Organic silicon modified polyurethane acrylate ultraviolet light and moisture dual-curing conformal coating and preparation method thereof

A polyurethane acrylate, acrylate technology, applied in polyurea/polyurethane coatings, fire retardant coatings, coatings, etc., to achieve excellent high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

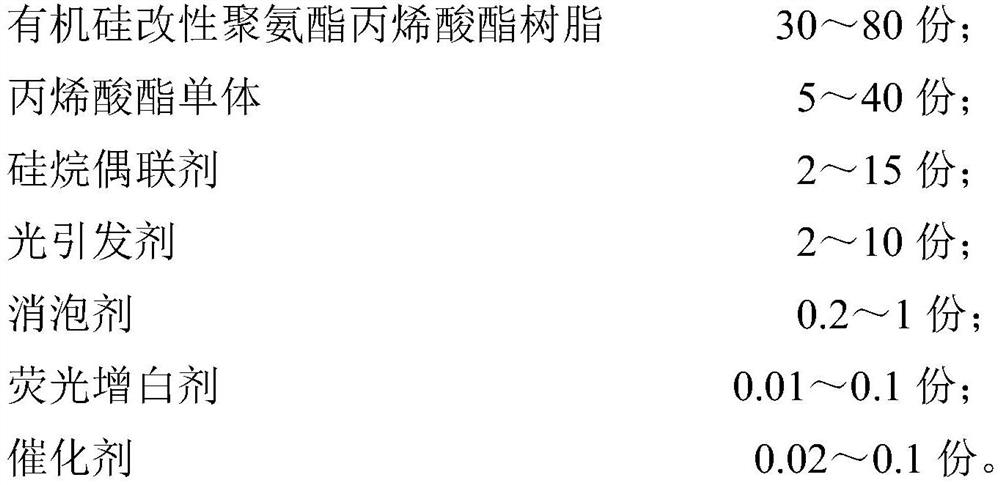

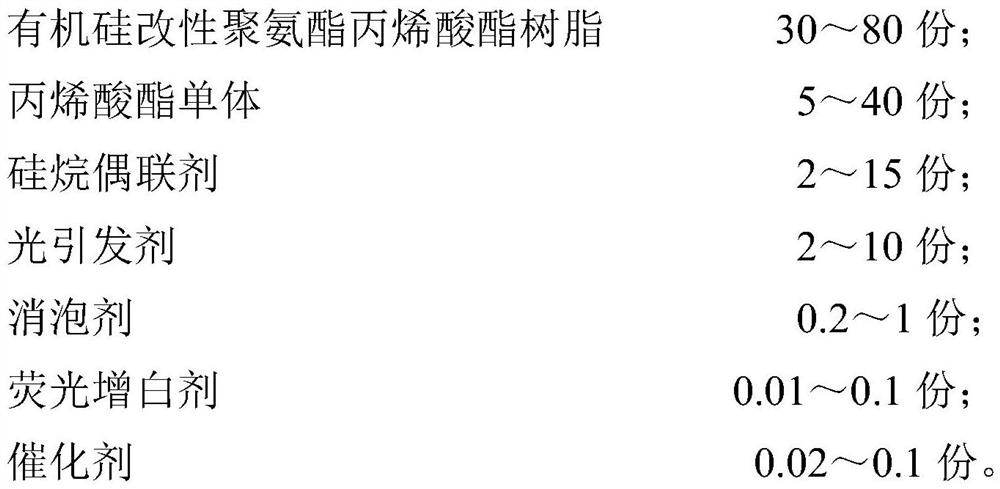

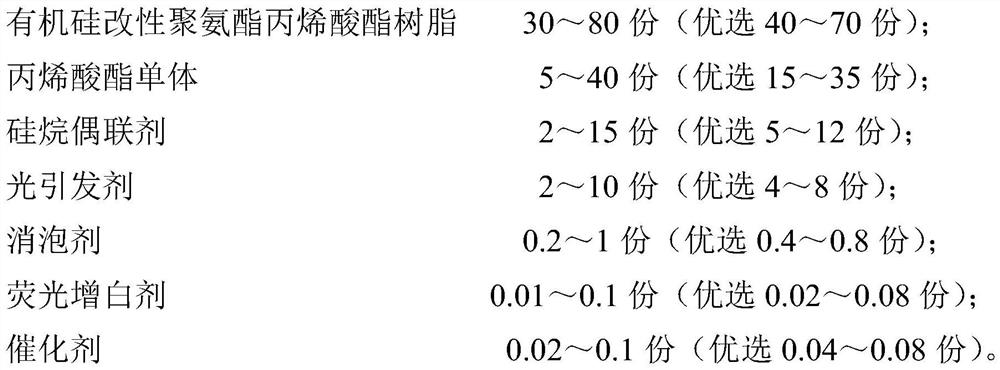

Method used

Image

Examples

Embodiment 1

[0030] In this example, 168.19g of hexamethylene diisocyanate, 120g of polyethylene glycol, 180g of hydroxy polydimethylsiloxane and 200g of toluene were added to a three-necked flask, and 0.05g of organotin catalyst was added. ℃ for 2 hours to prepare a prepolymer; then add 48 g of hydroxyethyl acrylate, react at 65 ℃ for 5 hours, and finally distill the toluene to prepare a silicone-modified urethane acrylate resin. Through testing and calculation, the molar ratio of isocyanate, carbon-carbon double bond and silicon-oxygen bond in the modified resin is 18:8:1.

[0031] The formula preparation process of the three anti-paint is: in parts by weight, 0.02 parts of optical brightener (OB), 0.82 parts of defoamer (BYK UV 3505 acrylate-modified polysiloxane), 5 parts of photoinitiator (1-hydroxycyclohexyl phenyl ketone), 10 parts of acrylate monomer (isobornyl acrylate) and 5.6 parts of silane coupling agent (acryloxypropyltrimethoxysilane) were added to the stirrer in sequence, ...

Embodiment 2

