Composite coated ternary precursor as well as preparation method and application thereof

A precursor and coating technology, which is applied in electrode manufacturing, electrical components, impregnation manufacturing, etc., can solve the problems of increased risk of material segregation, uneven coating material, and increased difficulty of operation, so as to reduce irreversible phase change, Uniform distribution of coatings and the effect of reducing oxygen defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

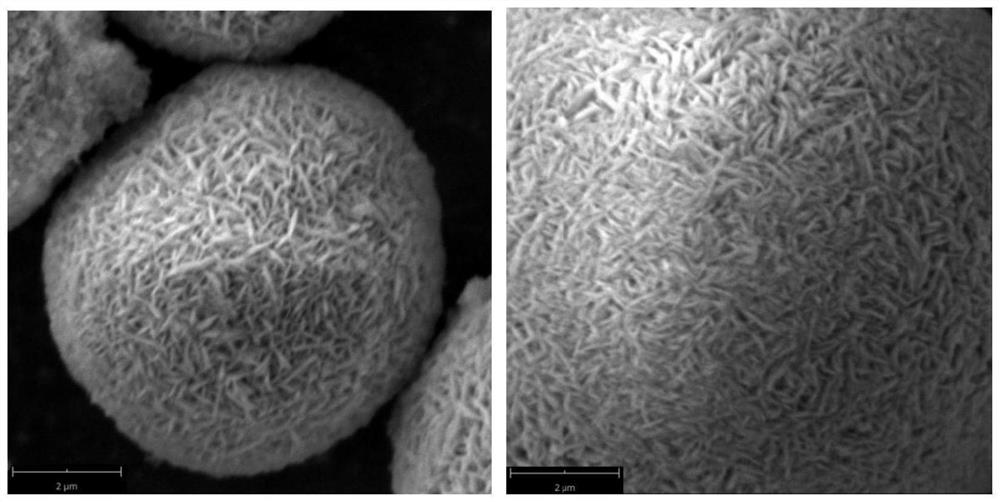

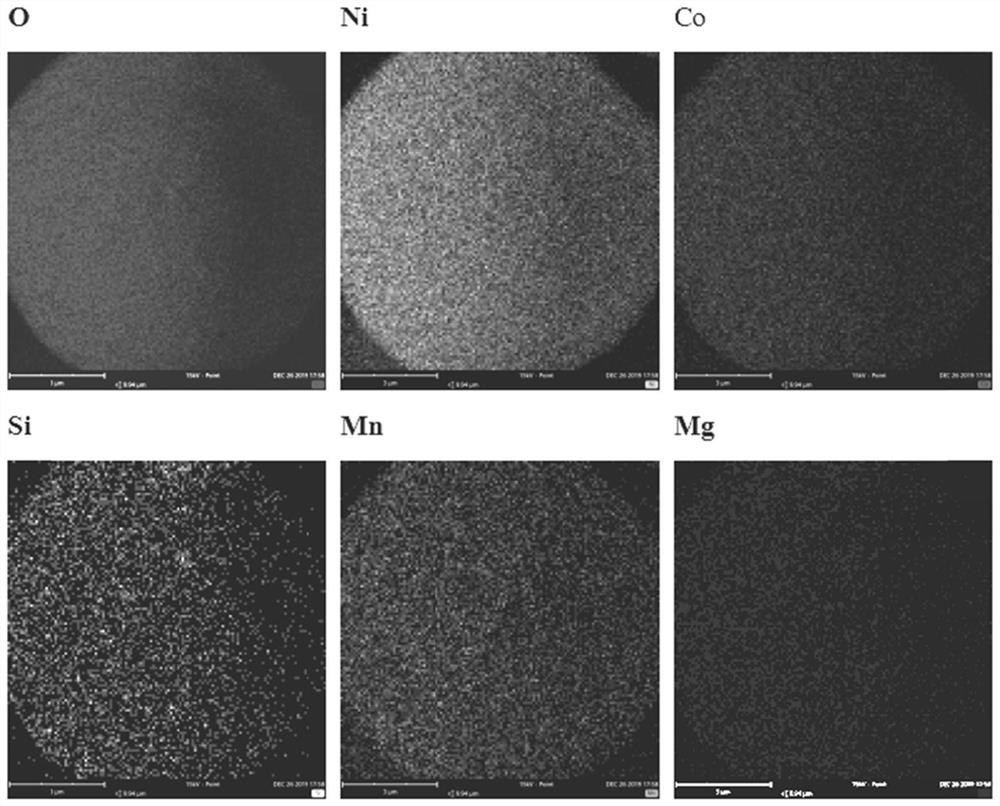

[0032] This example has prepared a compound coated three-membered precursor, and the specific process is:

