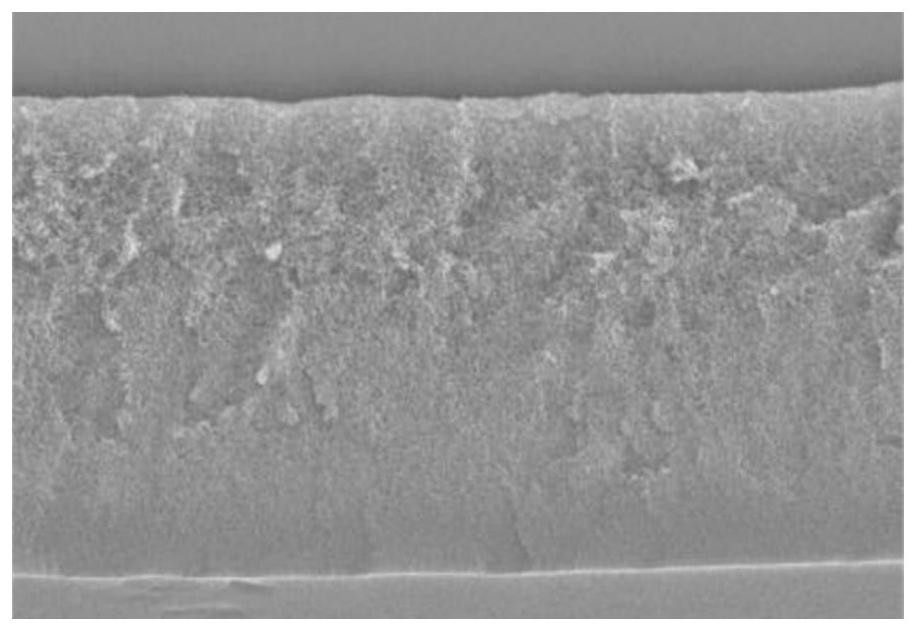

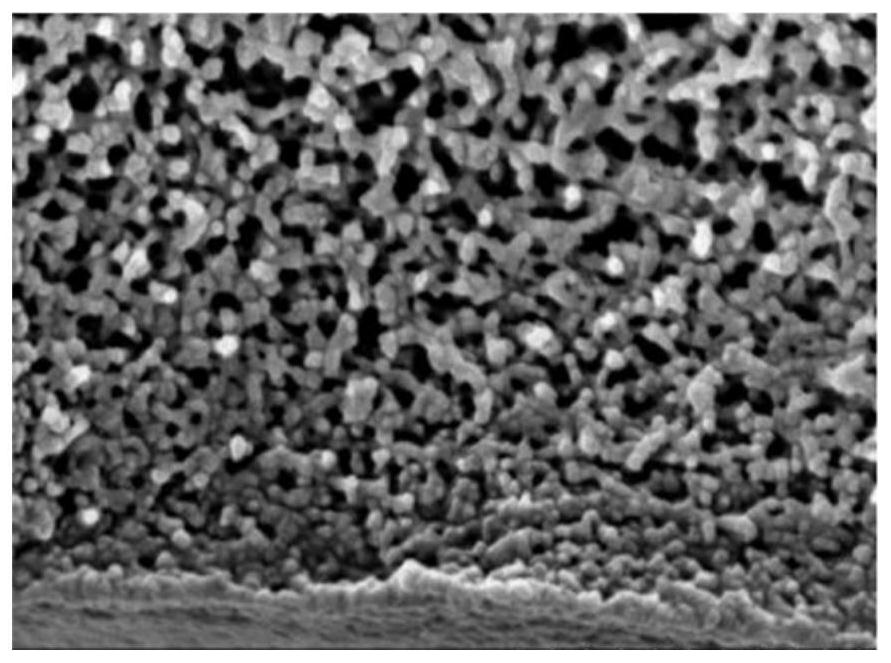

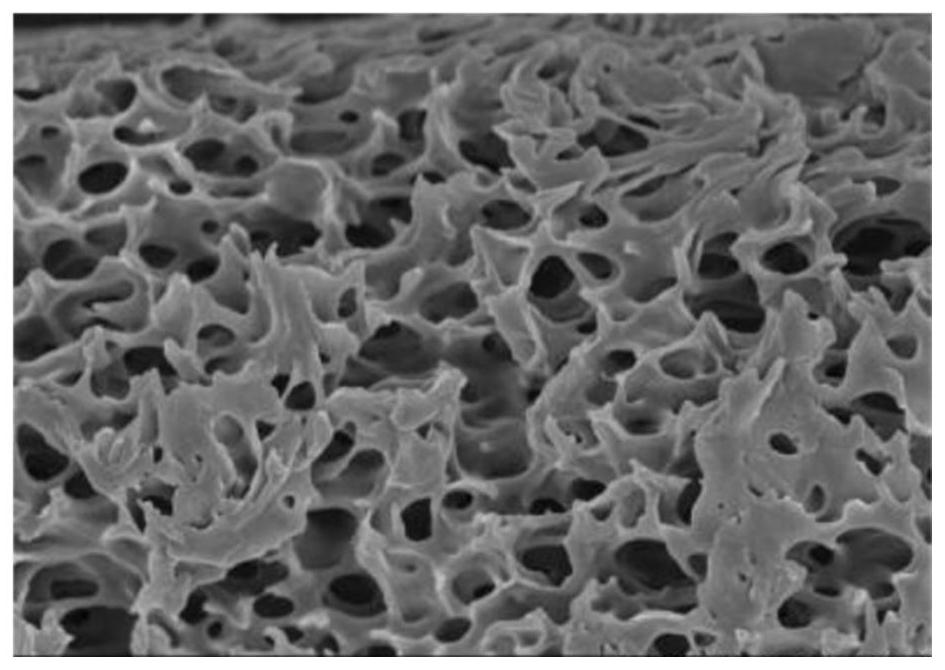

Asymmetric PES porous membrane for virus removal and preparation method thereof

A porous membrane and asymmetric technology, applied in the field of membrane materials, can solve the problems of inability to retain parvovirus, low protein adsorption rate, high risk, etc., and achieve the effect of being suitable for large-scale promotion, high protein yield, and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Embodiment 1 A method for preparing an asymmetric PES porous membrane for virus removal, comprising the steps of:

[0114] S1: Prepare a casting solution, and cast it on a carrier to form a liquid film; wherein the casting solution includes the following components by weight: 15 parts of polyethersulfone; 60 parts of organic solvent; 8 parts of polar additives; The organic solvent is dimethylsulfoxide; the polar additive is polyvinylpyrrolidone;

[0115] S2: Pre-separate the liquid film in air with a temperature of 6°C and a relative humidity of 90% for 3 seconds;

[0116] S3: immerse the pre-phase-separated liquid film together with the carrier in the solidifying liquid for 25 seconds, the solidifying liquid invades the interior of the liquid film and gradually diffuses inward, and then solidifies to form a porous film; the solidifying liquid includes water and osmotic additives, The penetrating additive is a fluorine-containing hydrophilic substance hexafluoroisoprop...

Embodiment 2

[0117] Embodiment 2 A method for preparing an asymmetric PES porous membrane for virus removal, comprising the steps of:

