Method for separating and recycling waste lithium battery pole piece material

A waste lithium battery, separation and recycling technology, applied in battery recycling, lithium storage battery, waste collector recycling and other directions, can solve the problems of aluminum foil crushing, difficult recycling, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Raw material preparation: Soak waste batteries in 5% sodium chloride solution and discharge to 0V.

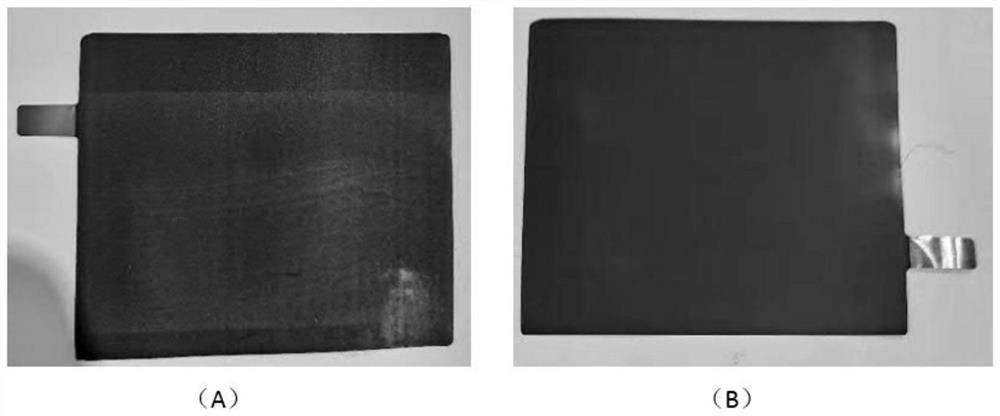

[0063] (2) Under a negative pressure environment, disassemble the waste lithium battery provided by (1) after discharge, remove the battery casing, take out the battery cell, and remove the diaphragm wrapping the positive and negative electrodes, respectively, as follows: figure 2 The shown positive electrode current collector is a positive electrode sheet of aluminum and the negative electrode current collector is a negative electrode sheet of copper, wherein figure 2 (A) is the positive electrode sheet, (B) is the negative electrode sheet.