[0033] In this example, 168.19g of hexamethylene diisocyanate, 136g of polyethylene glycol, 180g of hydroxy polydimethylsiloxane and 200g of toluene were added to a three-necked flask, and 0.05g of organotin catalyst was added. ℃ for 2 hours to prepare a prepolymer; then add 54 g of hydroxypropyl acrylate, react at 65 ℃ for 5 hours, and finally distill off the toluene to prepare a silicone-modified urethane acrylate resin. Through testing and calculation, the molar ratio of isocyanate, carbon-carbon double bond and silicon-oxygen bond in the modified resin is 17:9:1.

[0034] The formula preparation process of the three anti-paint is: by weight, 0.06 parts of optical brightener (OB), 0.86 parts of defoamer (BYK UV 3505 acrylate modified polysiloxane), 6 parts of photoinitiator (1-hydroxycyclohexyl phenyl ketone), 12 parts of acrylate monomer (isobornyl acrylate) and 5.6 parts of silane coupling agent (acryloxypropyltrimethoxysilane) were added to the stirrer in sequence, Full...

Embodiment 3

[0036]In this example, 168.19g of hexamethylene diisocyanate, 120g of polyethylene glycol, 180g of hydroxy polydimethylsiloxane and 200g of toluene were added to a three-necked flask, and 0.05g of organotin catalyst was added. ℃ for 2 hours to prepare a prepolymer; then add 60 g of hydroxyethyl methacrylate, react at 65 ℃ for 5 hours, and finally distill the toluene to prepare a silicone-modified urethane acrylate resin. Through testing and calculation, the molar ratio of isocyanate, carbon-carbon double bond and silicon-oxygen bond in the modified resin is 16:10:1.

[0037] The formula preparation process of the three anti-paint is: by weight, 0.08 parts of optical brightener (OB), 0.68 parts of defoamer (BYK UV 3505 acrylate modified polysiloxane), 8 parts of photoinitiator (1-hydroxycyclohexyl phenyl ketone), 8 parts of acrylate monomer (isobornyl acrylate) and 7 parts of silane coupling agent (acryloyloxypropyltrimethoxysilane) were added to the stirrer in sequence, Fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com