until completely dissolving, make B liquid;

[0047] (3) Transfer liquid B to a three-necked flask with reflux, add 3ml of 25% ammonia water dropwise to liquid B under stirring, after dissolving, heat up to 90°C, and continue stirring for 4h;

[0048] (4) Contr...

Embodiment 3

[0051] A catalyst for low-temperature and high-efficiency treatment of VOCs, wherein the catalyst is loaded with 0.50% ruthenium, the molar ratio of Ni:Mg:Zn:Al in the catalyst is 8:1:0.5:1, and ammonia water is selected as the precipitating agent. The specific preparation method is as follows:

[0052] (1) Dissolve 1.0 g of ruthenium trichloride with 1 mol / L hydrochloric acid to a volume of 50 ml; then take 187 μL of the solution and dissolve it in 15 ml of 1,3-propanediol, stir and dissolve to make liquid A;

[0053] (2) Take by weighing 2.91g nickel nitrate hexahydrate, the anhydrous magnesium nitrate of 0.19g, the aluminum chloride of the zinc nitrate hexahydrate of 0.18g and 0.17g, the deionized water of 80ml is stirred until dissolving completely, makes B liquid;

[0054] (3) Transfer liquid B to a three-necked flask with reflux, slowly add 1.0 g of ammonium bicarbonate and 1.56 g of urea to liquid B under stirring, and heat up to 120° C. after dissolving;

[0055] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com