Alpha-hydroxy-2-ethylhexyl phosphinic acid extracting agent as well as preparation method and application thereof

A technology of base phosphinic acid and extractant, which is applied in the field of α-hydroxy-2-ethylhexylphosphinic acid extractant and its preparation, can solve the problems of easy occurrence of side reactions, high toxicity and the like, and achieves easy industrial popularization and application , good selectivity, the effect of improving extraction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of α-Hydroxy-2-Ethylhexylphosphinic Acid

[0037] 1) Take 47.4mL (288mmol) of 2-ethylhexylaldehyde, 47.0mL (432mmol) of 50% hypophosphorous acid, 6mL of concentrated hydrochloric acid, and 70mL of 1,4-dioxane in a reaction flask, add a magnet, heat, and condense Reflux and react at 80°C for 5h;

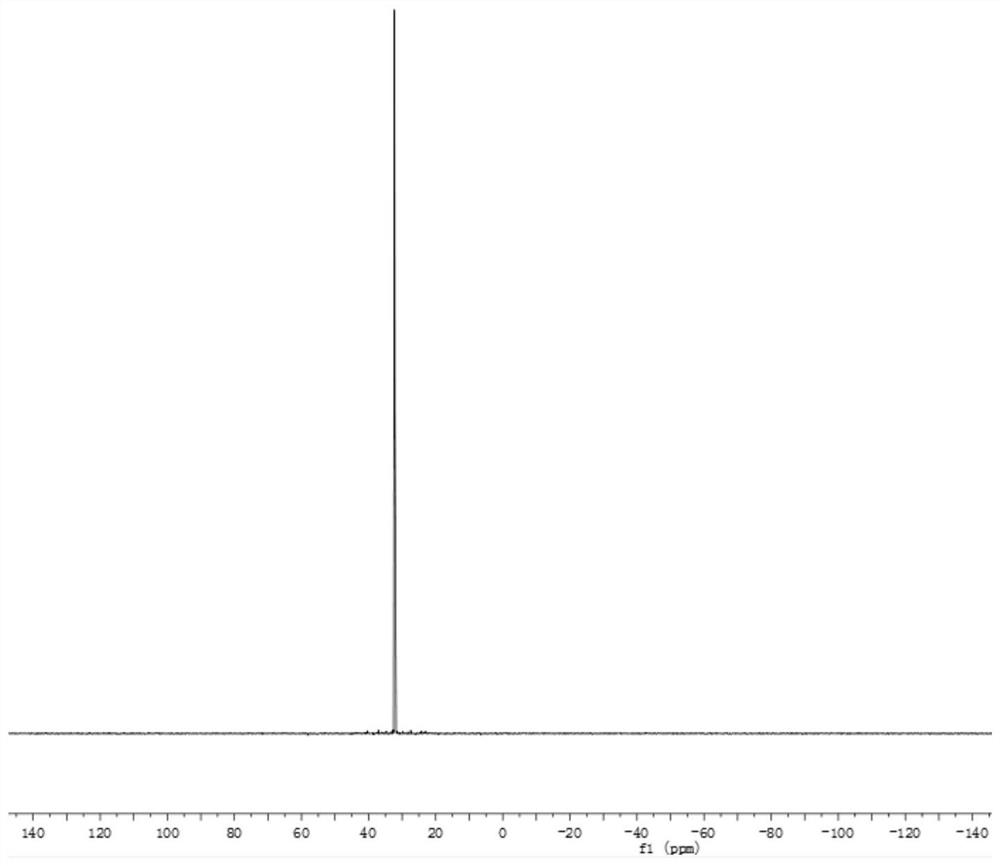

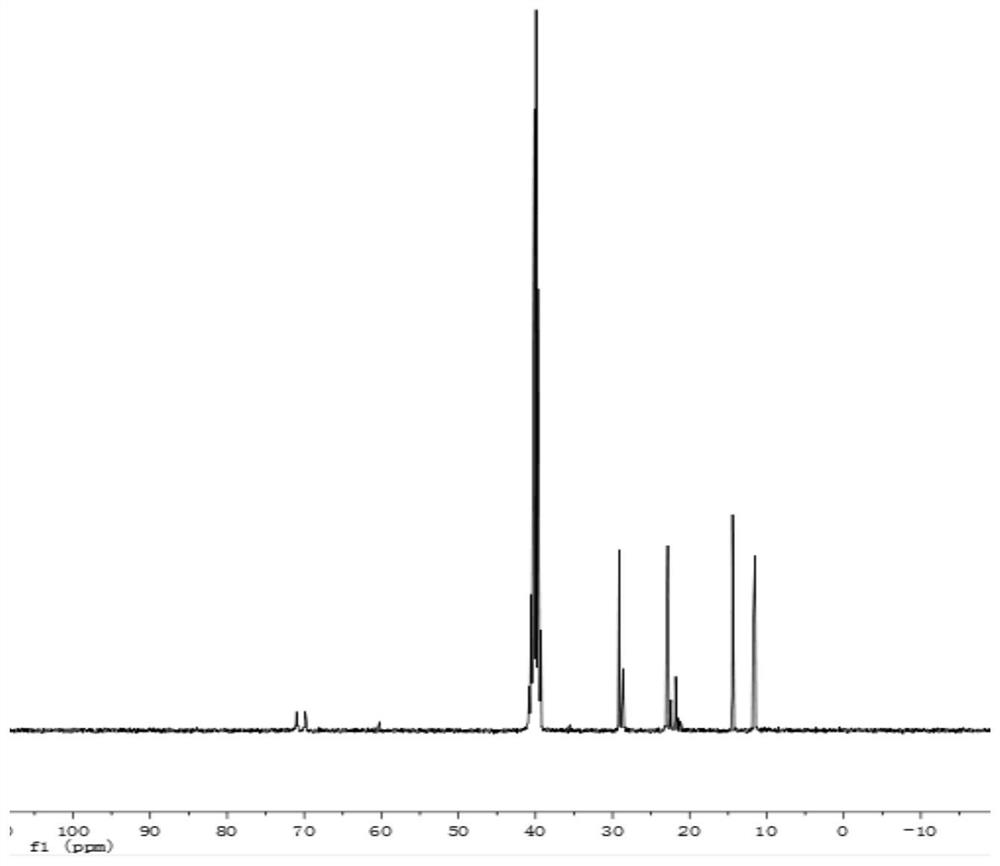

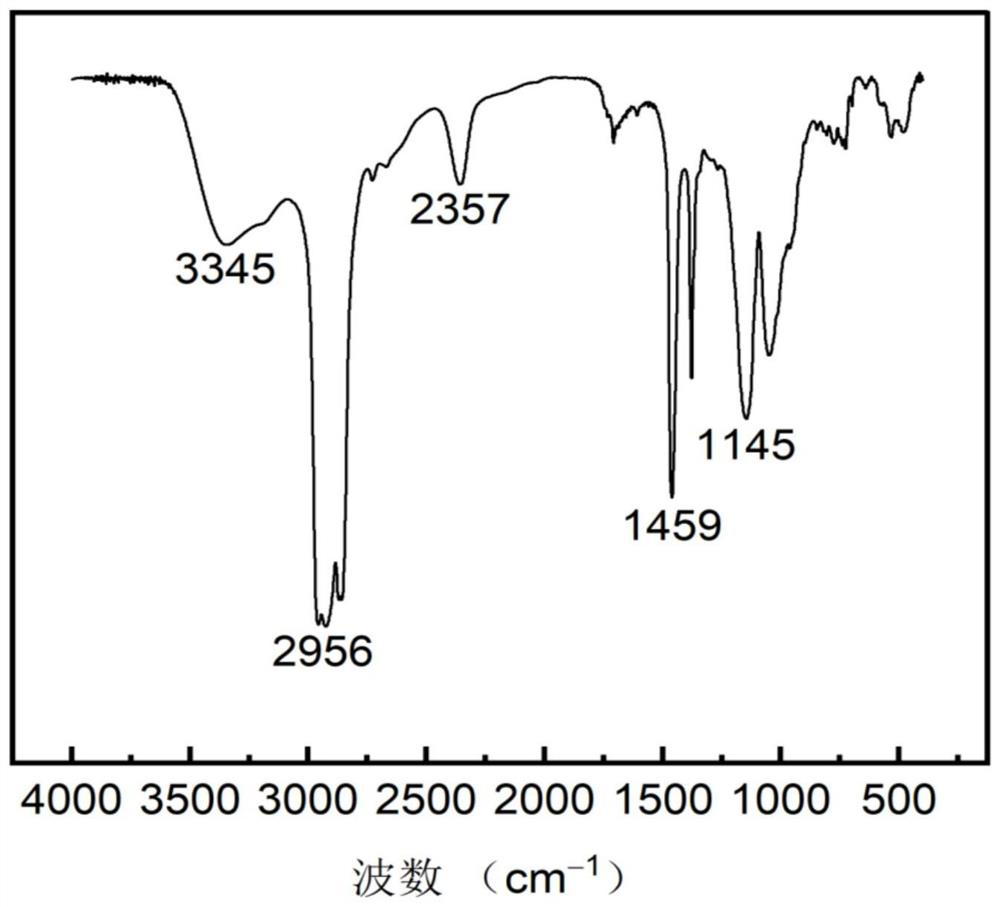

[0038] 2) The reacted mixture was lowered to room temperature, washed several times with 10% aqueous sodium hydroxide solution until the pH of the aqueous phase was >10, and the aqueous phase was combined and retained. The aqueous phase was acidified to pH31 