Nanofiber membrane material for cleansing cotton and preparation method of nanofiber membrane material

A nanofiber membrane and makeup-removing cotton technology, which is applied to the nanofiber membrane material for makeup-removing cotton and the field of preparation thereof, can solve the problems of complicated operation, high cost, and thick cotton sheet layer, and achieves good air permeability, low cost, and easy use. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

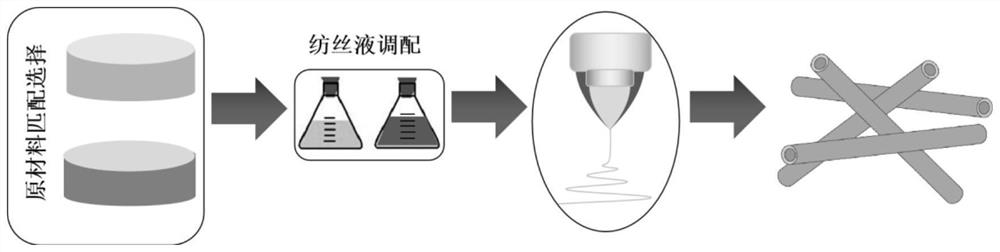

[0025] figure 1 Exemplarily described a preparation method of nanofiber membrane material for makeup remover cotton, the steps are as follows:

[0026] Step 1, adding PVP and CA powder as precursors to a mixed solvent containing Ac, DMAc, and EtOH, and stirring on a magnetic stirrer to obtain a clear polymer solution;

[0027] Step 2, adding PVP powder to EtOH mixed with cleansing oil, stirring on a magnetic stirrer to obtain a translucent polymer solution;

[0028] In step three, a coaxial electrospinning process is used, and the polymer solution in steps one and two is used as the electrospinning solution for the sheath layer and the core layer to prepare a nanofiber membrane material.

Embodiment 1

[0030] Sheath solution configuration: Use a pipette to pipette 40mlAc, 10ml DMAc, and 10ml EtOH into a 100ml screw-necked conical flask to obtain a mixed solvent of Ac, DMAc, and EtOH. Use an electronic analytical balance to weigh PVP and CA powder respectively and add Add a magnetic rotor to the screw-necked Erlenmeyer flask containing the mixed solvent of Ac, DMAc, and EtOH, and tighten the bottle cap, where PVP:CA=1:4 (w / w), and place the Erlenmeyer flask at room temperature Stirring on a magnetic stirrer for 24h, a colorless and transparent solution was obtained.

[0031] Core liquid configuration: use a pipette to pipette 100ml of absolute ethanol and 5ml of cleansing oil into a screw-top conical flask, weigh PVP powder with an electronic analytical balance and add it to a screw-top conical flask containing ethanol and cleansing oil In , add a magnetic rotor and tighten the bottle cap, wherein the PVP is 13% (w / v), place the Erlenmeyer flask on a magnetic stirrer at room ...

Embodiment 2

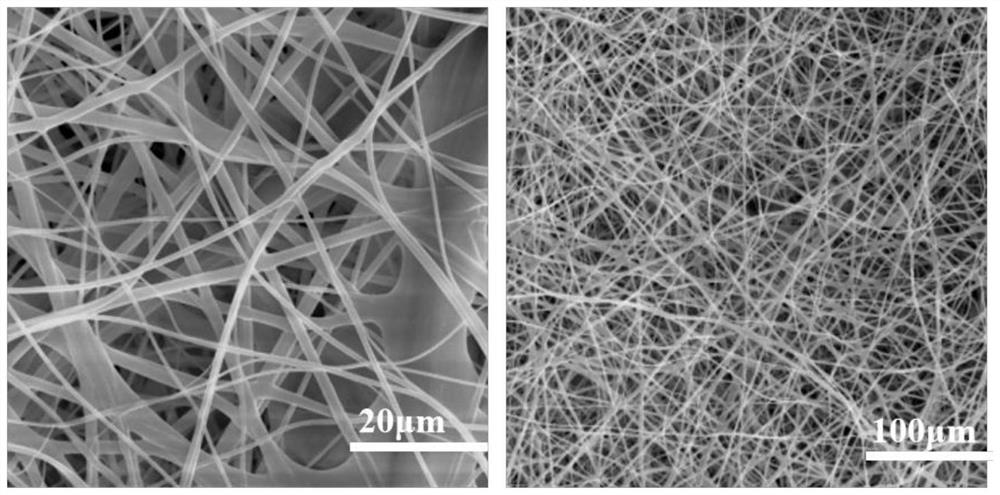

[0035] Collect the fiber film prepared in Example 1 with aluminum foil, seal the sample in a drying dish with a plastic bag, and let the solvent evaporate completely, then place the sample dry. Cut the prepared fiber membrane with aluminum foil, fix it on the scanning electron microscope (SEM) sample stage with conductive glue, and spray gold on the surface of the sample in a nitrogen atmosphere by sputtering coating method to make the sample conductive. Then, the microscopic morphology of the samples was characterized by scanning electron microscopy, such as image 3 As shown, it can be seen that the fibers in the nanofibrous membrane have no beaded or spindle structure, and have a good linear morphology.

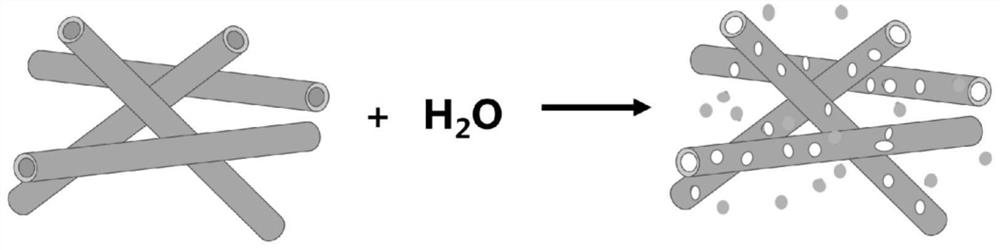

[0036] In summary, the present invention adopts the coaxial electrospinning process, and the ethanol / acetone / N,N dimethylacetamide solution of cellulose acetate mixed with a small amount of polyvinylpyrrolidone is used as the sheath layer, and the polyvinylpyrrolidone and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com