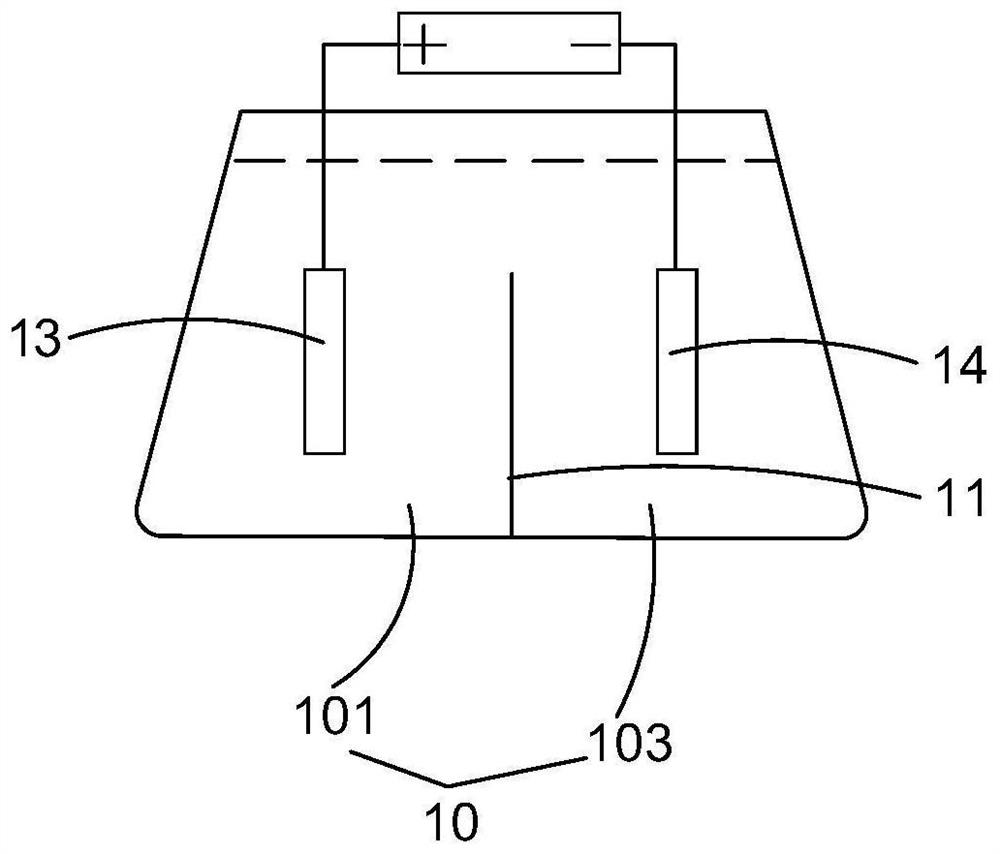

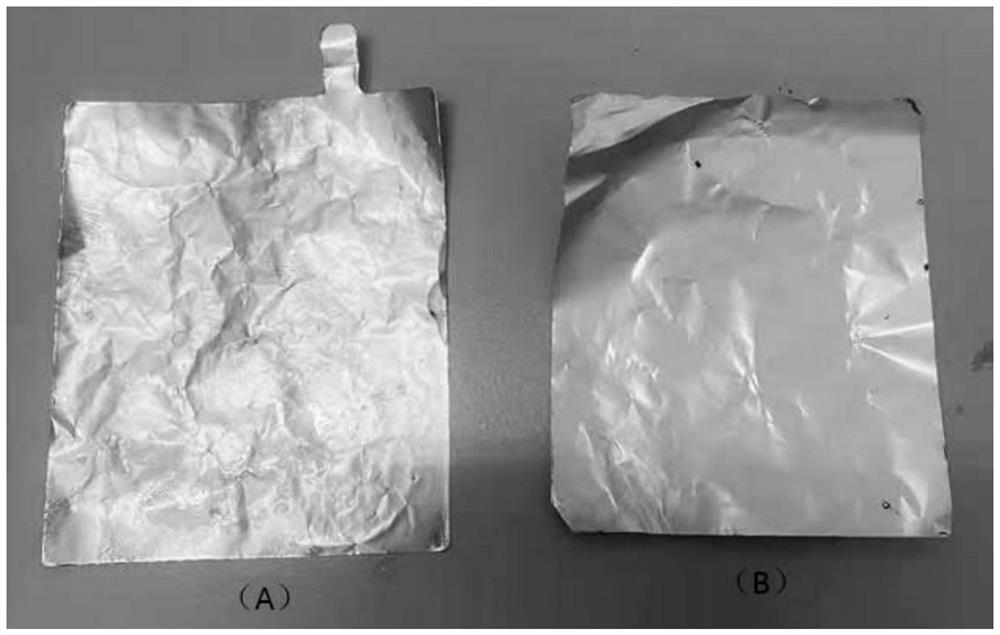

[0064] (3) Electrolyzer preparation: Put the positive electrode sheet and the negative electrode sheet into the positive electrode coating layer collection tank and the negative electrode coating layer collection tank respectively, then add an alkaline aqueous solution with a mixed alkali content of 1moL / L into the electrolyt...

Embodiment 2

[0073] (1) Raw material preparation: Soak waste batteries in 10% by mass sodium chloride solution and discharge to 0V.

[0074] (2) Under a negative pressure environment, disassemble the used lithium battery provided in (1) after discharge, remove the battery case, take out the battery cell, remove the diaphragm wrapping the positive and negative electrodes, and obtain the positive electrode with the tab broken respectively The positive electrode sheet whose current collector is aluminum and the negative electrode sheet whose tabs are broken are copper negative electrode sheets.

[0075] (3) electrolyzer preparation: the electrolyzer is provided with the first nickel sheet that is positioned at the positive electrode coating layer collection tank, and is positioned at the second nickel sheet of the negative electrode coating layer collection tank, the positive electrode sheet and the negative electrode sheet that (2) obtains are respectively Put into the positive electrode coa...

Embodiment 3

[0082] It differs from Embodiment 1 only in steps 3)-(5).

[0083] (3) Electrolyzer preparation: put the positive electrode sheet and the negative electrode sheet into the positive electrode coating layer collection tank and the negative electrode coating layer collection tank respectively, then add 1moL / L sodium hydroxide aqueous solution into the electrolytic cell and fill up the electrolytic cell, At this time, the aqueous sodium hydroxide solution has not passed through the separator.

[0084] (4) Large current pulse: Obtain a power supply with the same function as the battery charge and discharge test cabinet. The positive line of the power supply output by the power supply clamps the tab of the positive plate in (3), and the negative line of the power supply output by the power supply clamps ( 3) In the tab of the negative electrode sheet, the anode and the cathode are energized to perform high-current pulse charge-discharge cycle treatment for 5 minutes, then stop, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com