The results of P NMR spectrum analysis are as follows: figure 1 as shown, 13 The results of C NMR spectrum analysis are as follows: figure 2 Shown, the infrared spectrum analysis result of α-hydroxyl-2-ethylhexylphosphinic acid is as follows image 3 As shown, the mass spectrometric analysis results of α-hydroxy-2-ethylhexylphosphinic acid are as follows Figure 4 As shown, the analysis results confirmed t...

Embodiment 2

[0040] Preparation of α-Hydroxy-2-Ethylhexylphosphinic Acid

[0041] 1) Take 47.4mL (288mmol) of 2-ethylhexylaldehyde, 47.0mL (432mmol) of 50% hypophosphorous acid, 5mL of concentrated sulfuric acid, and 70mL of tetrahydrofuran in a reaction flask, add a magnet, heat, condense and reflux, and react at 90°C 5h;

[0042] 2) The reacted mixture was lowered to room temperature, washed several times with 10% aqueous sodium hydroxide solution until the pH of the aqueous phase was >10, and the aqueous phase was combined and retained. The aqueous phase was acidified to pH<3 with 10% sulfuric acid, extracted three times with 30 mL of ethyl acetate, and the organic phase was combined and retained. Finally, the organic phase was washed three times with saturated brine, dried over anhydrous sodium sulfate, filtered, and distilled under reduced pressure at 55° C. to obtain a light yellow transparent oily liquid with a yield of 81.44%.

Embodiment 3

[0044] Extraction Performance of α-Hydroxy-2-Ethylhexylphosphinic Acid for Manganese and Magnesium

[0045] Mn in manganese magnesium solution 2+ The concentration is 5.5g / L, Mg 2+ The concentration is 2.4g / L, and the extractants are α-hydroxy-2-ethylhexylphosphinic acid, α-hydroxyoctylphosphinic acid, P204, α-hydroxy-2-ethylhexylphosphinic acid, P204 The diluent is kerosene, and the diluent of α-hydroxyoctylphosphinic acid is acetone. The extractant and the diluent are mixed to form an organic phase, the concentration of the extractant is 20%, and the organic phase is saponified by 30% aqueous sodium hydroxide solution, and the saponification rate is 30%; the organic phase and the manganese-magnesium solution are mixed, O / A=1:2, the extraction time is 10min, and the standing time is 30min; after the primary extraction, the extraction rates of manganese and magnesium in the manganese-magnesium mixed solution by the three extraction systems are shown in Table 1. As can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com