[0118] S1: Prepare a casting solution, and cast it onto a carrier to form a liquid film; wherein the casting solution includes the following components in parts by weight: 17 parts by weight of polyethersulfone; 65 parts of organic solvent; 10 parts of polar additives; Described organic solvent is ethyl acetate; Described polar additive is polyethylene glycol;

[0119] S2: Pre-separate the liquid film in air with a temperature of 8°C and a relative humidity of 86% for 4 seconds;

[0120] S3: immerse the pre-phase-separated liquid film together with the carrier in the solidifying liquid for 30 seconds, the solidifying liquid invades the interior of the liquid film and gradually diffuses inward, and then solidifies to form a porous film; the solidifying liquid includes water and osmotic additives, The penetrating additive is trifluoroethanol, a fluorine-con...

Embodiment 3

[0121] Embodiment 3 A method for preparing an asymmetric PES porous membrane for virus removal, comprising the steps of:

[0122] S1: Prepare a casting solution, and cast it on a carrier to form a liquid film; wherein the casting solution includes the following components by weight: 19 parts of polyethersulfone; 70 parts of organic solvent; 12 parts of polar additives;

[0123] The organic solvent is caprolactam; the polar additive is polyethyleneimine;

[0124] S2: Pre-separate the liquid film in air with a temperature of 10°C and a relative humidity of 82% for 5 seconds;

[0125] S3: Immerse the pre-phase-separated liquid film together with the carrier in the solidification solution for 35 seconds, the solidification solution invades the interior of the liquid film and gradually diffuses inwards, and then solidifies to form a porous film; the solidification solution includes water and osmotic additives, The penetrating additive is a fluorine-containing hydrophilic substance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com