Bifunctional catalyst as well as preparation method, application and application method thereof

A dual-function catalyst, catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of high separation energy consumption, low production efficiency, and high purity requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of the catalyst, comprising the following steps:

[0048] (1) mixing lanthanum nitrate, alkaline earth metal precursor, iron nitrate, transition metal precursor, complexing agent, water and glycol to obtain a sol;

[0049] (2) drying and roasting the sol in sequence to obtain a composite material;

[0050](3) The composite material, the alkali metal compound and water are mixed and then dried and calcined in sequence to obtain the bifunctional catalyst.

[0051] In the present invention, the complexing agent in the step (1) is preferably citric acid, and the dihydric alcohol is preferably ethylene glycol.

[0052] In the present invention, the mass ratio of the lanthanum nitrate to the complexing agent is preferably 7-8:20-24, more preferably 7.2-7.8:21-23, more preferably 7.4-7.6:21.5-22.5.

[0053] In the present invention, the dosage ratio of the lanthanum nitrate to water is preferably 7-8g: 180-220mL, more ...

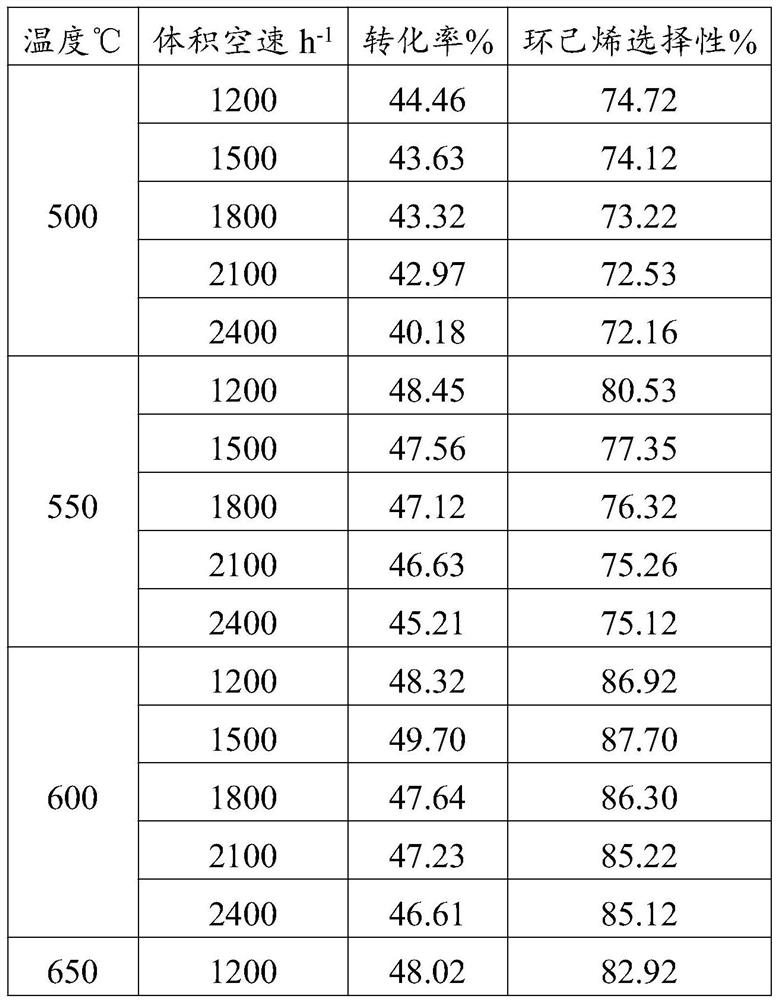

Embodiment 1

[0083] Dissolve 7.32g of lanthanum nitrate hexahydrate, 0.89g of strontium nitrate, 7.69g of ferric nitrate nonahydrate and 0.79g of molybdenum nitrate pentahydrate in 200mL of water, stir at 500rpm for 60min to obtain a metal nitrate mixed solution; mix the metal nitrates The solution was mixed with 22.21g of citric acid, and stirred at 1000rpm for 35min; after the stirring was completed, it was mixed with 9.84g of ethylene glycol, and the temperature was raised to 80°C at a heating rate of 5°C / min, and stirred while the temperature was rising. The rotational speed was 1500 rpm, and the stirring was continued for 8 hours after reaching 80° C. to obtain a sol.

[0084] Dry the sol at 80°C and -0.1MPa for 11 hours, raise the temperature of the solid material obtained by drying to 450°C at a heating rate of 10°C / min, and roast for 1 hour after reaching 450°C to complete the first roasting; after the first roasting , continue to heat up to 950°C at a heating rate of 10°C / min, and...

