Deep sea environment corrosion-resistant coating and preparation method thereof

A technology for corrosion-resistant coatings and deep-sea environments, applied in coatings, metal material coating processes, ion implantation plating, etc., can solve problems such as nodule defects, penetrating defects, pinhole defects, etc., and achieve porosity reduction , reduce the density, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

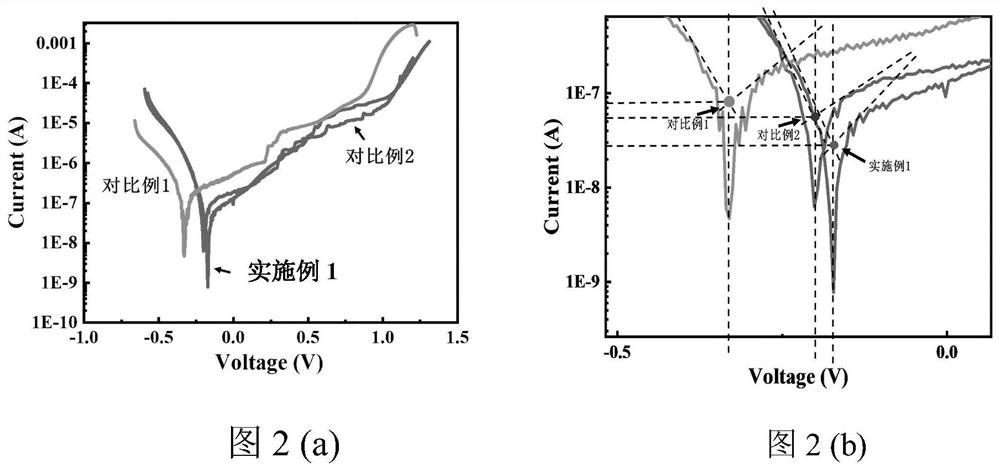

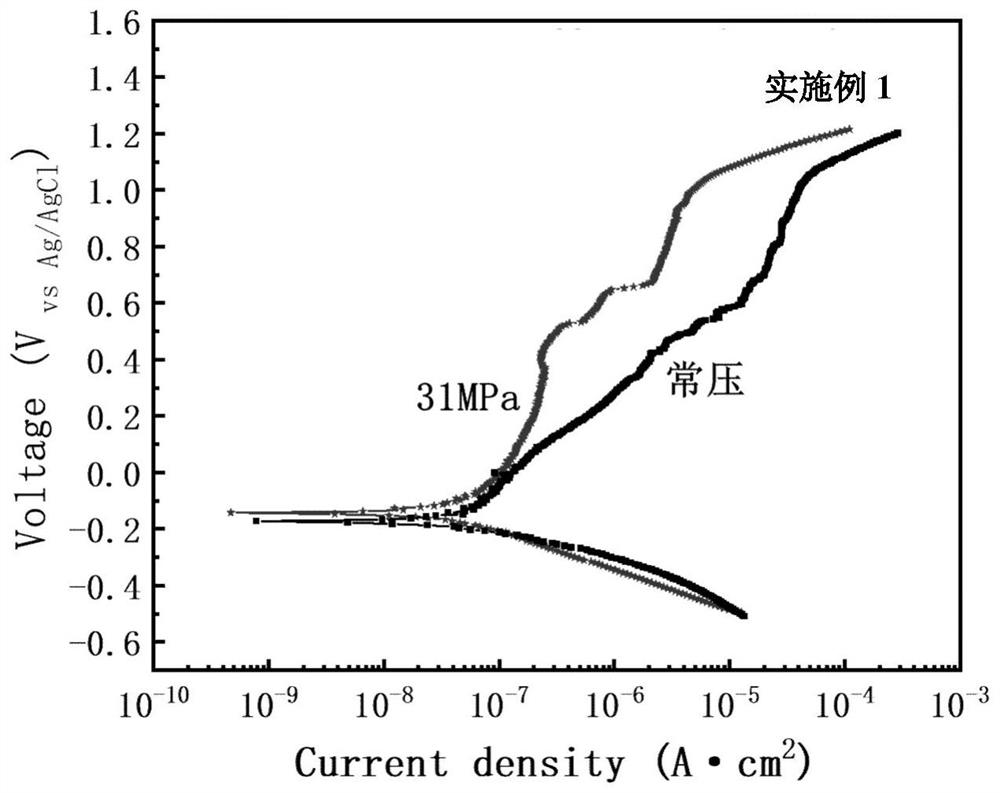

Embodiment 1

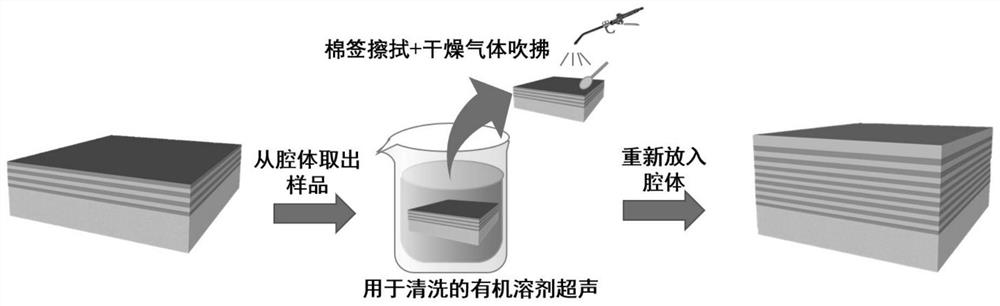

[0045] In this embodiment, the preparation method of the coating is as follows figure 1 shown, the specific steps are as follows:

[0046] 1. The base is made of 17-4PH stainless steel, and the stainless steel is ultrasonically cleaned with acetone and ethanol. After drying, it is placed in a vacuum chamber, fixed on the workpiece bracket, and evacuated to 3.0×10 -5 Below Torr, then under the conditions of helium flow rate of 35sccm and bias voltage of -150V, the ion source was turned on, the current was adjusted to 0.15A, and the substrate surface was etched with helium plasma for 30min;

[0047] 2. Pour helium gas into the cavity (the amount of helium gas is 55sccm), adopt DC magnetron sputtering technology, maintain the pressure of the cavity at 2.0mTorr, turn on the DC power supply connected to the chromium sputtering target, and set the power supply The frequency is 350Hz, the current is 2.5A, the substrate bias is -150V, the deposition temperature is 150°C, the chromium...

Embodiment 2

[0084] In the present embodiment, the preparation method of coating is as follows:

