Preparation method of multi-layer heat insulation material

A technology of multi-layer thermal insulation material and composite material, which is applied in the field of preparation of multi-layer thermal insulation material, can solve the problems of lack of research on composite structure design and integrated molding process of thermal insulation layer, inability to control the dispersion and distribution state of ablation-resistant fillers, etc. , to achieve good thermal insulation effect, efficient synergistic utilization, and excellent ablation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

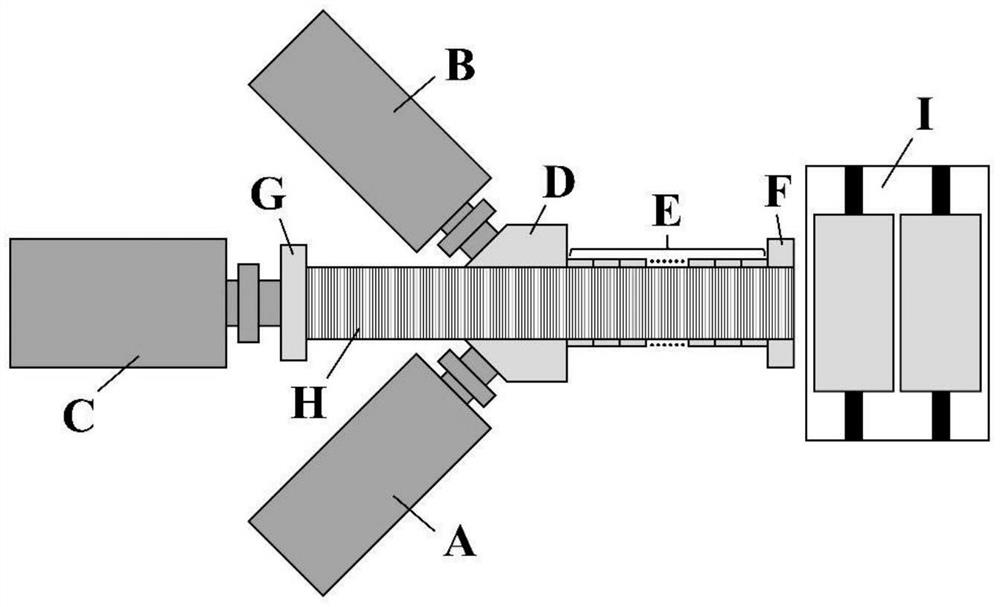

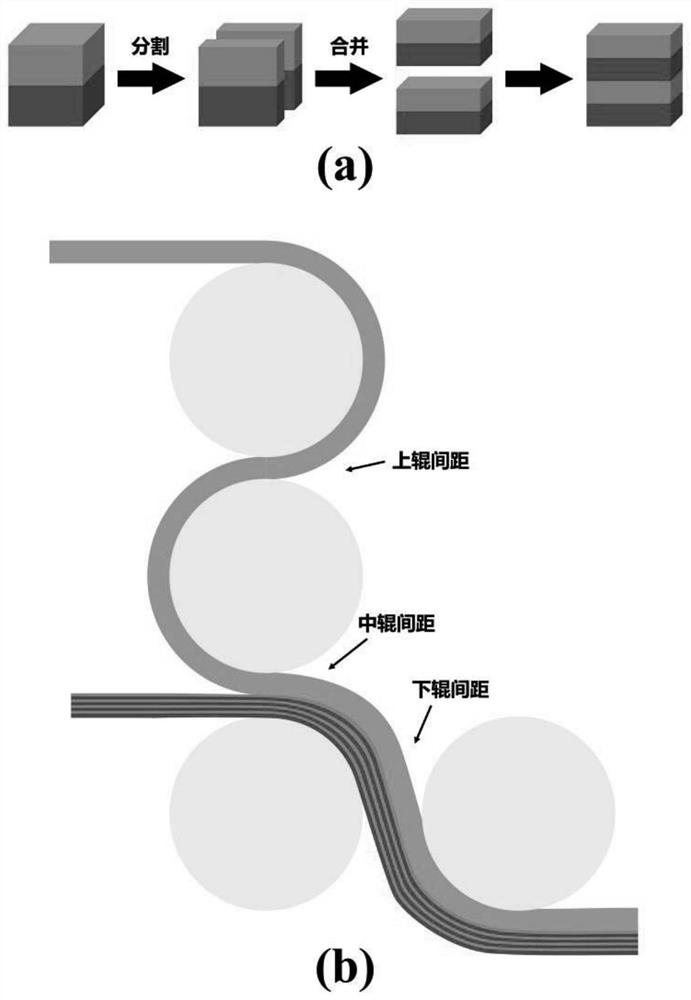

[0058] Embodiment 1, the preparation of multi-layer insulation material of the present invention