[0033] (1) Common precipitation prepared three-dollared precursor: Nickel-cobalt manganese mixed solution, precipitant, and complexing agent simultaneously prepared according to the ratio of molar ratio 82: 12: 6 In the reactor, an inert gas atmosphere is maintained, the stirring speed is 300r / min, the temperature is 70 ° C and the reaction pH are 11-12, and the precursor Ni is prepared by a coprecipitation reaction. 0.82 CO 0.12 Mn 0.06 (OH) 2 When the particles grow to 10.5 μm, the pH of the reaction system is adjusted to 7.0-8.0, and the mixture is stopped, and the reaction material is left within the kettle;

[0034] (2) Preparation of 1 mol / L of magnesium sulfate solution and 1 mol / L sodium silicate solution;

[0035] (3) Preparation of a composite coated precursor: Maintaining the stirring speed and temperature of the reaction kettle in step (1) unchanged, 5 L of...

Embodiment 2

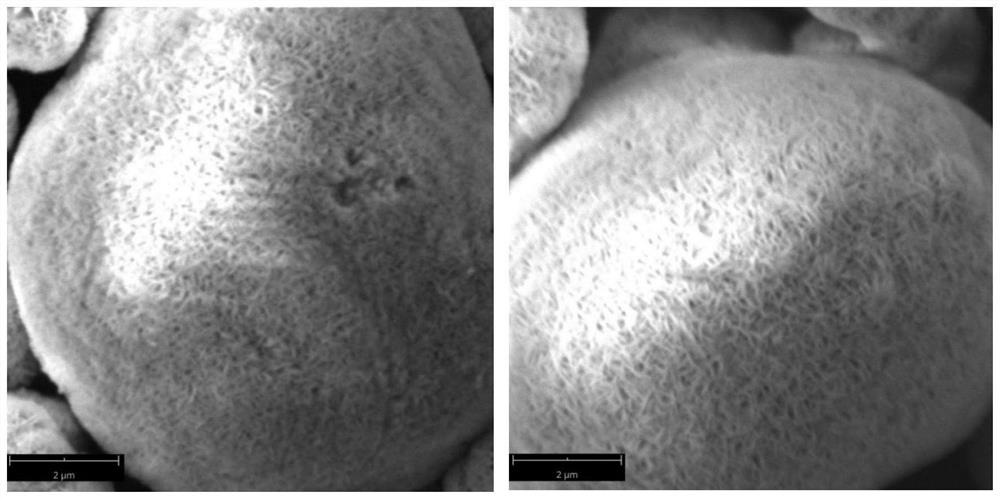

[0040] This example has prepared a compound coated three-membered precursor, and the specific process is:

[0041] (1) Coprecipitation prepared three-membered precursor: nickel sulfate, cobalt sulfate, sulfate, magnesium sulfate mass molar ratio 0.82: 0.12: 0.05: 0.01 is dissolved in pure water, stir well, and formulated into 1.6 mol / L. Mixed metal salt solution; dissolve sodium hydroxide in pure water, then sodium silicate, stir well, and formulated into a doped precipitant of 5 mol / L, wherein the molar ratio of sodium hydroxide with sodium hydroxide is 200: 1; Add a proper amount of pure water to the reactor, turn on stirring and heating, the stirring speed is 300 r / min, the reaction temperature is 65 ° C, and ammonia water is added to the reactor, so that the ammonia concentration in the kettle is 6g / L. Further, a small amount of undoped sodium hydroxide solution regulating the pH of 11.4-11.6, and the nitrogen gas is continuously introduced into the kettle to prevent o...

Embodiment 3

[0046] This example has prepared a compound coated three-membered precursor, and the specific process is:

[0047] (1) Commonly precipitation prepared three-membered precursor: The nickel-cobalt manganese prepared according to 5: 2: 3 is mixed into the reactor, and the inert gas atmosphere is maintained. The stirring speed is 350 r / min, the temperature is 55 ° C and the reaction pH is 11-12, and the precursor Ni is prepared by a coprecipitation reaction. 0.5 CO 0.2 Mn 0.3 (OH) 2 When the particles grow to 5 μm, the pH of the reaction system is adjusted to 7.0-8.0, and the addition is stopped, and the reaction material is left within the kettle;

[0048] (2) Preparation 1.5 mol / L of copper sulfate solution and 1 mol / L of sodium molybdate solution;

[0049] (3) Preparation of composite coated precursors: Maintaining the stirring speed and temperature of the reaction kettle in step (1), the reaction of 3.9L sulfate solution and 5.9L molybdate solution simultaneously into the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com