Monatomic copper/boron double-site multifunctional catalyst as well as preparation method and application thereof

A dual-site, multi-functional technology, applied in physical/chemical process catalysts, chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, etc., can solve the problem that the preparation method of copper-based single-atom catalyst cannot be large Production, limited development of copper-based double-site catalysts, poor controllability of electrode area, etc., to achieve the effects of easy scale-up experiments, low cost, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of single-atom copper / boron dual-site multifunctional catalyst, comprising the following steps:

[0049] A. Precursor preparation: add 0.1 g of copper chloride dihydrate, 2 g of melamine, 2 g of silicon dioxide, 0.4 g of potassium borate and 2 g of chitosan into a beaker containing 80 ml of deionized water, and heat the above mixture After stirring, 0.5 g of glacial acetic acid was added dropwise, and finally kept at 80 °C for continuous evaporation. After half of the water evaporated, it was cooled to room temperature and then placed in the cold well of a freeze dryer for 5 hours at -35 °C, and then vacuum freeze-dried. 12 hours, the precursor powder is prepared;

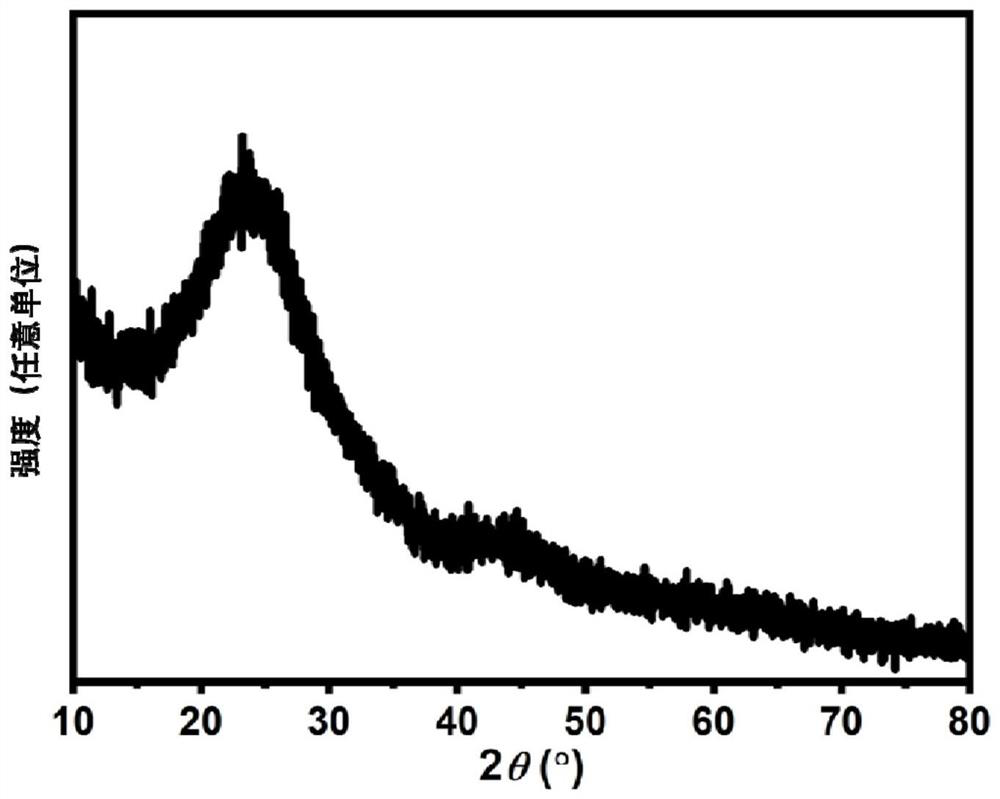

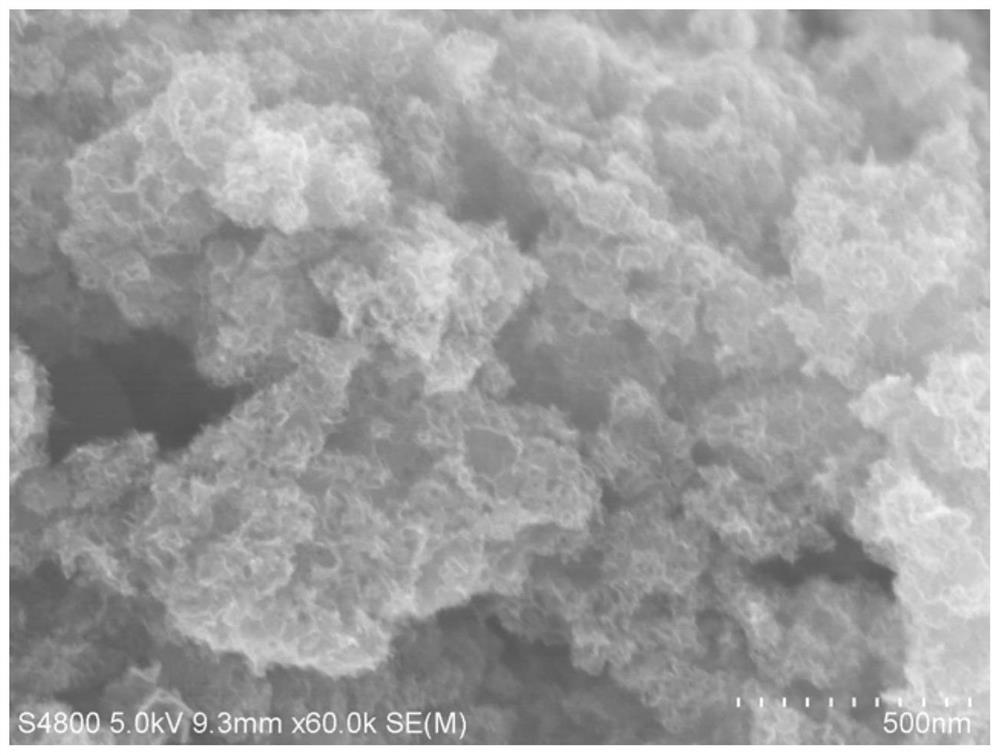

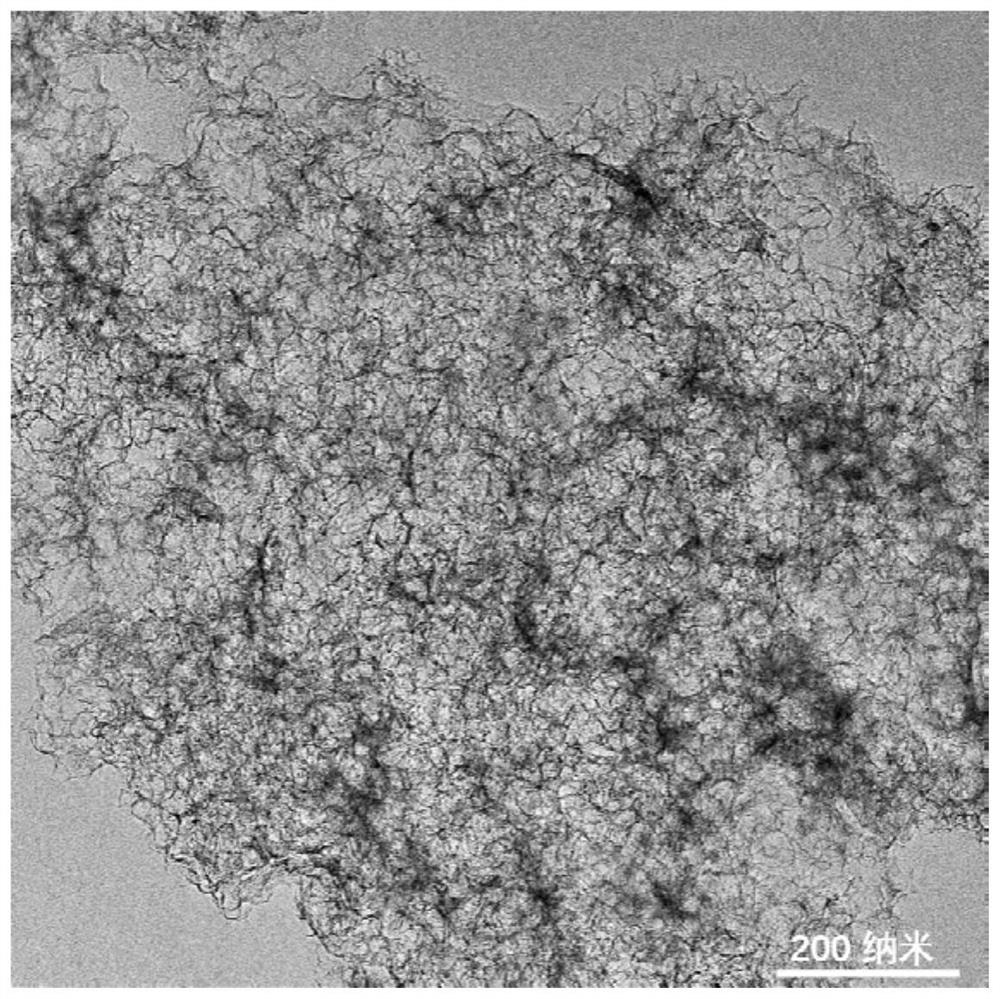

[0050] B. Pyrolysis: take 3 grams of the precursor powder prepared in step A, put it into a corundum porcelain boat with a lid, put it into a tube furnace, and heat it up to 550°C at 2°C / min in a nitrogen atmosphere, and keep the temperature for 3 hours. ; Then carry out secondary pyrol...

Embodiment 2

[0060] A preparation method of single-atom copper / boron dual-site multifunctional catalyst, comprising the following steps:

[0061] A. Precursor preparation: Add 0.15 g of copper sulfate pentahydrate, 0.5 g of melamine, 1.5 g of dicyanamide, 3 g of silicon dioxide, 0.4 g of potassium borate, and 2 g of chitosan into a beaker containing 80 ml of deionized water , after heating and stirring the above mixture, add 0.8 g of formic acid dropwise, and finally keep it at 80 °C and continue to evaporate. After half of the water has evaporated, cool it to room temperature and put it in the cold well of a freeze dryer and freeze it at -55 °C for 2 hours, then Carry out vacuum freeze-drying for 10 hours to obtain the precursor powder;

[0062] B. Pyrolysis: take 2 grams of the precursor powder prepared in step A, put it into a corundum porcelain boat with a cover, put it into a tube furnace, heat it up to 550°C at 2°C / min in a nitrogen atmosphere, and keep the temperature for 4 hours. ...

Embodiment 3

[0066] A preparation method of single-atom copper / boron dual-site multifunctional catalyst, comprising the following steps:

[0067] A. Precursor preparation: add 0.12 g of copper acetate monohydrate, 2 g of urea, 2 g of silicon dioxide, 0.25 g of ammonium borate, and 2 g of chitosan into a beaker containing 80 ml of deionized water, and the above mixture is heated and stirred After that, 0.6 g of lactic acid was added dropwise, and finally kept at 80 °C for continuous evaporation. After half of the water evaporated, it was cooled to room temperature and then placed in the cold well of a freeze dryer for 3 hours at -50 °C, and then vacuum freeze-dried for 12 hours. , that is, the precursor powder is obtained;

[0068] B. Pyrolysis: take 3 grams of the precursor powder prepared in step A, put it into a corundum porcelain boat with a lid, put it into a tube furnace, and heat it up to 550°C at 2°C / min in an argon atmosphere, and keep the temperature for 2 Hour; then carry out se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com