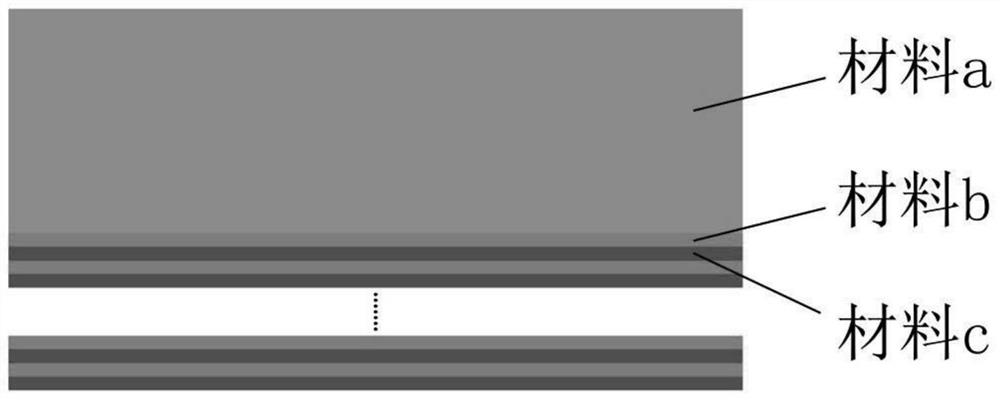

[0059] (EPDM rubber-based 9-layer material, total thickness 5mm, width 400mm, surface layer (material a) thickness 1.5mm (accounting for 30% of the total thickness ratio) alternate layers (material b and c) thickness 3.5mm, layer thickness ratio 1:1)

[0060] According to the following components and parts: (1) Material a: Ablation-resistant surface layer: EPDM rubber 100kg, aramid fiber 5kg, carbon fiber 5kg, carbon black 20kg, carbon nanotube 5kg, boronated phenolic resin 20kg, oxidation 5kg of zinc, 1.5kg of sulfur, 1kg of accelerator M1kg, 1kg of accelerator ZDC and 4kg of paraffin oil; (2) Material b: ablation-resistant inner layer: EPDM rubber 100kg, aramid fiber 3kg, carbon fiber 3kg, silicon dioxide 20kg, boronized phenolic resin 10kg, zinc oxide 5kg, sulfur 1.5kg, accelerator M1kg, accelerator ZDC 1kg and paraffin oil 4kg; (3) Material c: light insulation layer: EPDM ru...

Embodiment 2

[0065] Embodiment 2, the preparation of multi-layer thermal insulation material of the present invention

[0066] (EPDM rubber-based 9-layer material, total thickness 10mm, width 400mm, surface layer (material a) thickness 4mm (accounting for 40% of the total thickness) alternating layers (material b and c) thickness 6mm, layer thickness ratio 1: 1)

[0067] According to the following components and parts: (1) Material a: Ablation-resistant surface layer: EPDM rubber 100kg, aramid fiber 5kg, carbon fiber 5kg, carbon black 20kg, carbon nanotube 5kg, boronated phenolic resin 20kg, oxidation Zinc 5kg, peroxide curing agent 2kg and paraffin oil 4kg; (2) Material b: ablation-resistant inner layer: EPDM rubber 100kg, aramid fiber 3kg, carbon fiber 3kg, silicon dioxide 20kg, boronized phenolic resin 10kg, zinc oxide 5kg, peroxide vulcanizing agent 2kg and paraffin oil 4kg; (3) Material c: light insulation layer: EPDM rubber 100kg, carbon black 20kg, boronated phenolic resin 10kg, ho...

Embodiment 3

[0072] Embodiment 3, the preparation of multi-layer thermal insulation material of the present invention

[0073] (EPDM-based 9-layer material, total thickness 10mm, width 400mm, surface layer (material a) thickness 4.8mm (48% of the total thickness ratio) alternate layers (material b and c) thickness 5.2mm, layer thickness ratio 1:1)

[0074] According to the following components and parts: (1) Material a: Ablation-resistant surface layer: EPDM rubber 100kg, aramid fiber 5kg, carbon fiber 5kg, carbon black 20kg, carbon nanotube 5kg, boronated phenolic resin 20kg, oxidation Zinc 5kg, peroxide curing agent 2kg and paraffin oil 4kg; (2) Material b: ablation-resistant inner layer: EPDM rubber 100kg, aramid fiber 3kg, carbon fiber 3kg, silicon dioxide 20kg, boronized phenolic resin 10kg, zinc oxide 5kg, peroxide vulcanizing agent 2kg and paraffin oil 4kg; (3) Material c: light insulation layer: EPDM rubber 100kg, carbon black 20kg, boronated phenolic resin 10kg, hollow glass micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com