[0085] 1. The base is made of 2507 duplex stainless steel. The stainless steel is ultrasonically cleaned with acetone and ethanol. After drying, it is placed in a vacuum chamber, fixed on the workpiece bracket, and evacuated to below 2.0×10-5 Torr. Under the condition that the negative bias voltage is 100V, the ion source is turned on, the current is 0.1A, and the substrate surface is etched by krypton plasma for 40min;

[0086] 2. Pour krypton gas into the cavity (the inflow amount of krypton gas is 50sccm), adopt DC magnetron sputtering technology, maintain the pressure of the cavity at 1.9mTorr, turn on the DC power supply connected to the chromium sputtering target, and set the power supply The frequency is 350Hz, the current is 2.5A, the substrate bias voltage is -100V, the deposition temperature is 120℃, the chromium transition layer is deposited, and nitrogen gas (the amount of nitrogen...

Embodiment 3

[0098] In the present embodiment, the preparation method of coating is as follows:

[0099] 1. The base is made of 431 stainless steel. The stainless steel is ultrasonically cleaned with acetone and ethanol. After drying, it is placed in a vacuum chamber, fixed on the workpiece bracket, and evacuated to 4.0×10 -5 Torr or less, then under the conditions of argon flow rate of 40sccm and bias voltage of -200V, turn on the ion source, adjust the current to 0.2A, and use argon plasma to etch the surface of the substrate for 40min;

[0100] 2. Pour argon gas into the cavity (the amount of argon gas is 60sccm), adopt DC magnetron sputtering technology, maintain the pressure of the cavity at 2.1mTorr, turn on the DC power supply connected to the chromium sputtering target, and set the power supply The frequency is 350Hz, the current is 3A, the substrate bias is -200V, the deposition temperature is 180℃, the chromium transition layer is deposited, and nitrogen gas (the amount of nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com