Synthesis method of high-content sodium calcium edetate

A technology of calcium sodium edetate and synthetic liquid, applied in the field of medicine and chemical industry, can solve the problems of uneven water content of particles, decreased main content of finished products, poor stability, etc., and achieve the effects of high product quality, uniform quality and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

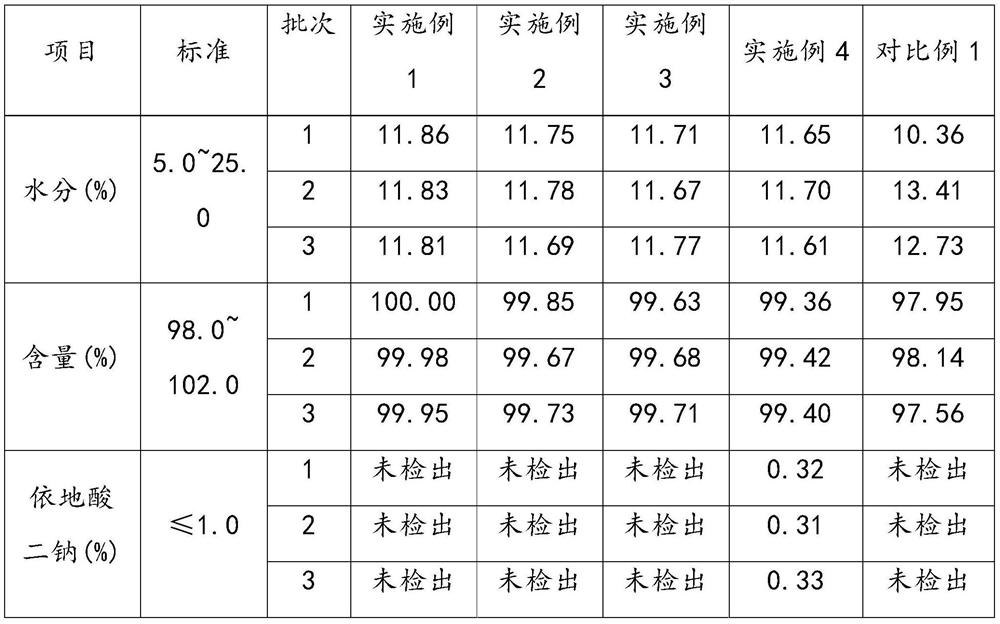

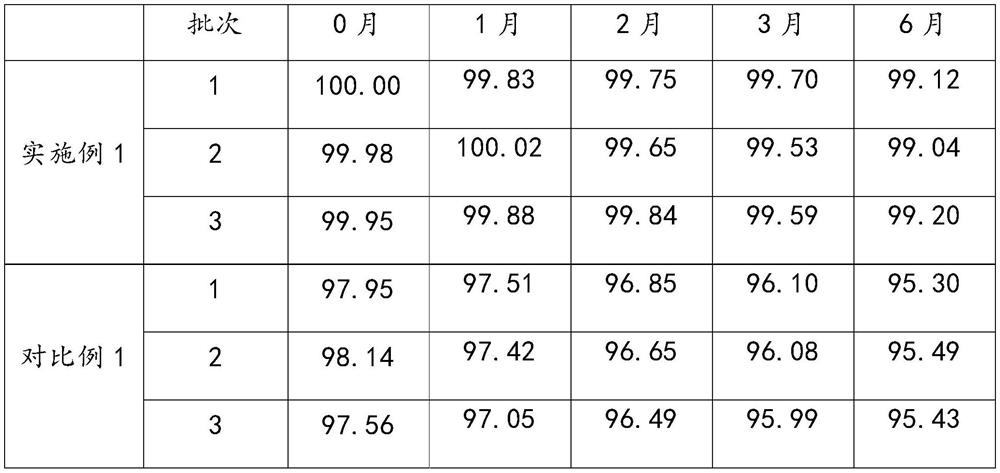

Examples

Embodiment 1

[0034] Dissolve 2kg of sodium hydroxide in 35kg of deionized water under stirring to obtain a sodium hydroxide solution with a concentration of 5.4wt%, and place it in a water bath at 60°C to keep it warm; slowly add ethylenediaminetetraacetic acid to it and keep stirring, ethylenediaminetetra The amount of acetic acid added was 7.3kg, the pH was adjusted to 4.5, and 2L of synthetic solution was taken out for later use. Calcium hydroxide was added to the above solution, the pH was adjusted to 11, and the reaction was continued for 30 minutes, then left to stand and filtered. Adjust the pH of the final synthesis solution to 7.1 with the spare synthesis solution taken out, and stir again for 30 minutes. Concentrate the synthetic liquid to 26°Bé (100°C), then add 30L of absolute ethanol, stir and stand for crystallization. The precipitated crystals were dispersed and suspended in dioxane / water (volume ratio 6:1) mixed solvent, and stirred at room temperature for 24 h. Filter, d...

Embodiment 2

[0036] Dissolve 2kg of sodium hydroxide in 35kg of deionized water under stirring to obtain a sodium hydroxide solution with a concentration of 5.4wt%, and place it in a water bath at 60°C to keep it warm; slowly add ethylenediaminetetraacetic acid to it and keep stirring, ethylenediaminetetra The amount of acetic acid added was 7.4kg, the pH was adjusted to 4.3, and 1.9L of synthetic solution was taken out for later use. Calcium hydroxide was added to the above solution, the pH was adjusted to 11, and the reaction was continued for 30 minutes, then left to stand and filtered. Adjust the pH of the final synthesis solution to 7.1 with the spare synthesis solution taken out, and stir again for 30 minutes. Concentrate the synthetic liquid to 26°Bé (100°C), then add 30L of absolute ethanol, stir and stand for crystallization. The precipitated crystals were dispersed and suspended in dioxane / water (volume ratio 6:1) mixed solvent, and stirred at room temperature for 24 h. Filter,...

Embodiment 3

[0038] Dissolve 2kg of sodium hydroxide in 35kg of deionized water under stirring to obtain a sodium hydroxide solution with a concentration of 5.4wt%, and place it in a water bath at 60°C to keep it warm; slowly add ethylenediaminetetraacetic acid to it and keep stirring, ethylenediaminetetra The amount of acetic acid added was 7.3kg, the pH was adjusted to 4.5, and 2L of synthetic solution was taken out for later use. Calcium oxide was added to the above solution, the pH was adjusted to 11, and the reaction was continued for 30 minutes, then left to stand and filtered. Adjust the pH of the final synthesis solution to 7.1 with the spare synthesis solution taken out, and stir again for 30 minutes. Concentrate the synthetic liquid to 26°Bé (100°C), then add 30L of absolute ethanol, stir and stand for crystallization. The precipitated crystals were dispersed and suspended in dioxane / water (volume ratio 6:1) mixed solvent, and stirred at room temperature for 24 h. Filter, dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com