Ultrahigh-temperature-resistant, heat-insulating and antioxidant ceramic coating

A ceramic coating, anti-oxidation technology, applied in the field of ceramic coating, can solve the problems of ultra-high temperature resistance, thermal insulation and thermal insulation performance to be further improved, etc., achieve excellent thermal shock cycle life, improve high temperature resistance and thermal insulation performance, The effect of high temperature resistance and fracture toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

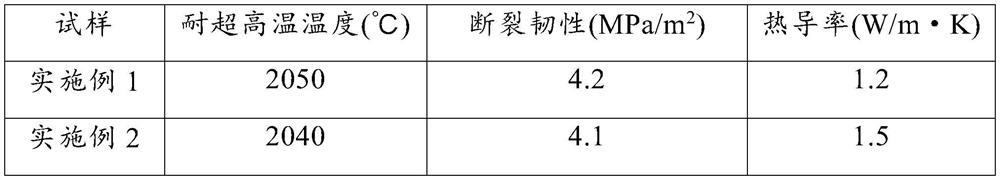

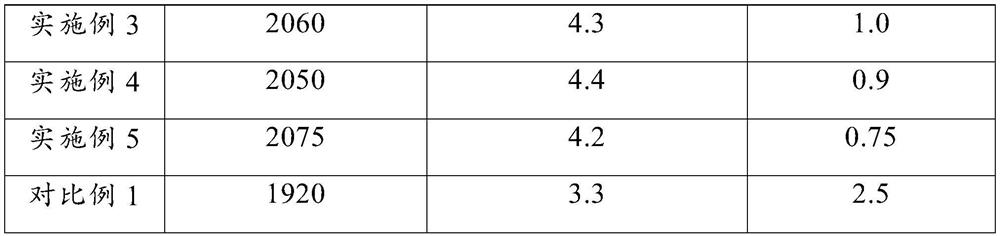

Examples

preparation example Construction

[0038] The preparation method of silica coated silicon carbide composite microspheres includes:

[0039] S1. Preparation of olerate cellulose in butyrates in silicon carbide nanoparticles;

[0040] S2. The product obtained by step S1 is dispersed in an aqueous solution, warmed to 40-60 ° C, then orthosoricate and ethyl acetate, and adjust the pH to 10.5-11.5 reaction for 5-10 h, then centrifugation;

[0041] S3. Disperse the product obtained by step S2 in ethanol solution of ammonium nitrate, 80 ° C refluxed for 6 h, remove ethyl acetate, to obtain a mesoporous silica layer;

[0042] S4. The product obtained by step S3 is dispersed in acetone solvent, heat reflux for 6 h, removes buterate butyrate cellulose, to obtain a hollow structure layer, and finally obtains silica coated silicon carbide composite microspheres having a cavity structure.

[0043] Preparation method for ultra-high temperature insulation antioxidant ceramic coating is: 30-50 parts of tantalum carbide, 20-35 copi...

Embodiment 1

[0046] A high temperature insulation antioxidant ceramic coating, a preparation method is: 38 parts of tantalum carbide according to weight, 23 copies of carbonide, 16 carbide, and 15 silica coated silicon carbide composite microspheres. 6 parts of zirconium dioxide and 2 boron nitride, mixed ball milling to obtain a mixed powder; mixed with anhydrous ethanol in mass than 1.5: 1, then applied to stainless steel metal surface, baked at 200 ° C for 1 h It is obtained to obtain a high temperature insulation antioxidant ceramic coating.

[0047] The preparation method of silica coated silicon carbide composite microspheres is roughly: dispersion of silicon carbide nanoparticles in a mixed solution of water and ethanol, warmed to 60 ° C, then orthosilicate, adjusting pH to 10.5 -11.5 Reaction 8 h, centrifugation was separated and dried to give silica coated silicon carbide composite microspheres.

Embodiment 2

[0049] A resistance to ultra-high temperature insulating antioxidant ceramic coating, which is compared to Example 1, and the raw material components include: 40 parts of carbon tantalum, 24 parts of carbonide, 18 parts of titanium carbide, and dioxide. Silicon-coated silicon carbide composite microspheres, 6 parts of zirconia and 2 boron nitride. Others are the same as that of Example 1, and details are not described herein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com