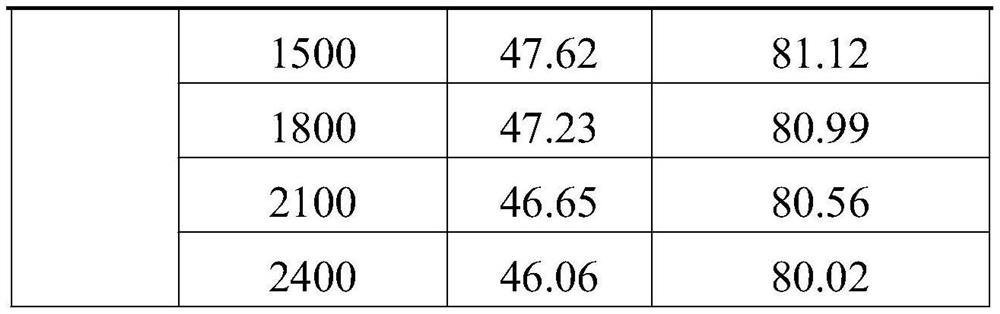

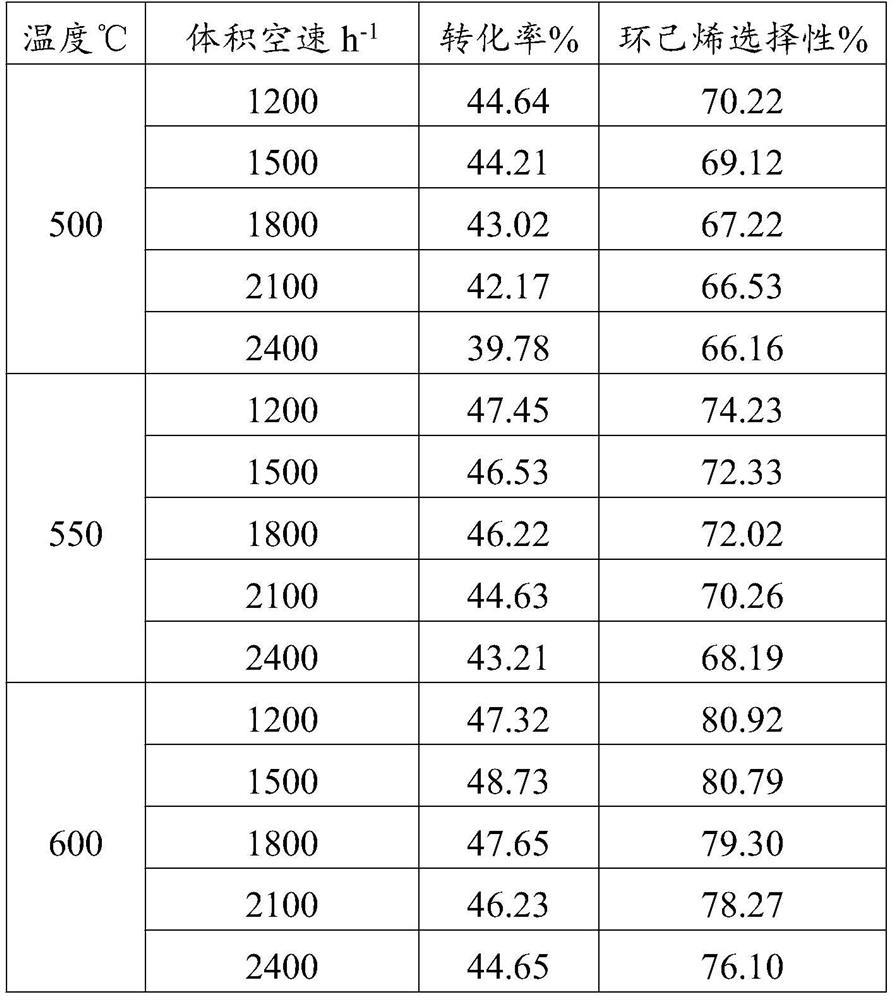

Embodiment 2

[0094] Get 7.90g lanthanum nitrate hexahydrate, 1.16g magnesium nitrate hexahydrate, 8.29g ferric nitrate nonahydrate and 0.27g ammonium metavanadate and dissolve them in 220mL of water, stir at 600rpm for 50min to obtain a metal nitrate mixed solution; Mix the salt mixed solution with 23.95g of citric acid, stir at 1000rpm for 40min; after the stirring is completed, mix with 10.61g of ethylene glycol, raise the temperature to 78°C at a heating rate of 4°C / min, and stir while raising the temperature. The stirring speed was 1450 rpm, and the stirring was continued for 7.5 hours after reaching 78° C. to obtain a sol.

[0095] Dry the sol at 78°C and -0.12MPa for 12 hours, raise the temperature of the solid material obtained by drying to 450°C at a heating rate of 8°C / min, and roast for 1 hour after reaching 450°C to complete the first roasting; after the first roasting , continue to heat up to 950°C at a heating rate of 8°C / min, and after reaching 950°C, roast for 8 hours to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com